Robot Factory In China

Top sponsor listing

Top sponsor listing

1/3

1/3

1/33

1/33

CN

CN

1/25

1/25

1/15

1/15

1/24

1/24

1/14

1/14

1/2

1/2

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/1

1/1

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About robot factory in china

Where to Find Robot Factory Suppliers in China?

China remains the global epicenter for robotics manufacturing, with key industrial hubs concentrated in Shanghai, Guangdong, Shandong, and Jiangsu provinces. These regions host vertically integrated factories equipped with in-house R&D, CNC machining, assembly lines, and automation testing facilities. Proximity to component suppliers—such as servo motors, controllers, and structural alloys—enables streamlined production cycles and cost efficiency. Suppliers in these clusters typically operate dedicated robotic production lines, supporting both standard models and OEM/ODM configurations.

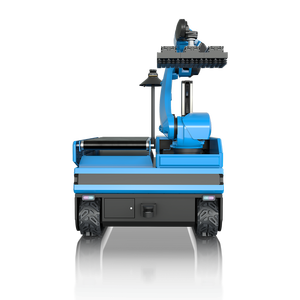

The ecosystem benefits from mature supply chains that reduce material procurement lead times by 25–40% compared to non-specialized regions. Factories often maintain modular production systems capable of rapid reconfiguration for different robot types, including collaborative arms, delivery units, cleaning robots, and industrial manipulators. Buyers gain access to scalable output capacities, with lead times averaging 15–30 days for standard orders and 30–45 days for customized solutions. Localization also supports lower MOQs (as low as 1 unit) and flexible packaging, labeling, and branding options.

How to Choose a Reliable Robot Factory in China?

Selecting a qualified supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Production & Engineering Capability

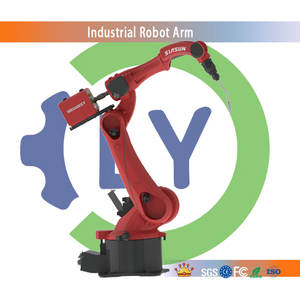

Prioritize manufacturers with documented ownership of their production lines and engineering teams. Key indicators include in-house CNC machining, welding, calibration labs, and software integration capabilities. For industrial or collaborative robots, verify experience with precision components such as harmonic drives, motion control algorithms, and safety-rated sensors. Suppliers should provide technical documentation on repeatability (±0.02mm to ±0.05mm), payload capacity (3–20kg typical), and IP ratings for environmental resistance.

Quality Assurance Protocols

Confirm adherence to international standards such as ISO 9001 for quality management and CE marking for EU market compliance. While not all suppliers list certifications explicitly, performance metrics like on-time delivery rates above 94% and reorder rates exceeding 20% indicate operational reliability. Request test reports for endurance, load cycling, and EMI/EMC performance where applicable.

Customization & Support Infrastructure

Evaluate customization depth beyond basic color or logo changes. Leading suppliers offer modifications in gripper integration, communication protocols (Modbus, Ethernet/IP), power supply (24V DC vs. AC), and AI-driven navigation systems for mobile robots. Assess responsiveness—suppliers with sub-2-hour average reply times demonstrate stronger customer engagement. Video audits of factory floors and real-time order tracking enhance transparency.

Transaction Security & Export Readiness

Favor suppliers with verifiable transaction histories and online revenue disclosures. Use secure payment mechanisms such as escrow services until product inspection is completed. Confirm export experience through shipping records and familiarity with Incoterms (FOB, CIF). Pre-shipment inspections and sample validation are critical to verifying build quality before full-scale orders.

What Are the Top Robot Factories in China?

| Company Name | Location | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Shanghai, CN | Conveyors, Cargo Equipment, Manipulators, Weighing Scales, Material Handling Systems | Automation specs, colors | 100% | ≤5h | 100% | US $60,000+ | Multispecialty Supplier |

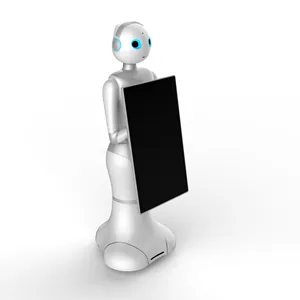

| Guangzhou Robin Intelligent Robot Co., Ltd | Guangzhou, CN | Commercial Delivery Robots, Cleaning Robots, Reception Robots | Limited customization | 100% | ≤2h | 20% | US $30,000+ | - |

| Jinan Lingyu International Trade Co., Ltd. | Jinan, CN | 6-Axis Industrial Robotic Arms, CNC Robot Arms | Color, material, size, logo, packaging, label, graphic | 90% | ≤1h | 30% | US $40,000+ | Multispecialty Supplier |

| Sypo Robot Technology (Nantong) Co., Ltd. | Nantong, CN | Automated Production Lines, Robotic Systems Integration | Color, material, size, logo, packaging, label, graphic | 100% | ≤5h | - | - | Multispecialty Supplier |

| Shandong Rayman Cnc Equipment Co., Ltd. | Shandong, CN | Industrial Robot Arms, Collaborative Robots, Mini Robotics | Grippers, logo, label, plasma/laser cutting integration | 94% | ≤2h | 22% | US $770,000+ | Custom Manufacturer |

Performance Analysis

Senad Robot stands out with a perfect 100% reorder rate and on-time delivery, indicating high buyer satisfaction and consistent fulfillment capability. Shandong Rayman leads in online revenue (US $770,000+), reflecting strong market penetration and export volume. Jinan Lingyu offers extensive customization breadth, while Guangzhou Robin excels in response speed (≤2h), crucial for iterative design coordination. Sypo Robot focuses on system-level integration, suggesting expertise in turnkey automated lines rather than standalone units. Buyers seeking high-volume industrial arms should prioritize Shandong- and Shanghai-based suppliers with proven CNC and welding infrastructure.

FAQs

How to verify a robot factory’s production capability?

Request facility videos showing active production lines, CNC stations, and testing procedures. Verify workforce size and R&D team presence. Cross-reference declared output volumes with actual transaction data and customer reviews focusing on delivery consistency.

What is the typical MOQ and lead time for robotic systems?

MOQ ranges from 1 set for commercial robots to 1 km/kg for production line integrations. Standard lead times are 15–30 days post-deposit; custom designs may require 30–45 days depending on complexity.

Do Chinese robot factories support OEM/ODM services?

Yes, most suppliers listed offer OEM branding and ODM modifications. Common options include custom colors, logos, packaging, and functional adaptations such as specialized end-effectors or control interfaces.

Are industrial robots CE or ISO certified?

Certification varies by manufacturer. While not all list formal ISO 9001 or CE marks, performance indicators such as 94–100% on-time delivery suggest adherence to structured quality systems. Buyers must request certification documents directly for regulatory compliance.

How to manage risks when sourcing robots from China?

Mitigate risk through sample testing, third-party inspections, and staged payments. Use secure transaction platforms with dispute resolution. Validate software stability, mechanical durability, and after-sales support availability before scaling orders.