Robot Prototype Maker

Top sponsor listing

Top sponsor listing

About robot prototype maker

Where to Find Robot Prototype Maker Suppliers?

China remains a central hub for robot prototype manufacturing, with key suppliers concentrated in Shenzhen, Dongguan, and Guangzhou—cities renowned for their advanced electronics, rapid prototyping infrastructure, and integrated supply chains. These regions host specialized fabrication clusters that combine precision machining, 3D printing (SLA, SLS, MJF), CNC processing, and low-volume production capabilities tailored for robotics development. The proximity of material suppliers, mold makers, and electronic component distributors enables streamlined prototyping workflows, reducing iteration cycles by up to 40% compared to offshore alternatives.

Suppliers in this ecosystem typically operate vertically integrated facilities capable of handling full-service prototype development—from initial design validation to functional testing and small-batch assembly. This integration supports agile product development, particularly for robotics startups and R&D departments requiring fast turnaround on complex electromechanical systems. Buyers benefit from localized expertise in materials such as ABS, PC, PETG, nylon, and polycarbonate, along with surface treatments including sandblasting, painting, electroplating, and vacuum casting.

How to Choose Robot Prototype Maker Suppliers?

Selecting the right supplier requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Manufacturing Capabilities

Prioritize suppliers offering multi-process fabrication options: SLA/SLS 3D printing for high-detail models, CNC machining for metal or rigid plastic components, and injection molding for scalable low-volume runs. Confirm access to industrial-grade equipment capable of tolerances within ±0.1mm. In-house design support—including 3D modeling, DFM analysis, and structural simulation—is critical for optimizing robot enclosures, gear trains, and sensor housings.

Quality Assurance & Process Control

While formal certifications (e.g., ISO 9001) are not explicitly listed in available data, performance indicators such as on-time delivery rates (ranging from 94% to 100%) and reorder rates (up to 80%) serve as proxies for reliability. Suppliers with response times under 5 hours demonstrate operational responsiveness crucial during iterative design phases. Evaluate whether post-processing services—such as polishing, labeling, splicing, or matte/gloss finishes—are standardized and documented.

Customization & Scalability

Assess customization depth beyond basic geometry: Can the supplier accommodate Pantone color matching, embedded hardware integration, or functional testing? Look for evidence of end-to-end project management, including mold-making, real estate-scale model replication, or IoT-enabled robot prototyping. High reorder rates (e.g., 80%) suggest strong client retention driven by consistent quality and adaptability.

Procurement Safeguards

Utilize incremental engagement: Start with a single-unit prototype order to evaluate dimensional accuracy, material finish, and communication efficiency. Require digital deliverables such as STL files, inspection reports, or process videos before scaling. Confirm packaging protocols for fragile assemblies and verify export experience with international shipping partners to mitigate transit risks.

What Are the Best Robot Prototype Maker Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Notable Strengths |

|---|---|---|---|---|---|---|---|---|

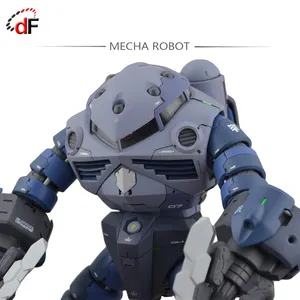

| Shenzhen Tongyi Technology Co., Ltd. | Shenzhen, CN | Robotics Kits (179), Toy Robots (165) | 94% | 16% | ≤2h | US $160,000+ | Color, material, size, logo, packaging, graphic | Highest online revenue; broad product catalog; fast response |

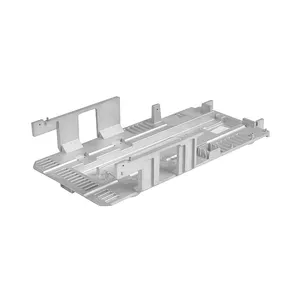

| Dongguan Yyi Technology Co., Ltd. | Dongguan, CN | Machining Services (168) | 100% | 58% | ≤3h | US $40,000+ | N/A | Perfect delivery record; focused on precision machining |

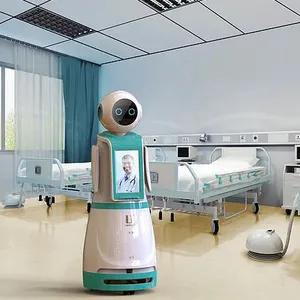

| Guangzhou Gaojie Model Design And Manufacturing Co., Ltd. | Guangzhou, CN | Plastic Parts, Medical/Logistics Robots | 96% | 48% | ≤4h | US $80,000+ | Engraving, plating, painting, 3D scan, mold making, resin printing | Extensive surface and material customization; medical-grade applications |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangzhou, CN | Machining Services (545), Moulds (66) | 100% | 80% | ≤5h | US $30,000+ | N/A | Highest reorder rate; robust machining and tooling capacity |

| Ganzhou Point Creation E-Commerce Co., Ltd. | Ganzhou, CN | Machining Services (556) | 100% | - | ≤4h | US $4,000+ | N/A | Consistent delivery; cost-effective entry-level prototyping |

Performance Analysis

Shenzhen-based Tongyi leads in market presence and customization breadth, ideal for buyers seeking diverse robotics kits and branding flexibility. Dongguan Yyi and the two Guangzhou Gaojie entities exhibit superior operational discipline with 100% on-time delivery, indicating reliable production planning. Notably, one Gaojie entity achieves an exceptional 80% reorder rate—suggesting high client satisfaction in engineering collaboration and output consistency. Although Ganzhou Point Creation has lower revenue volume, its perfect delivery performance makes it a viable option for budget-conscious projects. Buyers should prioritize suppliers with proven experience in robotic system integration, especially those offering vacuum casting or titanium alloy processing for durable prototypes.

FAQs

What materials are commonly used in robot prototyping?

Standard thermoplastics include ABS, PC, PETG, and nylon for structural parts. Transparent resins (PC-like) are used for sensor covers or aesthetic elements. Metal alloys such as titanium or brass may be incorporated via CNC for load-bearing components.

What is the typical lead time for a robot prototype?

Simple 3D-printed models take 3–7 days. Complex assemblies involving CNC machining, mold creation, or surface finishing require 10–20 days. Add 5–10 days for international shipping via express courier.

Is customization available for robot enclosures and internal frames?

Yes, most suppliers support full geometric and cosmetic customization, including size modification, Pantone color matching, logo engraving, and rail/splicing configurations. Technical drawings or 3D CAD files are required for accurate quoting.

What is the minimum order quantity (MOQ)?

MOQ is typically 1 unit, allowing for single-prototype validation. Pricing scales favorably at 10+ units, especially for injection-molded or machined batches.

Do suppliers provide design feedback or DFM support?

Leading suppliers offer free design for manufacturability (DFM) reviews to optimize wall thickness, draft angles, and assembly sequences. Request this service early to avoid rework and reduce lead time.