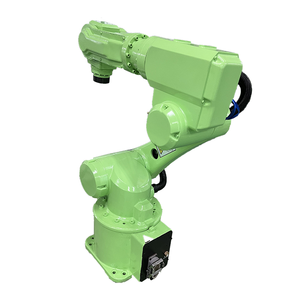

Robot Arm 6 Axis Distributor

Top sponsor listing

Top sponsor listing

0

0

1/36

1/36

CN

CN

1/36

1/36

1/11

1/11

1/11

1/11

CN

CN

1/7

1/7

1/5

1/5

1/3

1/3

0

0

1/14

1/14

0

0

1/7

1/7

1/28

1/28

1/3

1/3

1/3

1/3

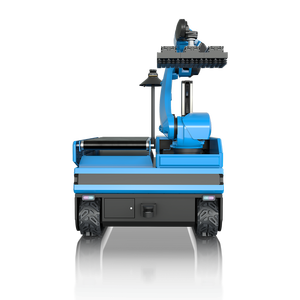

About robot arm 6 axis distributor

Where to Find 6-Axis Robot Arm Distributors?

China remains the central hub for 6-axis robot arm manufacturing and distribution, with key supplier clusters in Shanghai, Shenzhen, and Jiangsu offering distinct competitive advantages. These regions host vertically integrated automation ecosystems that combine precision engineering, robotics R&D, and advanced material handling systems. Shanghai-based suppliers benefit from proximity to major ports and industrial OEMs, enabling rapid deployment for export orders. Shenzhen’s innovation-driven environment supports agile production of collaborative robots (cobots), while Jiangsu integrates intelligent manufacturing research with commercial-scale output.

Suppliers in these zones operate within mature supply chains that include CNC machining, servo motor integration, and control system assembly—all within localized networks. This infrastructure reduces lead times to 30–45 days for standard configurations and supports cost efficiencies of 20–35% compared to Western or Southeast Asian alternatives. Buyers gain access to scalable production capacities, customization flexibility, and technical support for integration into automated workflows across industries such as electronics assembly, welding, packaging, and logistics.

How to Choose 6-Axis Robot Arm Distributors?

Selecting a reliable distributor requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capability & Compliance

Verify adherence to international standards including ISO 9001 for quality management and CE marking for safety compliance—essential for European market entry. For applications involving human-robot collaboration, ensure robots meet ISO/TS 15066 for cobot safety. Request documentation on repeatability (typically ±0.02mm to ±0.05mm), payload capacity (ranging from 3kg to 20kg across models), and controller compatibility (e.g., ROS, PLC, HMI integration).

Production and Customization Capacity

Assess supplier capabilities through the following indicators:

- In-house engineering teams capable of modifying arm length, gripper type, color, material, or software interface (SDK/API availability)

- Integration services for vision systems, laser welding, vacuum suction tools, or automated workstations

- Minimum order quantity (MOQ) policies: Most suppliers require only 1 set/unit, facilitating prototyping and small-scale deployment

- Custom branding options including logo printing, packaging design, and label configuration

Cross-reference product listings with verified performance metrics such as on-time delivery rates (>97% recommended) and response times (≤6 hours preferred) to assess reliability.

Transaction Security & After-Sales Support

Prioritize suppliers offering secure payment mechanisms and post-purchase safeguards. Evaluate reorder rates as an indicator of customer satisfaction—rates above 30% suggest consistent quality and service. Confirm availability of technical documentation, remote troubleshooting support, and spare parts supply chains. On-site installation or training may be available upon request, particularly for high-value units.

What Are the Leading 6-Axis Robot Arm Distributors?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response Time | Customization Options | Verification Status |

|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Conveyors, Cargo & Storage Equipment, Manipulator, Weighing Scales, Material Handling Equipment | US $60,000+ | 100% | 100% | ≤5h | Automation specifications, colors | Multispecialty Supplier |

| Shanghai Xuanyang International Trade Co., Ltd. | Collaborative Robots, Articulated Robots, Welding Equipment, Industrial Robots | US $7,000+ | 100% | <15% | ≤6h | None listed | - |

| Shenzhen Muma Automation Technology Co., Ltd. | Mini Cobot, Welding Robot, Collaborative Robot, PLC/HMI Systems | US $310,000+ | 100% | 36% | ≤2h | Color, material, size, logo, gripper, packaging, graphic design | Multispecialty Supplier |

| Jiangsu Jitri Intelligent Manufacturing Technology Institute Co., Ltd. | High-Precision Robotic Arms, Barista Robots, Automated Workstations | US $90,000+ | 100% | 50% | ≤6h | Laser integration, vision systems, payload design, SDK/API, welding layout, material selection | Multispecialty Supplier |

| Changzhou Heavth Science & Technology Co., Ltd. | Economical 6-Axis Robots, Programmable Industrial Arms, AI-Enabled Models | US $140,000+ | 100% | 32% | ≤3h | Arm length, gripper types, load weight, material, laser welding, model styling | Custom Manufacturer |

Performance Analysis

Senad Robot stands out with a 100% reorder rate, indicating exceptional buyer retention, likely driven by consistent delivery and responsive service. Shenzhen Muma leads in customization breadth and online revenue volume, suggesting strong market penetration in niche automation segments. Jiangsu Jitri demonstrates robust technical versatility, supporting complex integrations like ROS control and laser welding systems. Changzhou Heavth offers competitively priced models starting below $5,000, making it a viable option for budget-conscious buyers seeking programmable arms with moderate customization. Shanghai Xuanyang, while maintaining perfect on-time delivery, has a low reorder rate, which may reflect limited after-sales engagement or less differentiated offerings.

FAQs

What is the typical price range for 6-axis robot arms?

Prices vary significantly based on payload, precision, and features. Entry-level educational or mini-cobots start at $4,500–$7,500. Industrial-grade articulated arms range from $8,000 to $20,000, while specialized units (e.g., KUKA-based or fully automated barista systems) can exceed $26,000.

Do distributors offer customization?

Yes, most leading suppliers provide extensive customization, including mechanical modifications (arm length, gripper type), aesthetic changes (color, branding), and technical enhancements (vision systems, laser welders, SDK access). Custom programming and workstation integration are also available upon request.

What are common MOQ and lead time expectations?

Minimum Order Quantity is typically 1 unit, allowing for sample testing and pilot deployments. Lead times average 30–45 days for standard models; custom builds may extend to 60 days depending on complexity.

How can I verify a supplier’s credibility?

Check on-time delivery performance, reorder rate, and response time metrics. Request evidence of certifications (ISO, CE), facility videos, and customer references. Use secure transaction platforms where possible, especially for initial purchases.

Can robot arms be integrated into existing production lines?

Yes, many suppliers offer compatibility with PLCs, HMIs, and ROS environments. Integration support includes technical documentation, communication protocols, and optional programming assistance to synchronize with conveyors, sensors, and other machinery.