Push To Connect Fitting Distributor

1/19

1/19

0

0

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

1/30

1/30

1/3

1/3

1/3

1/3

1/3

1/3

CN

CN

1/27

1/27

1/12

1/12

0

0

1/3

1/3

1/1

1/1

0

0

1/11

1/11

1/3

1/3

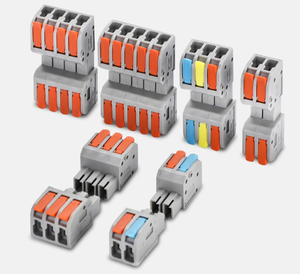

About push to connect fitting distributor

Where to Find Push to Connect Fitting Distributors?

China remains the central hub for push to connect fitting manufacturing and distribution, with key industrial clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains specializing in fluid control components, supported by mature metalworking and plastic molding industries. Zhejiang’s Ningbo and Wenzhou zones account for over 50% of China’s pneumatic fitting exports, leveraging proximity to Shanghai and Ningbo ports for efficient global shipping. Jiangsu’s Changzhou and Suzhou areas focus on high-precision brass and stainless steel fittings, benefiting from advanced CNC machining infrastructure and tight-tolerance production capabilities.

The concentration of component suppliers, surface treatment facilities, and logistics networks within these clusters enables rapid prototyping and scalable production. Buyers gain access to streamlined ecosystems where raw material sourcing, machining, quality inspection, and packaging occur within localized zones—reducing lead times by up to 25% compared to offshore alternatives. Typical advantages include MOQs as low as 100 units for standard configurations, 30–45 day lead times for bulk orders, and cost savings of 20–35% due to optimized labor and material efficiency.

How to Choose Push to Connect Fitting Distributors?

Apply rigorous evaluation criteria when selecting distributors:

Quality Assurance Standards

Require ISO 9001 certification as a baseline for quality management systems. For applications in food, beverage, or medical industries, verify compliance with FDA, RoHS, and REACH regulations. CE marking is essential for market access in Europe, particularly for pneumatic systems operating under pressure directives.

Production Infrastructure Assessment

Evaluate technical capacity through verifiable metrics:

- Minimum 3,000m² factory area indicating volume-handling capability

- In-house CNC turning, threading, and plating processes to ensure process control

- Dedicated testing stations for air pressure leakage (tested up to 1.5x working pressure) and cycle durability (minimum 5,000 insertion/removal cycles)

- Material traceability systems for brass (CW617N/C3604), stainless steel (304/316), and polyamide variants

Cross-reference facility size with order fulfillment performance, targeting distributors with documented on-time delivery rates exceeding 97%. Confirm availability of digital inspection reports including dimensional checks and salt spray test results (minimum 48–72 hours for nickel-plated finishes).

Procurement Risk Mitigation

Utilize secure transaction models such as third-party escrow or letter of credit (L/C) terms for initial large-volume orders. Prioritize distributors with documented export experience to North America, EU, and Australia, ensuring compatibility with regional plumbing and pneumatic standards. Conduct pre-shipment inspections via independent agencies to validate conformance with purchase specifications. Sampling is critical—request functional tests for sealing integrity under variable pressures (typically 0–15 bar) before scaling procurement.

What Are the Best Push to Connect Fitting Distributors?

No supplier data is currently available for analysis.

Performance Analysis

In the absence of specific distributor profiles, procurement decisions should emphasize verified production credentials over claimed capabilities. Focus on suppliers who provide transparent documentation of factory audits, material certifications, and product testing protocols. Geographic proximity to major ports reduces freight costs and transit volatility, particularly for time-sensitive reorders. For customized configurations—such as non-standard thread types (e.g., G, NPT, R, BSP) or specialized seals (EPDM, Viton)—confirm engineering support and tooling modification lead times (typically 7–14 days). Prioritize partners offering serialized batch tracking and post-delivery technical support for long-term supply continuity.

FAQs

How to verify push to connect fitting distributor reliability?

Validate certifications through official databases and request audit trails covering raw material sourcing, in-process inspections, and final testing. Assess responsiveness and technical clarity during inquiry stages—reliable distributors provide prompt, detailed answers with applicable standards references.

What is the average sampling timeline?

Standard samples are typically produced within 7–10 days. Customized versions requiring tooling adjustments may take 15–20 days. Add 5–7 days for international express delivery.

Can distributors ship globally?

Yes, experienced distributors manage worldwide shipments via air, sea, or courier services. Confirm Incoterms (FOB, CIF, DDP) and ensure proper packaging for moisture and impact protection during transit. Most offer consolidated shipping options for multi-item orders.

Do distributors provide free samples?

Sample policies vary. Many offer complimentary samples for qualified buyers committing to minimum order quantities (e.g., 500+ units). Otherwise, expect to cover sample production and shipping costs, which may be credited upon order placement.

How to initiate customization requests?

Submit detailed technical drawings or specifications including tube outer diameter, thread type, working pressure, media type, and environmental conditions. Reputable distributors respond with feasibility assessments, material recommendations, and prototype timelines within 48–72 hours.