Prototyping And Low Volume Production

About prototyping and low volume production

Where to Find Prototyping and Low Volume Production Suppliers?

China remains a global hub for prototyping and low-volume production services, with specialized manufacturing clusters concentrated in Shenzhen, Dongguan, and Anqing. These regions host vertically integrated workshops equipped with advanced CNC machining centers, 3D metal printing systems, and vacuum casting lines. Shenzhen stands out as a technology-driven prototyping center, offering rapid turnaround times due to its dense network of material suppliers, post-processing facilities, and logistics providers operating within a 50km radius.

The ecosystem supports agile development cycles, enabling same-day quoting and prototype delivery within 24–72 hours for urgent projects. Suppliers leverage economies of scale through shared tooling infrastructure and standardized workflows, reducing per-unit costs by up to 40% compared to Western counterparts. Buyers benefit from flexible MOQs starting at one piece, access to multi-material processing (including ABS, PC, nylon, aluminum, and stainless steel), and seamless transition from concept validation to small-batch manufacturing.

How to Choose Prototyping and Low Volume Production Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities Verification

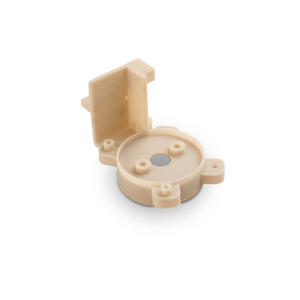

Confirm availability of core technologies: CNC machining (3-axis to 6-axis), industrial 3D printing (SLS, DMLS, SLA), urethane casting, and sheet metal fabrication. Prioritize suppliers with documented experience in precision tolerances (±0.05mm) and surface finishing options (anodizing, polishing, painting). For metal components, verify use of certified alloys and heat treatment processes.

Quality Management Systems

While formal ISO 9001 certification is not universally listed, consistent on-time delivery rates above 95% and reorder rates exceeding 40% indicate robust internal quality controls. Evaluate response time metrics—suppliers responding within ≤2 hours demonstrate operational readiness. Cross-reference claimed capabilities with actual product listings, focusing on diversity and specificity of service offerings.

Production Scalability & Customization

Assess customization depth:

- Support for CAD/STL file submissions

- Material selection across plastics, metals, and composites

- Finishing and labeling options (color matching, engraving, packaging)

- Tooling support for vacuum casting and rapid molds

Suppliers with over 1,000 active listings in machining or molding suggest high throughput capacity and process maturity.

Transaction Risk Mitigation

Analyze online revenue indicators and repeat order performance as proxies for reliability. Favor suppliers with transparent pricing structures, clear minimum order definitions, and documented revision policies. Request sample prototypes before committing to volume runs to validate dimensional accuracy and finish quality.

What Are the Best Prototyping and Low Volume Production Suppliers?

| Company Name | Main Services | Listing Volume | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Anqing Wayne Hand Model Technology Co., Ltd. | Machining, Casting, 3D Printing | 1,421+ listings | 92% | 47% | ≤2h | $240,000+ | 1 pc | $3.89–$10.70 |

| Shenzhen Yuhan Precision Technology Co., Ltd. | Vacuum Casting, Machining, Low-Volume Molding | Multiple Customization Options | 100% | 50% | ≤1h | $20,000+ | 1 pc | $1–$40 |

| Dongguan Best Precision Hardware Products Co., Ltd. | CNC Machining, SLS 3D Printing | 3,947+ listings | 100% | 31% | ≤2h | $110,000+ | 10–100 pcs | $2–$18 |

| Shenzhen GH Prototype Technology Co., Ltd | Low-Volume Plastic, HD 3D Printing | 713+ listings | 100% | 50% | ≤2h | $10,000+ | 1–2 pcs | $0.11–$6.66 |

| Shenzhen Kaier Wo Prototyping Technology Co., Ltd. | CNC, Vacuum Casting, Silicone Molding | Customization Supported | 100% | 40% | ≤2h | $900,000+ | 1 pc | $1–$15 |

Performance Analysis

Shenzhen-based suppliers dominate responsiveness and customization breadth, with three achieving 100% on-time delivery and sub-2-hour average response times. Anqing Wayne Hand and Dongguan Best exhibit strong production scalability, evidenced by high listing volumes in machining and metal fabrication. Kaier Wo leads in commercial traction with over $900,000 in reported online revenue, suggesting extensive client engagement in OEM and custom prototyping. Cost leaders like Shenzhen GH offer entry-level pricing below $0.15/unit for basic plastic parts, ideal for early-stage testing. For complex metal prototypes, DMLS and precision CNC services range from $4.70–$18.00/unit with batch flexibility.

FAQs

How to verify prototyping supplier capability?

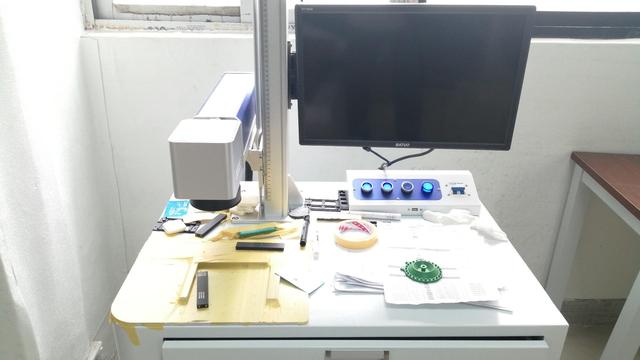

Request facility videos showcasing CNC machines, 3D printers, and inspection equipment. Validate technical proficiency by submitting a test design file and evaluating quote accuracy, suggested materials, and tolerance annotations. Check consistency between listed services and actual product descriptions.

What is the typical lead time for prototypes?

Standard CNC or 3D printed prototypes are delivered in 1–5 days. Vacuum casted parts with mold creation require 5–7 days. Expedited 24-hour services are available for simple geometries in select suppliers.

Do suppliers support full production scaling?

Yes, many offer seamless transition from prototype to low-volume batches (100–1,000 units) using the same tooling and QC protocols. Confirm scalability by reviewing past orders and asking about change management procedures for design iterations.

Are samples available before bulk orders?

Most suppliers provide initial prototypes as functional samples. Pricing typically applies, but may be credited toward subsequent production runs. Expect 1–3 rounds of revisions for optimal fit and function.

What file formats do manufacturers accept?

Standard formats include STEP, IGES, STL, and DWG for 3D models. Suppliers also accept hand sketches or PDF drawings for basic components. High-resolution files improve quoting accuracy and reduce interpretation errors.