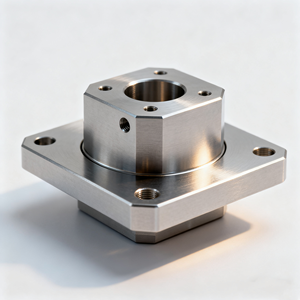

Rapid Prototype Cnc Machining

Top sponsor listing

Top sponsor listing

About rapid prototype cnc machining

Where to Find Rapid Prototype CNC Machining Suppliers?

China remains the global hub for rapid prototype CNC machining services, with key supplier clusters concentrated in Zhejiang, Jiangsu, and Shandong provinces. These regions host vertically integrated manufacturing ecosystems that combine precision machining infrastructure with agile prototyping capabilities. Ningbo and Huzhou in Zhejiang province feature dense networks of job shops specializing in low-volume, high-mix production, enabling fast turnaround for custom prototypes. Meanwhile, suppliers in Qingdao (Shandong) leverage proximity to port logistics and large-scale industrial parks to support both prototype development and subsequent volume scaling.

The regional advantage lies in tightly coordinated supply chains—ranging from raw material sourcing to surface treatment and assembly—that reduce lead times by 25–40% compared to Western counterparts. Most facilities operate multi-axis CNC lathes and milling centers capable of tolerances down to ±0.005mm, serving industries such as automotive R&D, medical devices, and consumer electronics. With average MOQs starting at one piece and standard lead times of 5–10 days for prototypes, these suppliers offer flexibility for iterative design validation and small-batch testing prior to mass production.

How to Choose Rapid Prototype CNC Machining Suppliers?

Selecting a reliable partner requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to multi-axis CNC machining (3-axis, 4-axis, or 5-axis) and compatibility with required materials—including aluminum alloys (6061, 7075), stainless steel (303, 316), brass, titanium, and engineering plastics (ABS, PC, POM). Suppliers should provide detailed process documentation, including toolpath simulation and first-article inspection reports. For functional prototypes, verify secondary processing capabilities such as anodizing, plating, laser engraving, or heat treatment.

Production Readiness Assessment

Evaluate core performance indicators:

- In-house machining capacity with documented machine utilization rates

- Demonstrated ability to maintain tight tolerances (±0.01mm typical for prototypes)

- Response time under 6 hours and on-time delivery rate exceeding 90%

- Support for digital file formats (STEP, IGES, DWG, STL) and DFM feedback within 24 hours

Cross-reference service claims with actual product listings and pricing structures to assess consistency and scalability.

Quality & Transaction Assurance

Prioritize suppliers offering dimensional inspection reports (CMM or optical measurement) and adherence to ISO 9001 quality management standards. While not all providers list formal certifications, consistent on-time delivery and reorder rates above 15% indicate operational reliability. Use secure payment mechanisms and request physical or digital samples before committing to larger runs. Confirm packaging protocols to prevent transit damage for delicate machined components.

What Are the Best Rapid Prototype CNC Machining Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Sample MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Ningbo Keda Seiko Technology Co., Ltd. | Machining Services (116), Casting Services (140) | 100% | ≤16h | - | - | Color, material, size, logo, packaging, label, graphic | 1 pc | $0.10–$3.89 |

| Huzhou Dear Industry Co., Ltd. | Machining Services (varied) | 100% | ≤6h | 50% | US $360,000+ | Color, TPU/EPDM material, hardness, 3D drawings, injection | 1 pc | $0.10–$1.20 |

| SkyReach Intelligent MFG Limited | Machining Services (varied) | 87% | ≤3h | 15% | US $30,000+ | Color, material, size, logo, packaging, label, graphic | 1 pc | $0.50–$3.89 |

| Kagoshimaseiki Co.,Ltd | Machining Services (490) | - | ≤2h | - | - | Not specified | 1 pc | $0.05–$0.90 |

| 24K Investment (Qingdao) Co., Ltd. | Machining Services (166), Sheet Metal Fabrication | 94% | ≤2h | 20% | US $10,000+ | Material, size, logo, packaging, label, graphic | 1 pc | $0.01–$1.00 |

Performance Analysis

Huzhou Dear Industry stands out with a 50% reorder rate and strong customization depth, particularly in elastomeric materials and injection-related design support, indicating high client satisfaction for complex prototype requirements. SkyReach and 24K Investment demonstrate fast response times (≤3h) and solid delivery performance (94% and 87%), suitable for time-sensitive development cycles. Kagoshimaseiki offers the lowest price point ($0.05/unit) and extremely rapid inquiry handling, though lack of verified delivery and revenue data increases due diligence requirements. Ningbo Keda Seiko’s 100% on-time record and broad casting integration suggest capability for hybrid prototype-to-production workflows.

FAQs

What materials are commonly used in rapid prototype CNC machining?

Aluminum 6061-T6 and 7075-T6 are most common for lightweight structural prototypes. Stainless steel (303, 316) is preferred for corrosion-resistant applications. Plastics like ABS, polycarbonate (PC), acetal (POM/Delrin), and nylon offer favorable strength-to-weight ratios and machinability for non-metallic functional models.

What is the typical lead time for CNC rapid prototypes?

Standard lead times range from 5 to 10 business days, depending on part complexity and finishing requirements. Express services may reduce this to 3–5 days at a premium. Additive steps like anodizing or passivation can extend timelines by 2–3 days.

Do suppliers support design for manufacturability (DFM) feedback?

Yes, leading suppliers provide free DFM analysis upon receipt of CAD files. This includes recommendations on wall thickness, tolerance stack-up, tool access, and cost-reduction opportunities, typically delivered within 24 hours of inquiry.

Are samples available before full production?

Most suppliers offer single-piece sampling with no additional fee beyond unit cost. Samples serve to validate geometry, fit, finish, and material properties before batch release. Digital inspection reports are often included upon request.

Can CNC machining be combined with other prototyping methods?

Yes, many suppliers integrate CNC with 3D printing and sheet metal fabrication for hybrid prototyping. This allows selective use of high-precision machining for critical features while using additive processes for complex geometries or internal channels, optimizing cost and speed.