Prototyping In Additive Manufacturing

CN

CN

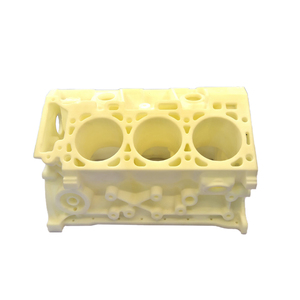

About prototyping in additive manufacturing

Where to Find Prototyping in Additive Manufacturing Suppliers?

China leads global production capacity for prototyping in additive manufacturing, with concentrated supplier hubs in Guangdong, Shanghai, and Shandong provinces. These regions host vertically integrated facilities combining design engineering, rapid tooling, and multi-material 3D printing capabilities. Guangdong alone accounts for over 45% of China’s industrial additive manufacturing output, supported by mature ecosystems linking polymer and metal printing specialists with post-processing and quality control services within 30km radii.

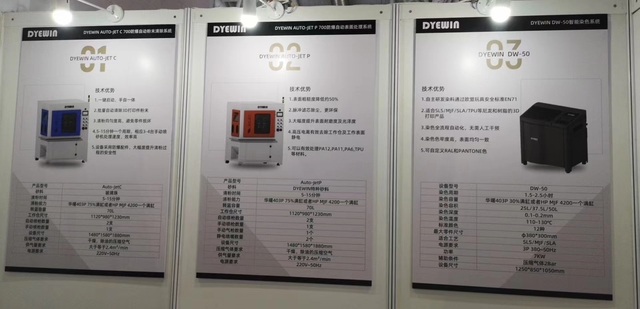

Suppliers in these clusters leverage localized access to raw materials—such as PA12, ABS, aluminum alloys (AlSi10Mg), stainless steel, and high-toughness resins—to reduce material lead times by up to 40%. Integrated CNC machining, SLM (Selective Laser Melting), SLS (Selective Laser Sintering), and SLA (Stereolithography) lines enable end-to-end prototyping from digital models to functional test units. Buyers benefit from scalable production footprints, with average facility sizes exceeding 3,000m² and monthly capacities ranging from hundreds to tens of thousands of prototype units depending on complexity.

How to Choose Prototyping in Additive Manufacturing Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm access to required printing technologies: SLS for nylon-based functional prototypes, SLA for high-detail resin parts, and SLM/DMLS for metal components. Validate compatibility with industry-standard file formats (STL, STEP) and support for common engineering materials including TPU, PA, AlSi7Mg, and 316L stainless steel. Request proof of build volume specifications and layer resolution (typically 20–100μm).

Production & Quality Assurance

Assess infrastructure maturity through the following criteria:

- In-house R&D or design validation teams

- Integration of post-processing capabilities (heat treatment, painting, bonding, chrome plating)

- Documented QC procedures for dimensional accuracy (±0.1–0.3mm tolerance)

- On-time delivery performance ≥98%

While ISO 9001 certification is not universally listed, suppliers with consistent reorder rates (>30%) and sub-5-hour response times demonstrate operational reliability. Prioritize partners offering sample prototypes before full-scale production.

Procurement Risk Mitigation

Utilize secure payment frameworks where funds are released only after product inspection. Evaluate online transaction history indicators such as verified revenue tiers and dispute resolution records. Conduct video audits to verify equipment ownership and workforce expertise, especially when outsourcing complex multi-material assemblies or mission-critical metal prototypes.

What Are the Best Prototyping in Additive Manufacturing Suppliers?

| Company Name | Location | Main Materials | Processing Techniques | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Pulesheng Technology (Guangdong) Co., Ltd. | Guangdong, CN | Metal, Resin | Laser Printing, Metal 3D Printing | 100% | ≤9h | Not specified | US $100+ | 2–50 pieces |

| Shanghai Yunyan Prototype And Mould Manufacture Factory | Shanghai, CN | Nylon, Aluminum, Stainless Steel | SLM, SLS, Electroplating, Painting | 100% | ≤3h | 35% | US $60,000+ | 1 piece |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangdong, CN | Plastic, Resin | CNC Machining, SLS, SLA, 3D Layered Printing | 100% | ≤5h | 80% | US $30,000+ | 1 unit |

| Shenzhen Heruiyun Technology Co., Ltd. | Guangdong, CN | Nylon, Plastic, High-Toughness Resin | SLA, SLS, OEM/ODM Tooling | 100% | ≤1h | 27% | US $7,000+ | 10 pieces |

| HUITONG RAPID PROTOTYPE & SUPPLY COMPANY LIMITED | Guangdong, CN | ABS, Nylon, Metal, Resin | SLM, SLS, SLA, Artistic Fabrication | 100% | ≤3h | 20% | US $30,000+ | 1 piece |

Performance Analysis

Guangzhou Gaojie stands out with an 80% reorder rate, indicating strong client retention likely driven by responsive service and diversified processing options. Shanghai Yunyan offers the lowest MOQs (1 piece) and broad customization scope—including electroplating, color finishing, and STL file optimization—making it ideal for low-volume, high-complexity projects. Shenzhen Heruiyun leads in responsiveness (≤1h average reply time) but has a lower reorder rate, suggesting potential gaps in long-term satisfaction despite technical agility. Pulesheng and Huitong provide competitive pricing structures ($0.90–$2.50 range) suitable for medium-batch functional testing. All five suppliers maintain perfect on-time delivery records, underscoring reliable logistics execution across the sector.

FAQs

What materials are commonly used in additive manufacturing prototyping?

Standard materials include nylon (PA12) for durable functional prototypes, ABS and TPU for flexible or impact-resistant parts, photopolymer resins for high-resolution visual models, and metal powders like AlSi10Mg, AlSi7Mg, and 316L stainless steel for industrial-grade metal components.

What is the typical lead time for prototype samples?

Simple plastic prototypes take 3–7 days; complex metal prints using SLM may require 10–15 days including post-processing. Shipping adds 5–10 days via express courier. Expedited services are available at select suppliers for urgent requests.

Can suppliers handle custom designs and file preparation?

Yes, most suppliers accept STL, STEP, and IGES files and offer free design validation. Some provide reverse engineering or CAD reconstruction from sketches or physical samples, particularly those advertising customization options like labeling, logo integration, and surface treatments.

What are standard MOQs and pricing ranges?

MOQs vary from 1 piece (common in Shanghai and Guangdong) to 10–50 pieces for filament or batch-processed items. Unit prices typically range from $0.20 to $15, depending on material, geometry complexity, and finishing requirements.

Do suppliers support global shipping and compliance documentation?

Yes, all listed suppliers have international transaction experience. While formal certifications (e.g., ISO, CE) are not explicitly stated, their participation in structured trade platforms indicates adherence to baseline export protocols. Buyers should request material test reports and RoHS compliance statements for regulated industries.