Rolling Shutter Machine Price In Mumbai

CN

CN

1/19

1/19

1/24

1/24

1/11

1/11

1/9

1/9

1/18

1/18

CN

CN

1/19

1/19

CN

CN

1/28

1/28

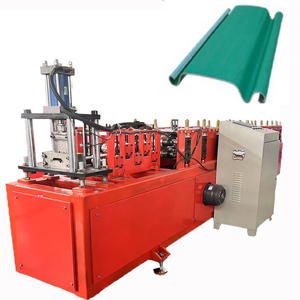

About rolling shutter machine price in mumbai

Where to Find Rolling Shutter Machine Suppliers?

China remains the dominant global hub for rolling shutter machine manufacturing, with key production clusters in Hebei, Henan, and Jiangsu provinces. These regions host vertically integrated facilities capable of producing complete roll-forming lines—from decoilers and feeding systems to hydraulic cutting units and PLC-controlled output conveyors. Botou City in Hebei Province alone accounts for over 40% of China’s shutter machinery output, supported by a dense network of steel processors and automation component suppliers within a 50km radius.

The industrial ecosystems in these zones enable cost efficiencies of 20–30% compared to equivalent European or Indian-built machines, primarily due to localized access to raw materials (such as 1.5–3mm galvanized steel coils) and in-house CNC machining capabilities. Standard lead times range from 25 to 40 days for fully assembled systems, with export-ready packaging and CE-compliant electrical panels increasingly standard across mid-tier and premium suppliers. Buyers benefit from scalable production capacity, with top-tier manufacturers reporting monthly outputs exceeding 80 sets per facility.

How to Choose Rolling Shutter Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify ISO 9001 certification as a baseline indicator of quality management systems. For international compliance, ensure machines meet CE standards—particularly in electrical safety (IEC 60204-1) and mechanical guarding. Request documentation on motor specifications (typically 3–7.5kW), roller shaft hardness (HRC 58–62 after heat treatment), and control systems (Siemens or Delta PLCs preferred).

Production Capacity Verification

Assess infrastructure indicators to confirm scalability:

- Minimum factory area of 3,000m² for dedicated roll-forming line assembly

- In-house CNC machining and welding stations to reduce outsourcing dependencies

- Dedicated R&D teams supporting customization (e.g., profile adjustment, integration of automatic punching modules)

Cross-reference on-time delivery rates (target ≥95%) and response times (≤2 hours) as proxies for operational efficiency.

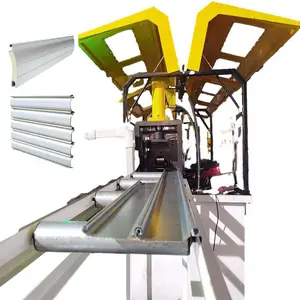

Customization and After-Sales Support

Leading suppliers offer full configurability including material thickness (0.6–2.0mm), roll station count (12–24 stations typical), and door profile compatibility (slat widths from 60mm to 120mm). Confirm availability of technical drawings, 3D modeling, and post-installation support such as remote diagnostics and spare parts supply. Video audits of production lines are recommended prior to large-volume orders.

What Are the Best Rolling Shutter Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Botou Metalroll Machinery Co., Ltd. | Hebei, CN | Custom Manufacturer | US $10,000+ | - | ≤2h | <15% | $7,500–8,600 | 1 set |

| Zhengzhou Hokang Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $280,000+ | 100% | ≤1h | 30% | $4,900–7,200 | 1 set |

| Wuxi Hai Roll Fone Science And Technology Co., Ltd. | Jiangsu, CN | Multispecialty Supplier | US $240,000+ | 100% | ≤3h | 100% | $8,000–10,000 | 1 set |

| Henan Wadley Cnc Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $930,000+ | 95% | ≤1h | 62% | $6,500–8,800 | 1 set |

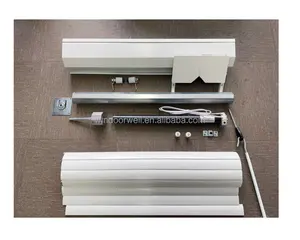

| Zhangzhou Orsenar Electronics Co., Ltd. | Fujian, CN | Not Listed | US $570,000+ | 96% | ≤3h | 23% | $45–200 | 2 sets |

Performance Analysis

Zhengzhou Hokang and Henan Wadley stand out for high reorder rates (30% and 62%, respectively) and rapid response times (≤1h), indicating strong customer service alignment. Wuxi Hai Roll Fone demonstrates exceptional loyalty metrics with a 100% reorder rate, suggesting consistent performance and reliability despite higher pricing. Botou Metalroll offers competitive pricing but lacks verified on-time delivery data and exhibits a low reorder rate, signaling potential gaps in post-sale support. Notably, Zhangzhou Orsenar focuses on motors rather than full machines, positioning it as a component supplier rather than a system integrator.

FAQs

What is the typical MOQ for rolling shutter machines?

Most suppliers list a minimum order quantity of 1 set, allowing flexibility for small-scale buyers and testing. Some component suppliers may require 2+ units for bundled items like motors.

How long does production and shipping take?

Manufacturing lead time averages 30 days for standard configurations. Add 25–35 days for sea freight to Indian ports like Mumbai or Chennai under FOB terms. Air freight is not viable for full machines due to size and weight.

Can suppliers customize machine specifications?

Yes, nearly all listed suppliers offer customization options including slat profile design, color coating compatibility, punching patterns, bending angles, and automated stacking systems. Technical drawings and configuration templates are typically provided upon inquiry.

Are CE and ISO certifications standard?

While not universal, reputable suppliers provide CE-marked control panels and comply with ISO 9001 standards. Buyers should explicitly request certification documents and verify conformity through third-party inspection services if required.

What payment and transaction protections are available?

Escrow-based payment systems and trade assurance programs help mitigate risk. Suppliers with verifiable revenue histories (e.g., >US $200,000/year) and high on-time delivery rates (>95%) present lower procurement risk. Pre-shipment inspections are advised for first-time transactions.