Prototype Machine Shop Near Me

Top sponsor listing

Top sponsor listing

HK

HK

About prototype machine shop near me

Where to Find Prototype Machine Shop Suppliers?

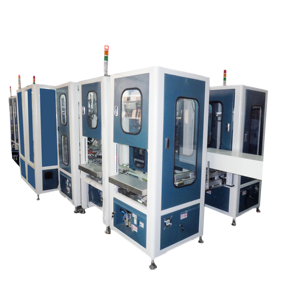

China's rapid prototyping sector is anchored in the Pearl River Delta region, where Shenzhen and Guangzhou serve as primary hubs for precision manufacturing. These cities host vertically integrated prototype machine shops equipped with CNC machining, 3D printing, vacuum casting, and sheet metal fabrication capabilities. Proximity to material suppliers and electronics OEMs enables streamlined workflows, reducing component lead times by 25–40% compared to decentralized production networks.

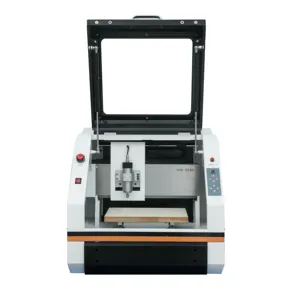

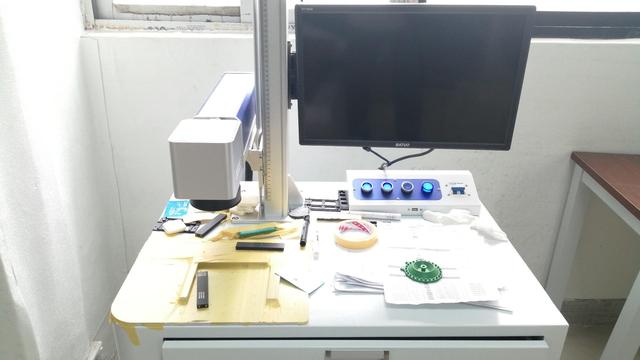

The region’s ecosystem supports both low-volume prototyping and small-batch production, with facilities commonly operating multi-axis CNC centers, SLA/DLP 3D printers, and laser cutting systems. Average shop floor areas range from 1,000 to 5,000m², allowing scalability for engineering teams requiring iterative design validation or functional testing. Buyers benefit from localized supply chains that maintain 96–100% on-time delivery performance and response times under four hours, critical for accelerating product development cycles.

How to Choose Prototype Machine Shop Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

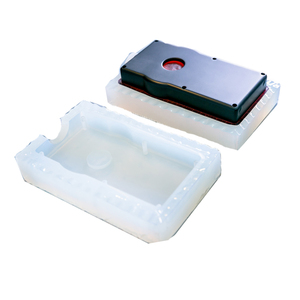

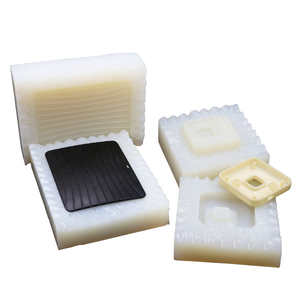

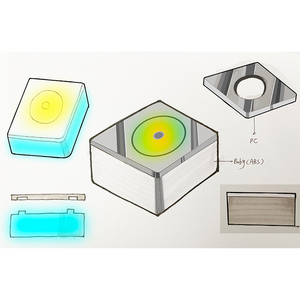

Confirm access to core prototyping technologies: CNC milling (3–5 axis), additive manufacturing (SLA, SLS, FDM), and secondary processes like surface finishing, anodizing, or painting. Suppliers should support common file formats (STL, STEP, IGES) and offer material compatibility with ABS, PC, nylon, aluminum 6061, and stainless steel. For electronic enclosures or robotics prototypes, verify experience with RIM (Reaction Injection Molding) or urethane casting.

Production & Quality Assurance Metrics

Evaluate key performance indicators derived from verified transaction data:

- On-time delivery rate ≥98%

- Average response time ≤3 hours

- Reorder rate >40%, indicating customer retention

- Minimum order quantity (MOQ) of 1 piece for prototype flexibility

While formal ISO 9001 certification is not universally listed, consistent on-time delivery and repeat business suggest de facto adherence to quality management principles. Request process documentation, including first-article inspection reports or dimensional tolerance validation (typically ±0.05mm for CNC parts).

Customization and Lead Time Management

Assess customization scope beyond geometry—options such as Pantone color matching, electroplating, sandblasting, or transparent polycarbonate finishes are available among top-tier providers. Typical lead times range from 3–7 days for CNC prototypes and 2–5 days for 3D-printed models. Suppliers offering workshop planning support or design-for-manufacturability feedback add value during early-stage development.

Transaction Security and Export Readiness

Prioritize suppliers with documented export histories and online revenue transparency (ranging from US $10,000 to over $120,000 annually). Use secure payment mechanisms and request sample prototypes before full-scale engagement. Validate packaging standards and labeling compliance for international shipments, particularly for sensitive materials or painted components.

What Are the Best Prototype Machine Shop Suppliers?

| Company Name | Location | Main Processes | Materials Supported | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Extension Electromechanical Co., Ltd. | Shenzhen, CN | CNC, Welding, Screen Printing | Steel, Electronics Components | 100% | ≤2h | US $120,000+ | 41% | 1 pc |

| Guangzhou Seal Laser Rapid Prototype Co., Ltd. | Guangzhou, CN | 3D Printing, Vacuum Casting | PA, PU, Rubber, Plastic | 100% | ≤3h | US $10,000+ | <15% | 1 pc |

| Shenzhen Strongd Model Technology Co., Ltd. | Shenzhen, CN | CNC, 3D Print, Broaching | Steel, Polypropylene, Metal | 98% | ≤2h | US $50,000+ | 43% | 1 pc |

| Guangzhou Gaojie Model Design And Manufacturing Co., Ltd. | Guangzhou, CN | 3D Print, Silicone Molding | ABS, PETG, PC, Resin | 96% | ≤4h | US $80,000+ | 51% | 1 pc |

| Shanghai Yunyan Prototype And Mould Manufacture Factory | Shanghai, CN | CNC, SLM 3D Printing | Aluminum 6061, TPU, Nylon | 100% | ≤3h | US $60,000+ | 41% | 1 pc |

Performance Analysis

Shenzhen- and Guangzhou-based suppliers dominate responsiveness and reorder metrics, reflecting strong service consistency. Shenzhen Extension Electromechanical leads in reported online revenue and achieves perfect on-time delivery, suggesting robust operational control. Guangzhou Gaojie stands out with a 51% reorder rate—the highest in the cohort—indicating high client satisfaction despite a slightly longer response window. Shanghai Yunyan offers specialized expertise in industrial-grade aluminum prototypes and SLM metal printing, suitable for mechanical or robotic applications requiring structural integrity. Buyers seeking cosmetic or translucent prototypes should prioritize Guangzhou Gaojie for its broad finish options, including polishing, painting, and splicing techniques.

FAQs

How to verify prototype machine shop reliability?

Analyze on-time delivery records, reorder rates, and response times as proxies for operational stability. Request digital facility walkthroughs to confirm ownership of stated equipment. Validate material traceability and inspect sample parts for dimensional accuracy and surface quality.

What is the typical prototyping lead time?

CNC-machined parts typically require 3–7 days; 3D-printed prototypes can be delivered in 2–5 days. Expedited services may reduce timelines by 30–50% at premium rates. Add 3–7 days for surface treatments or assembly.

Do suppliers support one-off custom prototypes?

Yes, all listed suppliers accept minimum orders of 1 piece, catering specifically to R&D teams and startups requiring single-unit validation without tooling investment.

Can I request specific material certifications?

While RoHS or material test reports are not standard, leading suppliers provide technical datasheets upon request. For regulated industries, specify requirements upfront to confirm availability of certified raw materials.

How are design files protected during prototyping?

Buyers should establish NDAs prior to file submission. Top-tier suppliers implement internal data access controls and may offer encrypted file transfer channels. Avoid sharing unpatented designs without legal safeguards.