Rapid Prototype Machining Corp

Top sponsor listing

Top sponsor listing

About rapid prototype machining corp

Where to Find Rapid Prototype Machining Suppliers?

China remains the global hub for rapid prototype machining services, with key supplier clusters concentrated in manufacturing-intensive regions such as Shenzhen, Dongguan, and Hangzhou. These cities form part of the Pearl River Delta and Yangtze River Delta industrial zones—areas renowned for their advanced metalworking infrastructure, skilled engineering labor pools, and dense networks of CNC machining centers and additive manufacturing facilities. Shenzhen alone hosts over 1,200 precision machining workshops, many integrated into larger supply chains serving electronics, medical devices, and automotive R&D sectors.

The region’s ecosystem enables agile prototyping cycles, with suppliers offering turnaround times as fast as 3–7 days for CNC-machined parts and 2–5 days for 3D-printed prototypes. Vertical integration—from raw material sourcing to post-processing treatments like anodizing, polishing, and coating—reduces dependency on external vendors, minimizing delays. Buyers benefit from localized tooling and fabrication expertise, allowing for cost-efficient low-volume production (typically 1–500 units) at 30–50% lower costs compared to North American or European providers.

How to Choose Rapid Prototype Machining Suppliers?

Selecting a reliable partner requires rigorous evaluation across technical, operational, and transactional dimensions:

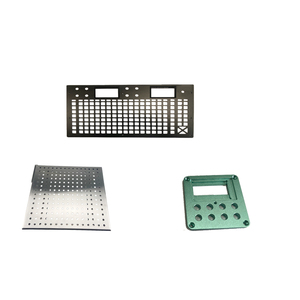

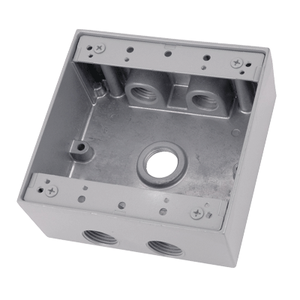

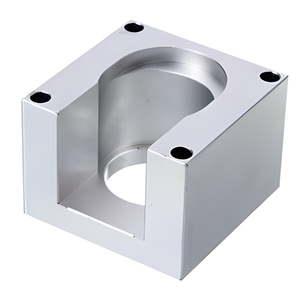

Technical Capabilities & Process Range

Verify access to multi-axis CNC milling, turning, wire EDM, and sheet metal fabrication. Leading suppliers also integrate additive technologies including SLA, SLS, DLP, and PolyJet for high-detail plastic prototypes. Confirm support for critical materials: aluminum (6061, 7075), stainless steel (303, 316), brass, titanium, and engineering plastics (ABS, PC, PEEK, PEBA). Surface treatment options such as bead blasting, electroplating, dark chrome coating, and Pantone-matched painting indicate advanced finishing capacity.

Quality Assurance & Compliance

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating consistent quality through documented inspection protocols. Look for dimensional accuracy within ±0.005 mm for CNC work and layer resolution down to 25 µm in resin printing. Reorder rates above 45% and on-time delivery exceeding 95% serve as proxy indicators of process reliability and customer satisfaction.

Customization & Engineering Support

Assess digital workflow compatibility: STL, STEP, IGES file handling, design-for-manufacturability (DFM) feedback, and rapid quotation systems. Top-tier suppliers offer free design validation and suggest modifications to reduce cost or improve functionality. Customization depth—including logo engraving, swappable components, rubber overmolding, and wireless connectivity integration—reflects technical maturity.

Transaction Metrics & Responsiveness

Response time under 3 hours correlates strongly with proactive order management. Cross-reference online revenue estimates (e.g., US $180,000+ annually) with product listing volume to gauge business scale. Suppliers with dedicated R&D teams typically provide faster iteration cycles and better NDA-compliant IP protection during development phases.

What Are the Best Rapid Prototype Machining Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order Quantity | Price Range (USD) | Specializations |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Runze Metal Technology Co., Ltd. | Sheet Metal Fabrication (574) | 96% | 48% | ≤3h | US $1.7M+ | 1 pc | $0.50–50 | Stamping, die casting, assembly, color packaging, metal tubes |

| Dongguan Jingrui Intelligent Manufacturing Co., Ltd. | Machining Services (648) | 85% | 33% | ≤2h | US $4,000+ | 1 pc | $1.20–50 | High-precision CNC, SLA 3D printing, plastic fabrication |

| Hangzhou Aoyi Trade Co., Ltd. | Plastic Crafts (145) | 96% | 57% | ≤3h | US $180,000+ | 1–5 pcs | $0.99–5.50 | SLA/DLP 3D printing, anime figures, resin casting, full-color printing |

| Huzhou Dear Industry Co., Ltd. | Rapid Prototyping (Multiple) | 100% | 48% | ≤6h | US $370,000+ | 1–100 pcs | $0.10–100 | Resin prototyping, TPU/EPDM materials, injection molding support |

| JINKE VIETNAM INDUSTRIAL COMPANY LIMITED | Machining Services (827) | 91% | - | ≤2h | US $3,000+ | 100 pcs | $0.10–1.50 | Titanium/aluminum/brass CNC machining, 5-axis capabilities |

Performance Analysis

Shenzhen Runze leads in production breadth with extensive sheet metal capabilities and strong reorder metrics, making it suitable for hybrid metal-plastic assemblies. Huzhou Dear Industry stands out with perfect on-time delivery and flexible pricing, ideal for startups requiring small-batch functional testing. JINKE Vietnam offers competitive per-unit pricing but enforces higher MOQs, favoring mid-volume runs. Hangzhou Aoyi excels in aesthetic prototyping—particularly for consumer-facing products—with full-color printing and intricate surface detailing. Dongguan Jingrui provides fast response times and broad machining capacity, though its lower reorder rate suggests room for service consistency improvement.

FAQs

What is the typical lead time for rapid prototype machining?

CNC machining lead times range from 3–7 days depending on complexity and material availability. 3D-printed prototypes can be delivered in 2–5 days. Additive methods like SLA or DLP are faster for complex geometries unsuitable for traditional cutting.

Do suppliers accept single-piece orders?

Yes, most suppliers listed accept minimum orders of 1 piece, particularly for CNC and 3D printing services. However, unit prices decrease significantly at volumes above 100 pieces due to setup amortization.

Are surface finish and color customization available?

Yes, common options include anodizing (Type II/III), powder coating, sandblasting, mirror polishing, and Pantone-matched spray painting. Decals, laser engraving, and graphic overlays are supported for branding or UI elements.

Can I get design assistance before production?

Many suppliers offer free design review and manufacturability feedback. Submit CAD files in STEP, IGES, or STL format to receive DFM reports highlighting potential issues related to wall thickness, draft angles, or stress concentrations.

How are intellectual property and confidentiality handled?

Buyers should request signed NDAs prior to sharing sensitive designs. Reputable suppliers maintain secure data transfer protocols and restrict access to project files. For high-risk innovations, consider splitting components across multiple vendors to limit exposure.