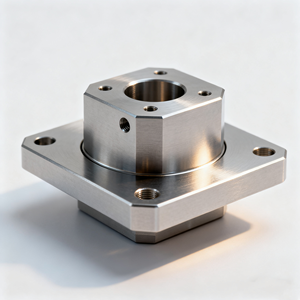

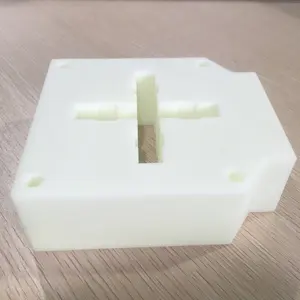

Rapid Prototyping Cnc Machining

Top sponsor listing

Top sponsor listing

1/18

1/18

1/21

1/21

1/24

1/24

1/20

1/20

1/17

1/17

About rapid prototyping cnc machining

Where to Find Rapid Prototyping CNC Machining Suppliers?

China remains a dominant hub for rapid prototyping and CNC machining services, with key supplier clusters concentrated in the Pearl River Delta and Yangtze River Delta regions. Shenzhen and Hangzhou serve as primary centers due to their advanced manufacturing ecosystems, skilled engineering workforces, and proximity to material suppliers and logistics networks. These regions support high-mix, low-to-medium volume production ideal for prototyping and iterative design development.

Suppliers in these zones operate within vertically integrated environments that combine 3-, 4-, and 5-axis CNC machining, turning, sheet metal fabrication, and casting under one roof. This integration enables seamless transitions from prototype to small-batch production, reducing lead times by up to 40% compared to fragmented supply chains. Buyers benefit from localized access to secondary processes such as anodizing, sandblasting, polishing, and precision metrology, all critical for functional and cosmetic validation of prototypes.

The region’s mature industrial infrastructure supports rapid turnaround—typical lead times range from 7 to 15 days for machined prototypes, depending on complexity and material availability. Cost efficiency is further enhanced by competitive labor rates and economies of scale in tooling and fixturing, offering 20–35% lower pricing than equivalent services in North America or Western Europe.

How to Choose Rapid Prototyping CNC Machining Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Equipment

Verify the supplier’s access to multi-axis CNC systems (3-, 4-, and 5-axis) and lathe capabilities for complex geometries. Advanced providers offer both milling and turning operations in-house, minimizing outsourcing risks. Confirm compatibility with required materials—including aluminum (6061, 7075), stainless steel (303, 316), brass, titanium, and engineering plastics (ABS, POM, PC, PEI). Dimensional accuracy should be validated at ±0.005 mm or tighter for precision applications.

Quality Assurance & Compliance

Prioritize suppliers with documented quality management systems. While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and repeat order rates exceeding 40% indicate operational discipline. Request evidence of inspection protocols, including first-article inspection reports (FAIR), coordinate measuring machine (CMM) data, and surface finish testing. For export-bound parts, ensure compliance with RoHS or other applicable regulatory standards if required.

Customization and Design Support

Evaluate the supplier’s ability to handle full-cycle customization—from CAD drawing interpretation to post-processing options like color coding, labeling, packaging, and surface treatments (anodized, electroplated, powder coated). Leading providers support digital file formats (STEP, IGES, DWG) and offer rapid feedback loops for design for manufacturability (DFM) analysis within 24 hours.

Transaction Reliability Metrics

Use performance indicators embedded in supplier profiles as proxies for reliability:

- On-time delivery rate ≥96%

- Reorder rate >25% indicates customer retention

- Average response time ≤3 hours reflects operational responsiveness

- Online transaction volume (e.g., >US $180,000/year) suggests market validation

Cross-reference product listings with minimum order quantities (MOQs) as low as 1 piece, confirming suitability for prototype-scale orders. Avoid suppliers with inconsistent MOQs or price brackets lacking transparency.

What Are the Best Rapid Prototyping CNC Machining Suppliers?

| Company Name | Type | Main Services | On-Time Delivery | Reorder Rate | Response Time | Annual Online Revenue | Customization Scope | Min. Order |

|---|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Custom Manufacturer | Machining, Casting, Sheet Metal | 100% | 25% | ≤1h | US $1.9M+ | 5-axis, anodizing, drawing, logo, size, material, finish | 1–2 pcs |

| Hangzhou Aoyi Trade Co., Ltd. | Multispecialty Supplier | CNC Machining, 3D Scanning, SLA, PolyJet | 96% | 54% | ≤3h | US $180K+ | 3D scanning, resin printing, DLP/DLS, TPEE, cobalt-chrome, full-color printing | 1 pc |

| Huzhou Dear Industry Co., Ltd. | Multispecialty Supplier | CNC Machining, Injection Molding | 100% | 48% | ≤6h | US $360K+ | TPU, EPDM, hardness control, 3D drawings, graphic, injection | 1–2 pcs |

| 24K Investment (Qingdao) Co., Ltd. | Not Specified | Machining, Sheet Metal, Moulds, Casting | 94% | 20% | ≤2h | US $10K+ | Limited customization data | 100 cm / 1 dozen |

| SkyReach Intelligent MFG Limited | Custom Manufacturer | CNC Machining, Large-Scale Parts | 78% | <15% | ≤3h | US $30K+ | Material, size, logo, packaging, graphic | 1 pc |

Performance Analysis

ShenZhen Selection Hardware and Huzhou Dear Industry demonstrate strong operational reliability with 100% on-time delivery and robust customization capabilities, making them suitable for time-sensitive prototyping cycles. Hangzhou Aoyi stands out with a 54% reorder rate—the highest among listed suppliers—indicating strong client satisfaction, supported by advanced additive technologies like SLA, PolyJet, and DLP, which complement traditional CNC workflows for hybrid prototyping.

While SkyReach offers low MOQs and large-part machining, its 78% on-time delivery and sub-15% reorder rate suggest potential fulfillment inconsistencies. Similarly, 24K Investment reports minimal online revenue and higher MOQs measured in centimeters or dozens, indicating a focus on semi-finished components rather than discrete prototypes. Buyers seeking full-service rapid prototyping should prioritize suppliers offering integrated digital design validation, material diversity, and transparent per-unit pricing.

FAQs

How to verify rapid prototyping CNC machining supplier reliability?

Assess on-time delivery history, reorder rate, and response time as leading indicators of service consistency. Request sample parts with traceable inspection reports. Conduct virtual audits to confirm in-house machining capacity and quality control stations. Validate technical communication proficiency through DFM feedback speed and clarity.

What is the typical lead time for CNC-machined prototypes?

Standard lead times range from 7 to 12 days after design approval. Complex multi-axis or large-scale parts may require 14–18 days. Expedited services (3–5 days) are available from top-tier suppliers, often at a 20–30% premium.

Do suppliers support prototyping with functional materials?

Yes. Most suppliers offer engineering-grade metals and plastics suitable for mechanical, thermal, and environmental testing. Common options include aluminum 6061-T6, stainless steel 316L, PEEK, Delrin (POM), and polycarbonate. Confirm material certifications upon request.

Can I order a single prototype piece?

Absolutely. All top-performing suppliers listed accept MOQs of 1 piece, particularly for prototyping. Pricing is typically structured per unit with no setup surcharge, enabling cost-effective design iteration.

What file types are accepted for CNC prototyping?

Standard formats include STEP (.stp), IGES (.igs), SolidWorks (.sldprt), DWG, DXF, and PDF drawings. Some suppliers also accept STL files for hybrid CNC/3D machining workflows. Ensure files include tolerances, surface finishes, and material specifications.