Virtual Prototype Maker

About virtual prototype maker

Where to Find Virtual Prototype Maker Suppliers?

China leads in virtual prototype manufacturing, with key production hubs in Shenzhen, Shanghai, and Guangzhou driving innovation in smart wearable and extended reality (XR) hardware development. These regions host vertically integrated supply chains combining rapid prototyping, precision machining, and electronics integration, enabling end-to-end product realization from concept to functional model. Shenzhen excels in VR/AR headset prototyping with access to BOE displays and pancake optics, while Shanghai and Guangzhou specialize in low-volume, high-mix custom prototypes using SLA, SLS, and urethane casting techniques.

The industrial clusters support agile development cycles through co-located design firms, material suppliers, and testing facilities—reducing iteration time by up to 40% compared to decentralized sourcing. Suppliers typically operate lean facilities optimized for flexibility rather than mass production, offering MOQs as low as one unit. This ecosystem enables cost-efficient prototyping, with average pricing between $0.10–$50 per unit depending on complexity, materials, and finishing requirements. Lead times range from 3–15 days for standard prototypes, making these regions ideal for R&D teams requiring fast turnaround.

How to Choose Virtual Prototype Maker Suppliers?

Procurement decisions should be guided by technical capability, responsiveness, and quality assurance protocols:

Prototyping Technology & Materials

Verify compatibility with required fabrication methods: SLA, SLS, CNC machining, vacuum casting, or injection molding. Key materials include ABS, TPU, nylon, resin, and metal alloys. Confirm supplier expertise in multi-part assemblies, electronic integration, and surface finishes such as electroplating, painting, or bonding.

Quality and Compliance Verification

While formal certifications like ISO 9001 are less commonly listed, prioritize suppliers demonstrating consistent quality through on-time delivery rates exceeding 97%. Evaluate their ability to maintain tight tolerances (±0.05mm typical for CNC, ±0.1mm for 3D printing) and adherence to design specifications. For consumer electronics applications, ensure RoHS compliance and EMI shielding capabilities where applicable.

Customization and Communication Efficiency

Assess customization depth via available options: STL file processing, color matching, labeling, logo embedding, and packaging design. Response time is a critical indicator of operational efficiency—top performers reply within 2–5 hours. Reorder rates above 40% suggest strong client satisfaction, particularly among suppliers offering iterative design support.

Transaction and Risk Mitigation

Opt for suppliers with transparent pricing structures and flexible MOQ policies. Use milestone-based payments for complex builds and request physical or digital samples before scaling. Validate production claims through video audits or third-party inspection services when placing orders over $5,000.

What Are the Best Virtual Prototype Maker Suppliers?

| Company Name | Location | Main Products | MOQ | Avg. Unit Price | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Shanghai Yunyan Prototype And Mould Manufacture Factory | Shanghai, CN | SLA 3D Printing, Custom VR Helmets, Electroplated Enclosures | 1 piece | $0.20–1.00 | 100.0% | ≤3h | 46% | US $60,000+ |

| Guangzhou Gaojie Model Design & Manufacturing Co., Ltd. | Guangzhou, CN | SLA/SLS Prototypes, Silicone Molding, Robotics Models | 1 unit | $0.22–5.21 | 100.0% | ≤5h | 80% | US $30,000+ |

| Shenzhen Strongd Model Technology Co., Ltd. | Shenzhen, CN | CNC Machining, Urethane Casting, Smart Electronic Prototypes | 1 piece | $0.10–5.00 | 97.0% | ≤2h | 41% | US $50,000+ |

| Shenzhen All Vision Technology Co., Ltd. | Shenzhen, CN | Micro-OLED Pancake Headsets, 6DoF VR/MR Devices | 1–1,000 units | $200–7,900 | 100.0% | ≤5h | - | - |

| Ganzhou Point Creation E-Commerce Co., Ltd. | Ganzhou, CN | CNC Plastic Prototypes, Electronic Enclosures, Mechanical Parts | 1 piece | $10–50 | 100.0% | ≤4h | - | US $4,000+ |

Performance Analysis

Guangzhou Gaojie stands out with an 80% reorder rate, indicating high client retention likely driven by reliable delivery and broad material/process flexibility. Shanghai Yunyan offers the lowest per-unit costs and extensive customization, supported by a robust $60,000+ annual online revenue track record. Shenzhen-based suppliers focus on higher-value XR hardware, with All Vision providing complete headset prototypes at premium price points ($2,000+), suitable for enterprise and medical applications. Ganzhou Point Creation serves niche mechanical and electronic enclosure needs with mid-range pricing and solid responsiveness. Buyers seeking fast-turn, low-cost iterations should prioritize Shanghai and Guangzhou suppliers, while those developing commercial-grade VR systems benefit from Shenzhen’s ecosystem integration.

FAQs

How to verify virtual prototype maker reliability?

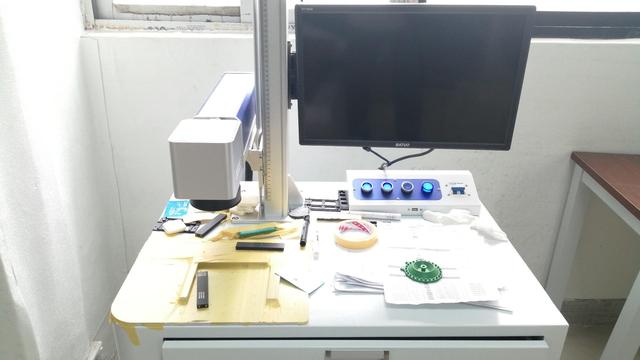

Review on-time delivery performance, response time metrics, and reorder rates as proxies for service consistency. Request sample work logs or STL-to-part validation reports. Conduct video calls to assess technical team competence and equipment condition.

What is the typical prototyping lead time?

Standard prototypes take 3–7 days for 3D printed or cast parts, and 7–15 days for CNC-machined or multi-process builds. Expedited services may reduce timelines by 30–50% with rush fees.

Can suppliers integrate electronics into prototypes?

Yes, select manufacturers offer embedded PCBs, wiring harnesses, sensor mounting, and battery compartments, particularly those specializing in smart wearables and headsets. Confirm design-for-assembly (DFA) support during initial consultations.

Do suppliers provide design feedback or DFM analysis?

Many offer free Design for Manufacturing (DFM) reviews to optimize part geometry, material selection, and assembly processes. This is especially common among CNC and injection molding-focused providers.

Are there hidden costs in prototype sourcing?

Potential add-ons include tooling for silicone molds ($100–$500), post-processing (painting, plating), and shipping for fragile models. Always confirm all-inclusive quotes before order placement.