Red Lamp Shade

Top sponsor listing

Top sponsor listing

1/4

1/4

1/20

1/20

About red lamp shade

Where to Find Red Lamp Shade Suppliers?

China remains the central hub for red lamp shade manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving global supply. Zhongshan, located in Guangdong, is renowned as a lighting industry base, hosting vertically integrated facilities that specialize in decorative lighting components including custom lamp shades. The region supports end-to-end production—from fabric cutting and metal stamping to final assembly—enabling rapid prototyping and scalable output. Zhejiang’s Haining and Ningbo areas complement this ecosystem with expertise in textile-based shades and industrial-style metal diffusers, offering diverse material options such as linen, velvet, silicone, and brass.

These industrial zones benefit from concentrated supplier networks, reducing component sourcing lead times by 20–30%. Manufacturers typically operate semi-automated production lines capable of monthly outputs ranging from 10,000 to 50,000 units depending on complexity. This infrastructure allows for competitive pricing, with standard red lamp shades produced at $4.50–$13.50 per unit for orders exceeding 100 pieces. Buyers gain access to flexible MOQs, short lead times (15–30 days), and strong customization capabilities across colorfastness, dimensional tolerances, and electrical compatibility.

How to Choose Red Lamp Shade Suppliers?

Effective supplier selection requires structured evaluation based on operational performance and technical capability:

Quality & Compliance Verification

Confirm adherence to international standards such as RoHS for hazardous substance control and CE marking for electrical safety where applicable. While formal ISO 9001 certification is not universally documented among listed suppliers, prioritize those demonstrating consistent on-time delivery rates above 95% and verifiable quality control processes. Evaluate material specifications—particularly for flame-retardant fabrics and UL-listed wiring—to ensure compliance with destination market regulations.

Production Capacity Assessment

Key indicators of scalability include:

- Facility size supporting batch production of 5,000+ units monthly

- In-house design teams enabling shape, size, and graphic customization

- Integrated molding, sewing, and metalworking capabilities

Cross-reference response time data (e.g., ≤2h vs. ≤11h) with reorder rates to assess service reliability and customer satisfaction.

Transaction Risk Mitigation

Utilize secure payment terms such as escrow or letter of credit for initial orders. Request physical or digital samples before full-scale procurement to verify color accuracy, material texture, and structural integrity. Analyze online transaction histories where available, focusing on repeat order rates (target >20%) and fulfillment consistency. For customized designs, confirm tooling ownership and labeling rights in contractual agreements.

What Are the Best Red Lamp Shade Suppliers?

| Company Name | Type | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Revenue Tier | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Zhongshan Chuse Lighting Co., Ltd. | Custom Manufacturer | Table Lamps, Floor Lamps, Chandeliers, Smart Lights | 100% | 22% | ≤2h | US $130,000+ | Color, shape, size, logo, packaging, material | 50–200 pcs |

| Huizhou Jixin Lampshade Factory | Manufacturer | Lamp Covers & Shades, Pendant Lights | 100% | 25% | ≤11h | US $2,000+ | Linen, metal, velvet drum shades; fringe detailing | 100–200 pcs |

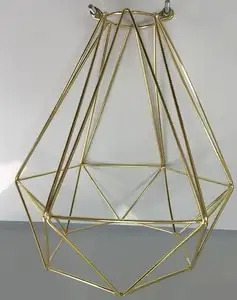

| Ningbo Yinzhou Qingyu Optoelectronics | Partnership | Industrial Lamp Shades, Wire Cages, Bulb Guards | 100% | 16% | ≤2h | US $8,000+ | Metal cage designs, foldable silicone shades | 5–100 pcs |

| Haining Eperson Import&Export Co., Ltd. | Trading/Manufacturing Hybrid | Floor Lamps, Table Lamps, Artistic Designs | 25% | 16% | ≤5h | US $10,000+ | Red glass, chrome arch, artistic forms | 2 pcs |

| CHINA LAMPS MANUFACTURER LIMITED | Manufacturer | Floor Lamps, Linen Shades, Standing Lamps | 50% | 20% | ≤6h | US $2,000+ | Modern brass and linen configurations | 50 pcs |

Performance Analysis

Zhongshan Chuse Lighting stands out with 100% on-time delivery, sub-2-hour response times, and high customization breadth, supported by significant revenue volume indicating scale. Huizhou Jixin Lampshade Factory matches delivery reliability and leads in reorder rate (25%), suggesting strong product consistency despite lower digital engagement speed. Ningbo Yinzhou Qingyu excels in niche industrial designs with ultra-low MOQs starting at 5 pieces, ideal for specialty buyers. In contrast, Haining Eperson offers the lowest MOQ (2 pieces) but reports only 25% on-time fulfillment, signaling potential logistical risks. CHINA LAMPS MANUFACTURER LIMITED shows moderate performance with balanced reorder metrics but lacks responsiveness compared to top-tier suppliers.

FAQs

How to verify red lamp shade supplier reliability?

Assess on-time delivery records, reorder rates, and response times as proxies for operational stability. Request sample batches to evaluate color consistency (especially for wine red or burgundy tones), material durability, and finish quality. Confirm whether suppliers manage production in-house or act as intermediaries.

What is the typical lead time for red lamp shade orders?

Standard orders require 15–25 days from confirmation, depending on material availability and finishing processes. Custom tooling or handcrafted elements (e.g., pleated linen, velvet brushing) may extend timelines to 35 days. Air freight adds 7–10 days for international delivery.

Can suppliers provide custom red lamp shades?

Yes, most manufacturers support full customization including diameter (20–60cm common range), height, fabric type (linen, cotton, polyester blends), and mounting mechanisms (spider, uno, clip-on). Some offer OEM branding via printed labels, engraved logos, or tailored packaging.

What are common materials used in red lamp shades?

Polyester and linen fabrics dominate soft shades for color vibrancy and diffusion properties. Velvet provides a premium matte finish with enhanced light absorption. Metal (iron, brass) and glass are used for industrial or modern designs, while silicone enables collapsible, impact-resistant variants.

Are there minimum order requirements?

MOQs vary widely: mass-produced models require 50–200 units, whereas specialty items like metal cages or hand-sewn textiles may start at 5–10 sets. Sample orders are often accepted at 1–2 pieces, typically priced 30–50% higher than bulk rates.