Robots Scara

Top sponsor listing

Top sponsor listing

1/5

1/5

1/3

1/3

1/11

1/11

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/9

1/9

1/3

1/3

1/25

1/25

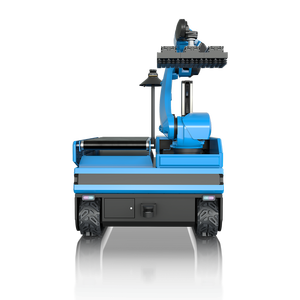

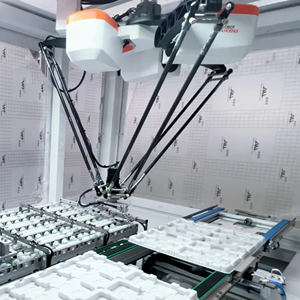

About robots scara

Where to Find SCARA Robot Suppliers?

China remains a central hub for SCARA robot manufacturing, with key production clusters in Shanghai, Jiangxi, and surrounding industrial zones driving innovation and cost efficiency. These regions host vertically integrated facilities that combine R&D, precision machining, and automation assembly under one roof, enabling rapid prototyping and scalable production. Shanghai-based suppliers benefit from proximity to advanced electronics and servo component suppliers, reducing lead times by 15–25% compared to offshore alternatives.

The ecosystem supports both high-volume standard models and engineered-to-order solutions, with many manufacturers operating automated production lines capable of monthly outputs exceeding 200 units per facility. Localized supply chains for linear guides, harmonic drives, and control systems allow for 20–30% lower unit costs while maintaining structural rigidity and repeatability down to ±0.01mm. Buyers gain access to agile suppliers equipped for just-in-time delivery, particularly for integration into pick-and-place, assembly, and material handling applications across electronics, pharmaceuticals, and food processing sectors.

How to Choose SCARA Robot Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm that suppliers offer validated performance metrics including repeatability (±0.01–0.05mm), payload capacity (3–10kg typical), and arm reach (400–700mm). Demand documentation for motion control systems, motor specifications, and optional vision or force feedback integration. CE marking is essential for European market compliance, while ISO 9001 certification indicates adherence to structured quality management processes.

Production Infrastructure Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum 3,000m² factory area supporting robotic calibration and testing zones

- In-house engineering teams capable of customizing stroke length, mounting configurations, and communication protocols (EtherCAT, Modbus, PROFINET)

- On-site CNC machining and gear assembly to ensure component traceability and reduce third-party dependency

Cross-reference response time data (target ≤7 hours) with on-time delivery rates above 98% as indicators of operational reliability.

Procurement Risk Mitigation

Utilize secure transaction mechanisms such as escrow services to protect payments until post-delivery acceptance testing is completed. Prioritize suppliers with documented after-sales support, including remote diagnostics and spare parts availability. Conduct pre-shipment inspections to validate functionality against agreed performance parameters. For customized units, request 3D CAD models and control interface simulations prior to production release.

What Are the Best SCARA Robot Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Sample MOQ |

|---|---|---|---|---|---|---|---|---|

| Senad Robot(Shanghai) Co., Ltd. | Shanghai, CN | Conveyors (342); Manipulator (77) | US $120,000+ | 100% | ≤7h | 100% | Automation specs, colors | 1 set |

| Ae Robotics Co., Ltd. | China | SCARA Robots (5 listed) | US $40,000+ | 100% | ≤4h | 20% | Color, size, logo, packaging | 1 set |

| Robotphoenix Intelligent Technology Co.,Ltd | China | Manipulator (594); AGV (217) | US $30,000+ | 100% | ≤3h | <15% | Limited public details | 1 set |

| Xiangjing (shanghai) Mechanical And Electrical Tech Co., Ltd. | Shanghai, CN | SCARA & Collaborative Models (5) | US $50,000+ | 100% | ≤7h | 16% | Color, material, labeling | 1 set |

| Jiangxi Longen Intelligent Equipment Co., Ltd. | Jiangxi, CN | BORUNTE SCARA Series (5) | US $1,000,000+ | 98% | ≤1h | 18% | Size, load, configuration | 1 unit/set |

Performance Analysis

Jiangxi Longen stands out with the highest reported online revenue (over US$1M) and fastest average response time (≤1h), indicating strong customer engagement despite a slightly lower on-time delivery rate (98%). Senad Robot demonstrates exceptional reorder performance (100%), suggesting high client retention likely driven by consistent quality and customization flexibility. Shanghai-based suppliers exhibit strategic advantages in automation integration expertise, while Jiangxi-based Longen offers competitive pricing—units start at $3,000—with scalability for mid-volume procurement. Suppliers like Ae Robotics and Xiangjing emphasize branding and packaging customization, making them suitable for OEM partnerships requiring private labeling.

FAQs

How to verify SCARA robot supplier credibility?

Validate certifications (CE, ISO 9001) through official registries and request test reports for cycle life (typically 50,000+ hours), IP rating (IP40 common), and electromagnetic compatibility. Analyze transaction history, focusing on dispute resolution outcomes and long-term buyer reviews related to system stability and technical support responsiveness.

What is the typical lead time for SCARA robots?

Standard models are typically available within 15–30 days after order confirmation. Custom configurations involving specialized end-effectors or software interfaces may require 45–60 days. Air freight adds 5–10 days for international delivery, while sea shipping ranges from 20–40 days depending on destination port.

Do suppliers support global shipping and customs clearance?

Yes, most established manufacturers export worldwide and provide FOB, CIF, or DDP shipping terms. They typically include necessary documentation—commercial invoice, packing list, bill of lading, and CE certificates—for customs processing. Confirm incoterms and import duties applicable in your region before finalizing orders.

Are samples available for testing?

Sample availability depends on model and supplier policy. Many offer functional units for evaluation at full price, with credit applied upon subsequent bulk orders. Expect sample costs between $3,000–$15,000 depending on payload and features. Some waive fees for confirmed large-scale integrations.

What level of customization can be expected?

Suppliers commonly support modifications to arm length, payload rating, cable routing, paint color, and communication protocols. Advanced options include integrated vision systems, tool changers, and IoT connectivity. Submit detailed technical requirements early in the sourcing process to assess feasibility and impact on lead time.