Push Fitting Producer

About push fitting producer

Where to Find Push Fitting Producers?

China remains the global hub for push fitting manufacturing, with key production clusters concentrated in Guangdong, Zhejiang, and Jiangsu provinces. Dongguan and Wenzhou serve as primary industrial centers, hosting vertically integrated facilities that specialize in pneumatic and plumbing components. These regions benefit from mature supply chains for brass, stainless steel, and engineering plastics, enabling cost efficiencies of 20–35% compared to European or North American producers.

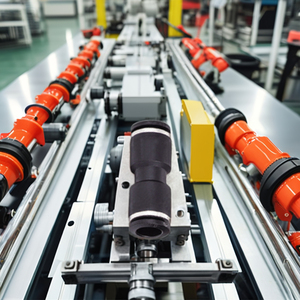

Suppliers in these zones operate dedicated production lines for push fittings, supported by localized tooling, molding, and surface treatment services within a 50km radius. This integration reduces component lead times and supports rapid prototyping. Average monthly output across verified manufacturers ranges from 500,000 to over 2 million units, depending on material complexity and order specifications. Buyers gain access to scalable production capable of fulfilling both bulk orders and low-volume custom configurations with typical lead times of 15–30 days.

How to Choose Push Fitting Producers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Production & Customization Capability

Prioritize manufacturers with in-house tooling and CNC machining capabilities to ensure design flexibility. Verified producers offer customization across thread types (NPT, BSP, metric), materials (brass, 304/316 stainless steel, nylon, polyurethane), color finishes, logo embossing, and packaging configurations. Suppliers advertising "own production line" typically maintain control over quality and delivery timelines.

Quality Assurance & Compliance

While formal ISO 9001 certification is not universally listed, top-tier producers demonstrate quality through consistent on-time delivery rates (≥97%) and documented process controls. For export markets, verify compliance with regional standards such as RoHS (EU) or NSF/ANSI 61 (plumbing applications in North America). Request test reports for pressure resistance (typically rated 1.0–2.0 MPa) and leak integrity under dynamic cycling conditions.

Order Flexibility & Transaction Metrics

Evaluate minimum order quantities (MOQs), which range from 1 piece for sample testing to 1,000 pieces for bulk pricing. Competitive pricing starts at $0.01/unit for basic plastic variants and exceeds $5.00 for specialty stainless steel configurations. Key performance indicators include:

- On-time delivery rate >97%

- Average response time ≤2 hours

- Reorder rate below 33% (indicating broad customer acquisition vs. dependency)

- Online transaction volume exceeding US $60,000 annually

Cross-reference these metrics with customization scope and material certifications to assess supplier reliability.

What Are the Best Push Fitting Producers?

| Company Name | Location | Verified Type | Main Materials | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|---|

| Dongguan Yuedu Mould Hardware Co., Ltd. | Guangdong, CN | Custom Manufacturer | Brass, Stainless Steel, Plastic | $0.10–$0.99 | 100–1,000 pcs | 100% | ≤1h | <15% | Color, material, size, logo, thread, packaging |

| Wenzhou Bgt Electric & Pneumatic Solution Co., Ltd. | Zhejiang, CN | - | PU, PE, Brass | $0.12–$0.42 | 100 pcs | 100% | ≤2h | <15% | Limited (main product focus) |

| Zhuji Kailun Hardware Products Co., Ltd. | Zhejiang, CN | - | Stainless Steel, Nylon, Plastic | $0.01–$58.00 | 1–100 pcs | 100% | ≤2h | <15% | Size, thread, material, packaging |

| Shanghai Ruan Long Industrial Automation Appliance Co., Ltd. | Shanghai, CN | Custom Manufacturer | Stainless Steel, Copper, Plastic | $0.31–$5.00 | 1–10 pcs | 98% | ≤3h | 33% | Thread type, color, logo, model, packaging |

| Ningbo Pneumatic Technical Expert Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Brass, Stainless Steel, Plastic | $0.13–$3.40 | 100 pcs | 97% | ≤3h | 23% | Color, material, size, logo, thread, packaging |

Performance Analysis

Dongguan Yuedu stands out with a 100% on-time delivery rate and sub-one-hour response time, coupled with extensive customization options and verified manufacturer status. Its competitive pricing and low reorder rate suggest strong market reach and consistent quality. Zhuji Kailun offers the lowest MOQs (down to 1 piece) and highly competitive pricing for plastic variants, making it ideal for sampling and niche applications. Shanghai Ruan Long provides broad material diversity but has a higher reorder rate (33%), indicating potential concentration in specific client segments. Ningbo Pneumatic Technical Expert demonstrates solid engineering depth with custom 3-way and check valve configurations, though response times are slower. Wenzhou Bgt focuses on standardized pneumatic solutions with stable delivery performance but limited customization scope.

FAQs

How to verify push fitting producer reliability?

Cross-check self-reported production claims with transaction volume, delivery consistency, and response efficiency. Request evidence of in-house tooling or facility operations via video audit. Analyze product listings for technical specificity—suppliers detailing thread standards, pressure ratings, and material grades are more likely to adhere to structured quality processes.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Custom designs requiring new molds may take 20–30 days. Air shipping adds 5–10 days for international delivery. Some suppliers offer free samples for qualified buyers committing to future volume orders.

Can push fitting producers ship globally?

Yes, most established manufacturers support international logistics via air or sea freight under FOB, CIF, or DDP terms. Confirm Incoterms, customs documentation, and import compliance (e.g., REACH, RoHS) before shipment. Full container loads (FCL) are recommended for orders exceeding 100,000 units to optimize freight costs.

Do suppliers accept small MOQs for new buyers?

Many producers allow trial orders as low as 1–100 pieces, especially for plastic or standard brass fittings. Higher-value stainless steel or custom-engineered models may require 500–1,000 unit minimums. Negotiate incremental scaling based on initial quality validation.

How to initiate customization requests?

Submit detailed specifications including tube outer diameter, thread type (metric/BSP/NPT), material grade, operating pressure, and environmental exposure (e.g., UV, chemical). Reputable manufacturers respond with dimensional drawings or CAD models within 48–72 hours and provide prototype samples within 2–4 weeks.