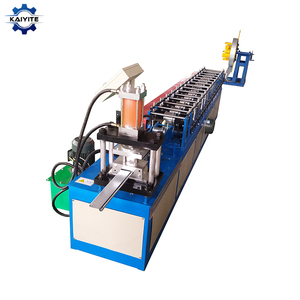

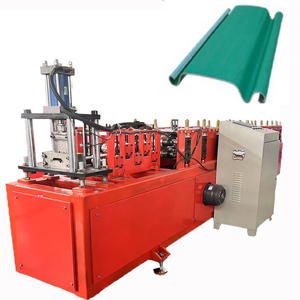

Rolling Shutter Spring Machine Price In India

CN

CN

1/19

1/19

1/10

1/10

1/33

1/33

1/28

1/28

1/65

1/65

1/21

1/21

1/11

1/11

1/16

1/16

1/14

1/14

CN

CN

1/28

1/28

About rolling shutter spring machine price in india

Where to Find Rolling Shutter Spring Machine Suppliers?

China remains the dominant hub for rolling shutter spring machine manufacturing, with key industrial clusters in Hebei, Tianjin, and Guangdong provinces offering specialized production ecosystems. The region around Botou City in Hebei Province hosts a concentrated network of machinery manufacturers specializing in door and shutter automation equipment, supported by integrated metal processing supply chains. These clusters enable cost efficiencies through localized sourcing of raw materials such as high-carbon steel wire and precision CNC components, reducing material procurement lead times by up to 40% compared to decentralized production models.

The proximity of component suppliers, heat treatment facilities, and logistics providers within 50–100 km radii supports rapid prototyping and scalable production. This vertical integration allows manufacturers to maintain competitive pricing while supporting both standard and customized configurations. Buyers benefit from shorter production cycles—typically 20–35 days for machine orders—and flexible MOQs ranging from single units to full container loads. Regional advantages include access to skilled labor pools, established export channels, and compliance-ready manufacturing frameworks aligned with international trade standards.

How to Choose Rolling Shutter Spring Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to ISO 9001 quality management systems as a baseline indicator of process control. For export markets requiring regulatory alignment, confirm CE marking or equivalent safety certifications applicable to electromechanical machinery. Request documentation on motor specifications, control systems (PLC or CNC), and mechanical tolerances to ensure compatibility with local power and operational environments.

Production Capability Assessment

Evaluate supplier infrastructure based on the following criteria:

- Minimum factory area exceeding 3,000m² for dedicated assembly lines

- In-house engineering teams capable of customizing coil diameter, wire feed rate, and spring pitch parameters

- Integration of CNC-controlled coiling and tension calibration systems

Cross-reference declared capabilities with on-time delivery performance (target ≥98%) and reorder rates to assess reliability and customer satisfaction.

Procurement Safeguards

Utilize secure payment mechanisms such as escrow services to mitigate financial risk until post-delivery inspection is completed. Prioritize suppliers with transparent transaction histories and verifiable after-sales support, including technical guidance for machine setup and maintenance. Conduct sample testing to validate output consistency, measuring dimensional accuracy and torsional strength of produced springs against industry benchmarks like DIN 2095 or ASTM A313.

What Are the Best Rolling Shutter Spring Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Beijing Ron-En Machinery And Integration Co., Ltd. | Spring Coiling Machine, Wire Drawing Machines, Metal Processing Lines | $9,800–$28,600 | 1 set | 100% | ≤10h | <15% | US $3,000+ |

| Botou Metalroll Machinery Co., Ltd. | Roller Shutter Machines, Door Forming Equipment | $7,500–$8,600 | 1 set | Not specified | ≤2h | <15% | US $10,000+ |

| Foshan Gishines Metals Industrial Limited | Roller Shutter Springs, Garage Doors, Shutters | $3.18–$3.50 | 200 pieces | 100% | ≤2h | 100% | US $200,000+ |

| Tianjin Lantoo International Trade Co., Ltd. | Springs, Pipe Clamps, Door & Window Accessories | $3.08–$5.88 | 1–50 pieces | 100% | ≤2h | 15% | US $30,000+ |

| PREMIER STEEL PROCESSORS | Galvanized Steel Strips, Mild Steel Springs | $0.82–$1.10 | 100–200 kg | Not specified | Not specified | Not specified | Not specified |

Performance Analysis

Beijing Ron-En and Botou Metalroll specialize in complete rolling shutter spring manufacturing machines, offering turnkey solutions priced between $7,500 and $28,600 per set. These suppliers cater to industrial buyers seeking automated production lines with CNC integration. In contrast, Foshan Gishines and Tianjin Lantoo focus on finished spring components, providing lower-cost entry points for businesses sourcing replacement parts or building in-house assembly operations. Foshan Gishines stands out with a 100% reorder rate and strong online revenue, indicating consistent product quality and buyer retention. Botou Metalroll offers customization options for color, size, and packaging, enhancing flexibility for branded distribution. While some suppliers lack disclosed performance metrics, response times under 2 hours suggest proactive customer engagement, particularly among Tianjin- and Guangdong-based exporters.

FAQs

What is the typical MOQ for rolling shutter spring machines?

For fully assembled machines, the standard MOQ is 1 set. Component suppliers may require 100–200 kilograms for steel strips or 200-piece minimums for pre-coiled springs. Some manufacturers offer sample orders at higher per-unit costs to facilitate initial testing.

How long does it take to fulfill a machine order?

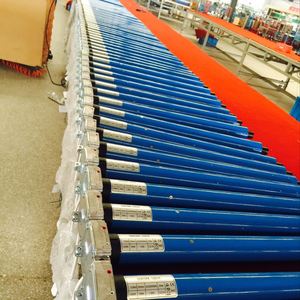

Lead times range from 20 to 35 days for standard configurations after deposit confirmation. Customized systems with PLC controls or integrated conveyors may extend production timelines to 45 days. Shipping via sea freight adds 25–40 days depending on destination port.

Can suppliers provide customized spring dimensions?

Yes, reputable manufacturers support customization of inner diameter, wire thickness, number of coils, and load capacity. Provide technical drawings or sample specimens to initiate engineering reviews. Most suppliers offer prototype development within 10–15 days.

Do suppliers offer installation and training support?

Some suppliers include remote technical guidance via video or manuals. On-site commissioning and operator training may be available at additional cost. Confirm service inclusions prior to purchase, especially for complex automated systems.

Are spare parts included with machine purchases?

Basic toolkits and wear-prone components (e.g., guide rollers, cutting blades) are often bundled. Extended spare parts packages can be negotiated during contract finalization. Verify availability of consumables like high-tension bearings and servo motors for long-term maintenance planning.