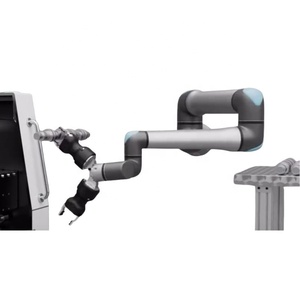

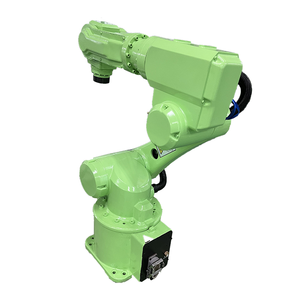

Robotic Arm 6 Axis Distributor

1/20

1/20

CN

CN

1/26

1/26

1/14

1/14

1/11

1/11

1/5

1/5

1/11

1/11

1/28

1/28

1/24

1/24

1/21

1/21

1/14

1/14

CN

CN

1/12

1/12

About robotic arm 6 axis distributor

Where to Find Robotic Arm 6 Axis Distributor Suppliers?

China remains the global epicenter for industrial robotics manufacturing, with key supplier clusters concentrated in Jiangsu, Shanghai, and Guangdong provinces. These regions host vertically integrated ecosystems combining R&D centers, component fabrication, and final assembly under one supply chain. Jiangsu and Shanghai lead in precision engineering for 6-axis articulated robots, leveraging proximity to Tier-1 automation research institutes and semiconductor hubs. Guangdong’s Shenzhen zone specializes in compact and collaborative models, supported by dense electronics networks enabling rapid prototyping and integration of vision systems, grippers, and control SDKs.

Suppliers in these zones benefit from localized access to servo motors, harmonic drives, and CNC-machined structural components, reducing material lead times by 20–35% compared to offshore production. The average facility operates on a 3,000–10,000m² footprint with monthly output capacity ranging from 50 to 300 units per line. Buyers gain flexibility in both standard and customized configurations, with typical delivery windows of 30–60 days depending on technical complexity. Cost advantages are significant—up to 40% lower than equivalent European or North American-built units—making these clusters ideal for cost-sensitive yet technically demanding deployments.

How to Choose Robotic Arm 6 Axis Distributor Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Confirm adherence to international quality benchmarks such as ISO 9001. For deployment in regulated environments (e.g., automotive, food processing), verify CE marking and functional safety compliance (ISO 13849). Demand documentation for repeatability testing (±0.02mm to ±0.05mm standard), payload validation, and cycle life endurance reports. Suppliers offering API/SDK integration should provide sample code libraries and communication protocols (Modbus, EtherCAT, PROFINET).

Production & Customization Capability

Assess infrastructure maturity through verifiable metrics:

- Facility size exceeding 3,000m² indicating scalable production

- In-house engineering teams capable of modifying reach, payload, or mounting configurations

- Integration capabilities for end-of-arm tooling (EOAT), laser welding, suction systems, or AI-driven vision modules

Cross-reference online revenue data and reorder rates: suppliers with reorder rates above 30% often deliver superior post-sale support and system reliability.

Transaction Security & Lead Time Management

Prioritize suppliers with documented on-time delivery performance (target ≥93%) and response times under 7 hours. Utilize secure payment mechanisms such as trade assurance or escrow services until site acceptance testing is completed. Request physical or digital samples before full-scale orders—especially for custom integrations—to validate kinematic accuracy and software compatibility.

What Are the Best Robotic Arm 6 Axis Distributor Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Verified Type |

|---|---|---|---|---|---|---|---|

| Shanghai Xuanyang International Trade Co., Ltd. | Shanghai, CN | Articulated Robots, Collaborative Robots, Welding Equipment | US $7,000+ | 100% | ≤7h | <15% | |

| Wuhan Questt Asia Technology Co., Ltd. | Hubei, CN | 6-Axis CNC Manipulators, EPSON-Compatible Arms | US $470,000+ | 88% | ≤5h | 35% | Custom Manufacturer |

| Jiangsu Jitri Intelligent Manufacturing Technology Institute Co., Ltd. | Jiangsu, CN | Cobots, Vision-Integrated Harvesting Robots, Servo Systems | US $90,000+ | 100% | ≤6h | 100% | Multispecialty Supplier |

| Robot Anno (Shenzhen) Co., Ltd. | Guangdong, CN | Vending Machines, Soldering Robots, 3D Printers | US $560,000+ | 100% | ≤4h | 18% | |

| Shenzhen Tianzhongtian Trading Co., Ltd. | Guangdong, CN | AR-Series Educational and Light Industrial Arms | US $400,000+ | 93% | ≤3h | <15% | Multispecialty Supplier |

Performance Analysis

Jiangsu Jitri stands out with a 100% reorder rate, indicating high customer retention likely driven by extensive customization options including vision systems, vacuum grippers, and application-specific programming. Wuhan Questt Asia demonstrates strong market penetration with mid-range precision arms priced between $15,800–$16,900, supported by robust after-sales engagement. Shenzhen-based Robot Anno offers diversified applications—from barista robots to industrial soldering—with the fastest average response time (≤4h) and highest online revenue, reflecting strong digital sales execution. Shanghai Xuanyang and Shenzhen Tianzhongtian focus on entry-level educational and light-duty units, with pricing as low as $79 for basic kits, catering to academic and prototyping use cases. Buyers seeking high-volume industrial deployment should prioritize suppliers with proven track records in automation integration and documented delivery consistency.

FAQs

What certifications should robotic arm suppliers have?

Essential certifications include ISO 9001 for quality management. For export to Europe, CE marking is mandatory. Optional but valuable standards include RoHS compliance for material safety and ISO 10218 for robot system safety. Always request test reports for electrical components, EMI shielding, and mechanical stress cycles.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity (MOQ) of 1 set or piece, allowing small-scale trials. Standard lead times range from 30 to 45 days post-deposit. Complex configurations with integrated peripherals may extend to 60 days. Expedited builds are occasionally available at a premium.

Can I customize the robotic arm’s specifications?

Yes, many suppliers offer customization in color, housing material, payload (from 3kg to 20kg), reach (600mm to 1800mm), and integration of sensors, vision systems, or proprietary control interfaces. Confirmation of in-house engineering teams and SDK availability is recommended prior to customization commitments.

Do suppliers provide technical support and training?

Leading suppliers typically include basic setup guides and remote troubleshooting. Advanced support—such as on-site installation, operator training, or API development assistance—may be offered as paid add-ons. Verify service scope during negotiation.

How are robotic arms packaged and shipped internationally?

Units are securely crated with foam padding and moisture barriers, meeting ISTA 3A standards. Most suppliers support FOB, CIF, and DDP shipping terms. Sea freight is optimal for multi-unit orders, while air freight enables delivery within 5–10 days for urgent single-unit shipments.