Rolling Shutter Machine Manufacturer In Rajkot

About rolling shutter machine manufacturer in rajkot

Where to Find Rolling Shutter Machine Manufacturers in Rajkot?

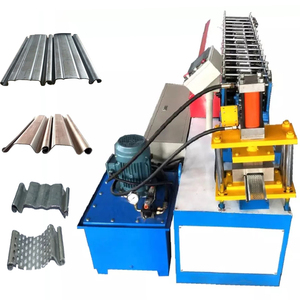

Rajkot, a key industrial hub in Gujarat, India, has emerged as a regional center for metal fabrication and automated door system manufacturing. While direct local production of complete rolling shutter machines remains limited, the city's robust ecosystem of sheet metal processing, automation integration, and mechanical engineering supports specialized suppliers focused on motors, control systems, and customized assembly solutions. Many Rajkot-based firms collaborate with Chinese OEMs that offer full-cycle manufacturing capabilities, particularly in Fujian and Hebei provinces, where vertically integrated facilities produce high-volume rolling shutter machinery at competitive costs.

These offshore manufacturing clusters benefit from concentrated supply chains—encompassing motor production, gearboxes, PLC controls, and roll-forming technology—allowing for rapid prototyping and scalable output. Buyers sourcing through Rajkot-linked suppliers gain access to hybrid models: locally coordinated project management combined with cost-efficient production from certified Chinese factories. This structure enables lead times averaging 30–45 days for standard configurations, with material cost savings of 20–35% compared to fully domestic Indian manufacturing, especially for automated central drive or side-winder rolling shutter systems.

How to Choose Rolling Shutter Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Product Range

Verify supplier specialization in rolling shutter motors and related automation components. Prioritize manufacturers offering CE-marked or RoHS-compliant electrical systems, particularly for export markets. Confirm availability of core product types: tubular (central) motors, surface-mounted (side) motors, and complete roll-forming lines for shutter panel fabrication. Demand documentation for thermal protection ratings, duty cycles, and IP classifications (e.g., IP65 for dust/water resistance).

Production and Customization Capability

Assess infrastructure indicators:

- Minimum factory area exceeding 3,000m² for dedicated assembly lines

- In-house engineering support for voltage customization (110V/220V/240V), radio frequency coding (433MHz), and torque range (300kg–800kg)

- Capacity for OEM labeling, color coding, and packaging modifications

Cross-reference listed product ranges with reorder rates and response times to gauge reliability and post-sale service efficiency.

Transaction Security & Quality Assurance

Utilize secure payment frameworks such as escrow services to mitigate risk until delivery confirmation. Evaluate suppliers’ historical performance metrics: target on-time delivery rates ≥97%, average response times ≤6 hours, and reorder rates indicating customer retention. Request sample units to test motor noise levels, cycle durability (minimum 10,000 open/close cycles), and compatibility with existing shutter profiles before bulk procurement.

What Are the Leading Rolling Shutter Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Hebei Liming Stamping Form Machine Co., Ltd. | Hebei, CN | Rolling Shutter Machines, Manual & Automatic Systems | US $530,000+ | 100.0% | ≤3h | <15% | Color, Material, Size, Logo, Packaging, Label, Graphic | 1 set |

| Zhangzhou Mingniao Electronic Machinery Co., Ltd. | Fujian, CN | Roller Shutter Motors, AC Motors, Garage Door Openers | US $10,000+ | 100.0% | ≤6h | <15% | Not specified | 1–50 sets |

| Zhangzhou Yinhe Mechanical&Electrical Technology Co. Ltd | Fujian, CN | Automatic Door Operators, AC Motors | US $30,000+ | 100.0% | ≤6h | 50% | Not specified | 10 sets |

| Zhangzhou Tianhui Eletromechanical Equipment Co., Ltd. | Fujian, CN | Rolling Shutter Motors, Remote Controls, Accessories | US $20,000+ | 100.0% | ≤4h | <15% | Not specified | 2–50 sets |

| Cangzhou Guangchi Machinery Co., Ltd. | Hebei, CN | Roller Shutter Door Making Machines, Steel Frame Lines | US $5,000+ | 100.0% | ≤2h | - | Not specified | 1 set |

Performance Analysis

Hebei Liming leads in customization breadth and revenue volume, offering end-to-end machine solutions with flexible MOQs starting at one unit. Zhangzhou Yinhe stands out with a 50% reorder rate, suggesting strong customer satisfaction despite higher minimum order thresholds. Cangzhou Guangchi and Hebei Liming specialize in full-scale roll-forming production lines priced between $5,200–$28,500, targeting commercial fabricators requiring in-house shutter panel manufacturing. The Fujian-based motor specialists (Mingniao, Yinhe, Tianhui) focus on component-level supply, ideal for integrators seeking reliable drive units priced between $38–$69/set. All top-tier suppliers maintain 100% on-time delivery records, with sub-6-hour average response times enhancing communication efficiency.

FAQs

How to verify rolling shutter machine supplier reliability?

Validate certifications (CE, ISO 9001) through official registries and request product test reports for insulation class, overload protection, and electromagnetic compatibility. Analyze transaction history via verified revenue data, delivery compliance, and customer feedback on after-sales responsiveness and spare parts availability.

What is the typical lead time for rolling shutter machines?

Standard orders require 25–40 days from confirmed purchase, including production and pre-shipment inspection. Customized configurations may extend timelines by 10–15 days depending on design complexity and component sourcing.

Can suppliers provide machinery with international voltage compatibility?

Yes, most manufacturers support dual-voltage options (110V/220V) and frequency adjustments (50/60Hz). Confirm input specifications during inquiry to ensure seamless integration into local power systems.

Do rolling shutter machine suppliers offer samples?

Sample policies vary. Some suppliers provide motor samples at reduced cost with credit toward future orders. For complete machines, expect sample fees covering 40–60% of unit price, refundable upon bulk contract execution.

What are common customization options for rolling shutter systems?

Key configurable parameters include lifting capacity (300kg–800kg), control method (remote/wall switch/app-based), chain drop length, mounting type (surface or recessed), and enclosure material (aluminum alloy or galvanized steel). Full OEM branding is available from leading manufacturers like Hebei Liming.