Roll Forming Machine Rajkot

CN

CN

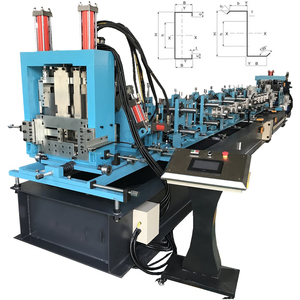

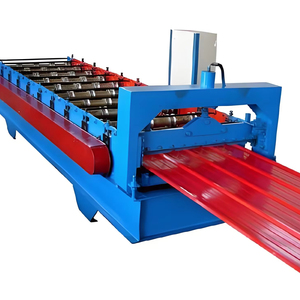

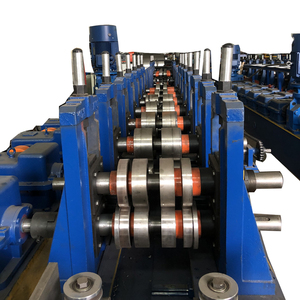

About roll forming machine rajkot

Where to Find Roll Forming Machine Suppliers in Rajkot?

Rajkot, a key industrial hub in Gujarat, India, has emerged as a regional nexus for metal fabrication machinery sourcing, particularly for roll forming machines used in roofing, shutter doors, purlins, and structural profiles. While domestic manufacturing is growing, the majority of high-capacity, export-grade roll forming machines are sourced from established Chinese manufacturers who supply globally via digital trade channels. These suppliers offer advanced cold bending technology with integrated automation, serving markets across South Asia, the Middle East, Africa, and Europe.

Chinese industrial clusters in Hebei, Henan, and Zhejiang provinces dominate global production, leveraging vertically integrated supply chains that reduce component procurement time by 25–40%. Facilities typically span 5,000–25,000 m², enabling batch production of standard models while maintaining flexibility for custom line configurations. Key advantages include competitive pricing (20–30% below European OEMs), rapid prototyping capabilities, and modular designs adaptable to local power and material specifications. Lead times for standard units range from 20–45 days, with sea freight logistics well-established for containerized shipping to Indian ports like Mundra and Pipavav, minimizing final delivery delays.

How to Choose Roll Forming Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Verify adherence to international quality benchmarks such as ISO 9001 for quality management systems. For export compliance, CE marking indicates conformity with EU safety and environmental standards—critical for buyers targeting regulated markets. Assess engineering capacity through product documentation: look for detailed CAD drawings, profile design software (e.g., Tekla or AutoCAD compatibility), and evidence of finite element analysis (FEA) for structural integrity under continuous load.

Production Infrastructure Audit

Evaluate supplier capability using verifiable metrics:

- Minimum factory area of 3,000 m² to ensure scalable output

- In-house CNC machining, welding, and heat treatment processes

- Dedicated R&D teams supporting customization (e.g., multi-profile changover systems)

Cross-reference on-time delivery rates (>95% recommended) and response times (≤3 hours) as indicators of operational efficiency and customer service commitment.

Customization and After-Sales Support

Confirm availability of end-to-end customization: material thickness range (typically 0.3–4.0 mm), coil width compatibility (up to 1,250 mm), speed settings (10–80 m/min), and integration with pre-punching, embossing, or cutting modules. Prioritize suppliers offering remote diagnostics, installation videos, and technician training programs—essential for minimizing downtime during commissioning.

What Are the Top Roll Forming Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| HENAN SUPERB MACHINERY CO., LTD. | Henan, CN | US $210,000+ | 95% | ≤3h | <15% | 5 listed models | $2,990–7,500 | Color, material size, logo, packaging, graphic |

| Hangzhou Willing International Co.,ltd | Zhejiang, CN | Not disclosed | 100% | ≤3h | No data | 5 specialized models | $26,000–76,000 | Limited customization noted |

| Cangzhou Huanuo Cold Bending Machine Co., Ltd. | Hebei, CN | US $820,000+ | 100% | ≤2h | <15% | 5 active listings | $2,500–12,500 | Shutter door size, thickness, design, profile, automatic adjustment |

| Zhengzhou Hokang Machinery Co., Ltd. | Henan, CN | US $280,000+ | 100% | ≤1h | 26% | 5 diverse models | $4,900–11,800 | Color, thickness, pattern, mold, drawing, labeling |

| Wuxi Hai Roll Fone Science And Technology Co., Ltd. | Jiangsu, CN | US $820,000+ | 75% | ≤4h | 100% | 5 technically varied units | $6,000–50,000 | Shape, speed, tube dimensions, prepainted coils, embossing |

Performance Analysis

Cangzhou Huanuo and Zhengzhou Hokang stand out for responsiveness (≤2h and ≤1h respectively) and full on-time delivery records, indicating strong operational discipline. HENAN SUPERB offers entry-level models starting at $2,990, ideal for small workshops seeking cost-effective solutions. Hangzhou Willing targets high-end applications with premium-priced machines (up to $76,000), reflecting specialization in precision steel framing and gutter systems. Wuxi Hai Roll Fone demonstrates exceptional customer retention (100% reorder rate), suggesting superior post-sale support despite a lower on-time delivery score. Buyers requiring complex multi-layer rack or solar panel profile machines should prioritize this supplier for proven reliability in niche segments.

FAQs

How to verify roll forming machine supplier reliability?

Cross-check certifications (ISO 9001, CE) with issuing bodies and request test reports for critical components like gearboxes, rollers, and control panels. Analyze transaction history, focusing on consistent on-time delivery performance and verifiable export experience. Video audits of production lines can confirm in-house manufacturing versus trading practices.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 set. Lead times vary from 20 days for stock models to 45 days for fully customized systems. Express production surcharges may reduce timelines by 30–50% for urgent deployments.

Can suppliers customize machine specifications?

Yes, most suppliers offer extensive customization: roller count (12–24 stations), motor power (3–30 kW), PLC brands (Siemens, Delta), and compatibility with galvanized, aluminum, or prepainted steel coils. Custom tooling for unique profiles is available upon submission of technical drawings.

Do manufacturers provide after-sales technical support?

Reputable suppliers offer remote troubleshooting via video call, English-language operation manuals, and spare parts supply agreements. Some include free technician training or on-site commissioning services at additional cost. Confirm support scope before order finalization.

Are samples available before bulk ordering?

While full-machine samples are impractical, suppliers can produce sample profiles using customer-specified materials and settings. These test runs, often provided free or at minimal cost, validate dimensional accuracy and surface finish prior to production release.