Quick 3d Printing Service

Top sponsor listing

Top sponsor listing

1/31

1/31

1/21

1/21

1/24

1/24

1/18

1/18

1/30

1/30

About quick 3d printing service

Where to Find Quick 3D Printing Service Suppliers?

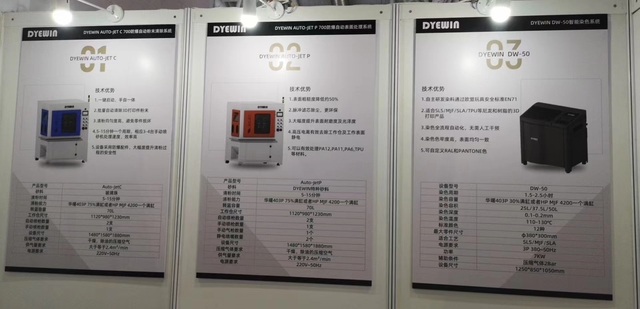

China leads global supply of rapid 3D printing services, with key manufacturing hubs concentrated in Guangdong and Guangzhou. These regions host vertically integrated prototyping and production ecosystems, combining advanced additive manufacturing infrastructure with streamlined logistics networks. Guangdong’s Shenzhen and Dongguan zones specialize in high-precision plastic and metal printing, supporting industries ranging from consumer electronics to medical devices.

The region's dominance stems from dense clusters of technical workshops, material suppliers, and post-processing facilities operating within tight geographic proximity—reducing coordination delays and enabling same-day order initiation. This integration allows lead times as fast as 2–5 days for standard prototypes, with express options available for urgent requests. Buyers benefit from scalable capacity, localized resin and filament sourcing, and access to multi-process capabilities including SLA, SLS, MJF, and SLM—all within a single sourcing region.

How to Choose Quick 3D Printing Service Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Production & Material Capabilities

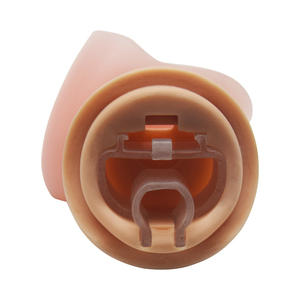

Confirm availability of required printing technologies: SLA for transparent resins, SLS/MJF for nylon-based functional parts, and SLM for metal alloys (titanium, aluminum, stainless steel). Evaluate material certifications—particularly for engineering-grade thermoplastics or biocompatible resins used in regulated sectors. Suppliers should offer surface finishing options such as polishing, painting, electroplating, and CNC trimming to meet end-use specifications.

Quality Assurance Systems

Prioritize partners demonstrating consistent quality control through documented processes. While formal ISO 9001 certification is not universally listed, on-time delivery rates exceeding 95% and response times under 6 hours serve as proxy indicators of operational discipline. Reorder rates above 30% suggest customer satisfaction with output consistency and service reliability.

Customization & Technical Support

Assess digital workflow compatibility: suppliers must support common file formats (STP, STL, 3D drawings) and provide design-for-manufacturability feedback. Strong candidates offer engraving, color matching, vacuum casting integration, and hybrid fabrication (e.g., combining 3D printing with CNC milling or sheet metal work). Rapid quoting within 4 hours indicates robust engineering bandwidth.

Transaction Reliability Indicators

Favor suppliers with verifiable online revenue exceeding US $20,000 annually, indicating sustained commercial activity. Use response time ≤5 hours and 100% on-time delivery records as benchmarks for responsiveness and execution capability. Escrow-backed transactions and sample validation remain critical before scaling orders.

What Are the Best Quick 3D Printing Service Suppliers?

| Company Name | Main Materials | Printing Technologies | MOQ | Price Range (USD) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Pulesheng Technology (Guangdong) Co., Ltd. | Resin, Plastic, Metal | SLA, SLS, SLM | 1 unit | $0.15–5.00 | 100.0% | ≤11h | - | US $100+ |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | UV Resin, Aluminum, Jewelry Alloys | SLA, SLS, SLM | 1 unit | $0.35–1.15 | 100.0% | ≤5h | 85% | US $30,000+ |

| Yongkang Teyifei Metal Technology Co., Ltd. | Steel, Aluminum, Titanium Alloy | SLM, Custom Metal Printing | 1 piece | $0.50–5.00 | 100.0% | ≤6h | 33% | US $20,000+ |

| Shenzhen Industrial Man Rapid Prototyping Manufacturing Co., Ltd. | ABS, Carbon Fiber, Nylon, Resin | Stereolithography, CNC Hybrid | 1 piece | $0.10–0.30 | 95.0% | ≤4h | 18% | US $130,000+ |

| Shenzhen VMT Metal Product Co., Ltd. | Nylon, ABS, Metal Alloys | MJF, SLM, SLA | 1 piece | $0.01–1.00 | 100.0% | ≤2h | 37% | US $190,000+ |

Performance Analysis

Shenzhen VMT stands out with the fastest average response time (≤2h) and highest reported online revenue (US $190,000+), indicating strong market presence and operational agility. Its competitive pricing—down to $0.01 per piece—reflects economies of scale in MJF nylon printing. Guangzhou Gaojie excels in reorder rate (85%), suggesting superior client retention likely driven by specialized jewelry and UV resin prototyping expertise. Pulesheng Technology offers broad material coverage but lacks reorder data, warranting further due diligence. Shenzhen Industrial Man provides the lowest base pricing ($0.10–0.30) and extensive customization options, though its 95% on-time delivery rate slightly trails top performers. Yongkang Teyifei focuses on high-value metal printing, positioning itself for industrial clients requiring titanium or steel components via SLM technology.

FAQs

How to verify quick 3D printing service supplier reliability?

Cross-check performance metrics such as on-time delivery and response time against historical transaction data. Request sample parts to evaluate dimensional accuracy, surface finish, and material properties. Verify technical alignment through STP file reviews and pre-production confirmations.

What is the typical lead time for rapid 3D printed prototypes?

Standard lead times range from 3 to 7 days, depending on complexity and finishing requirements. Express services can reduce turnaround to 24–48 hours for non-metal prints. Metal 3D printing (SLM) typically requires 5–10 days due to slower build rates and mandatory heat treatment cycles.

Do suppliers support small batch and custom orders?

Yes, all listed suppliers accept MOQs of 1 unit, catering to prototype development and low-volume production. Customization includes geometry, color, texture, and hybrid processing such as post-CNC machining or electroplating.

Are material certifications available for regulated industries?

Suppliers offering biocompatible resins or aerospace-grade metals should provide traceable material data sheets. For medical or automotive applications, request RoHS, REACH, or UL compliance documentation where applicable.

How are pricing and volume discounts structured?

Pricing is typically tiered by part volume, material type, and post-processing level. Significant reductions occur at 10+, 50+, and 100+ unit thresholds. Automated quoting systems allow instant price calculation based on uploaded 3D models.