Prototype Machine Shops

About prototype machine shops

Where to Find Prototype Machine Shops?

China serves as a central hub for prototype machine shop services, with key manufacturing clusters in Zhejiang, Guangdong, and Anhui provinces. These regions host vertically integrated facilities specializing in rapid prototyping, CNC machining, 3D printing, and PCB assembly. Zhejiang excels in automated electronics production equipment, offering turnkey solutions for PCB prototyping machines with full supply chain integration. Guangdong's Dongguan and Guangzhou zones are renowned for high-mix, low-volume prototyping services, leveraging dense networks of material suppliers and logistics providers to reduce lead times by up to 40% compared to Western counterparts.

The industrial ecosystems support both component-level manufacturing and end-to-end prototyping workflows. Suppliers benefit from localized access to precision tooling, metrology labs, and automation engineers within 50km radii, enabling rapid iteration cycles. Buyers can expect standard lead times of 7–15 days for custom prototypes, with production costs 20–35% lower than domestic alternatives due to efficient labor allocation and streamlined material sourcing. This infrastructure supports scalable output—from one-off samples to pilot runs—while maintaining tight tolerances and repeatability.

How to Choose Prototype Machine Shops?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in relevant prototyping methods: CNC milling, vacuum casting, SLA/SLS 3D printing, or pick-and-place automation. For hardware startups and R&D teams, assess compatibility with materials such as ABS, nylon, resin, aluminum, and stainless steel. Prioritize shops that document process validation through first-article inspections and dimensional reports. ISO 9001 certification indicates adherence to quality management standards, though not universally held among specialized micro-factories.

Production Infrastructure Assessment

Evaluate scalability indicators:

- Minimum facility size of 1,000m² for multi-process operations

- In-house capabilities spanning design, machining, molding, and surface finishing

- Dedicated engineering teams supporting DFM feedback and iterative revisions

Cross-reference on-time delivery rates (target ≥95%) and response times (ideally ≤4 hours) to gauge operational responsiveness.

Transaction Risk Mitigation

Utilize secure payment mechanisms where possible, especially for initial engagements. Review reorder rates as a proxy for customer satisfaction—shops exceeding 50% indicate strong service consistency. Request sample parts to validate surface finish, accuracy, and assembly fit before committing to volume work. Clarify IP protection policies when sharing sensitive designs.

What Are the Best Prototype Machine Shops?

| Company Name | Location | Online Revenue | Main Services | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

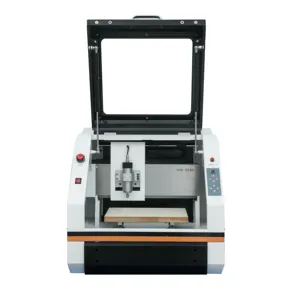

| Zhejiang Neoden Technology Co., Ltd. | Zhejiang, CN | US $170,000+ | PCB Pick-and-Place Machines | 96% | ≤3h | <15% | Yes | 1 set |

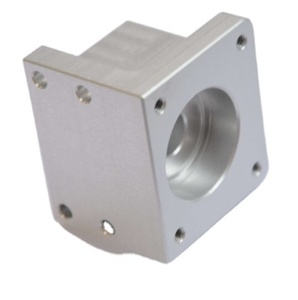

| Dongguan Yyi Technology Co., Ltd. | Guangdong, CN | US $30,000+ | Plastic Prototyping, SLA/SLS | 100% | ≤3h | 53% | Yes | 1 piece |

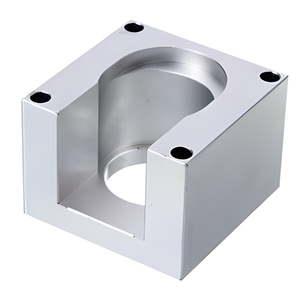

| Anqing Wayne Hand Model Technology Co., Ltd. | Anhui, CN | US $220,000+ | CNC, Vacuum Casting, Metal 3D Printing | 92% | ≤1h | 46% | Yes | 1 piece |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangdong, CN | US $30,000+ | Rapid Prototyping, CNC Machining | 100% | ≤4h | 68% | Yes | 1 unit |

| Wuxi Huawen Machinery And Electronics Co., Ltd. | Jiangsu, CN | - | PCB Prototyping Equipment | 100% | ≤8h | - | Limited | 1–100 sets |

Performance Analysis

Zhejiang Neoden stands out for automated PCB prototyping systems, offering fully integrated pick-and-place machines priced from $2,899 to $19,999 per set. Despite a low reorder rate, its high customization capacity and established production line make it suitable for electronics manufacturers scaling in-house prototyping. Dongguan Yyi and Guangzhou Gaojie specialize in low-cost plastic prototypes with MOQs starting at one piece, ideal for product designers validating form and function. Anqing Wayne Hand leads in technical breadth, providing metal 3D printing (SLM), urethane casting, and high-precision CNC services at competitive unit prices below $5. Wuxi Huawen focuses on capital equipment for PCB development but offers limited flexibility in order volume, requiring bulk commitments for optimal pricing.

FAQs

How to verify prototype machine shop reliability?

Validate performance metrics such as on-time delivery and response time through platform-verified transaction histories. Request evidence of in-house production equipment via facility photos or video tours. Assess technical competence by reviewing service listings across machining, molding, and additive processes.

What is the typical sampling timeline for prototypes?

Standard CNC or 3D printed prototypes are delivered within 3–7 days. Complex assemblies or metal AM parts may require 10–14 days. PCB machine suppliers typically ship complete systems within 15–25 days after order confirmation.

Can prototype shops handle global shipping?

Yes, most suppliers offer international logistics via air freight or sea container. Confirm Incoterm preferences (FOB, CIF) and ensure packaging meets export standards for sensitive electronic equipment or fragile models.

Do suppliers provide free samples?

Free samples are uncommon for machined or printed parts due to material and setup costs. Some vendors offer discounted first-run pricing or waive fees upon conversion to production orders.

How to initiate customization requests?

Submit detailed specifications including CAD files, material requirements, tolerance levels, and finish preferences. Leading shops provide DFM analysis within 24–48 hours and support iterative revisions to optimize manufacturability and cost efficiency.