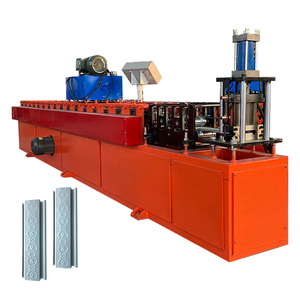

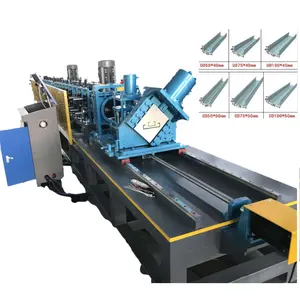

Rolling Shutter Patti Machine Price

1/11

1/11

CN

CN

1/19

1/19

1/10

1/10

1/14

1/14

1/11

1/11

1/11

1/11

1/9

1/9

1/20

1/20

About rolling shutter patti machine price

Where to Find Rolling Shutter Patti Machine Suppliers?

China remains the central hub for rolling shutter patti machine manufacturing, with key industrial clusters located in Henan and Hebei provinces. These regions host vertically integrated production ecosystems that combine raw material sourcing, cold-forming technology, and precision engineering under one supply chain. Henan province, in particular, accounts for over 50% of China’s roll-forming machinery output, supported by a dense network of component suppliers and skilled technical labor. The proximity to major steel production centers enables cost reductions of 15–25% on input materials such as galvanized, galvalume, and aluminum coils used in shutter slat fabrication.

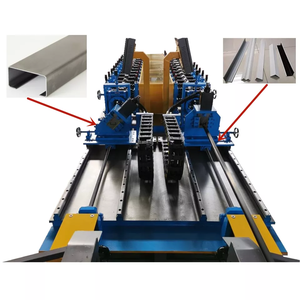

Manufacturers in this sector typically operate automated roll-forming lines capable of producing 8–12 meters per minute, with customization options for feed width (100–500mm), coil thickness (0.3–1.5mm), and profile design. Production facilities average 5,000–25,000m², allowing scalable output for both standard and engineered-to-order machines. Buyers benefit from localized logistics, with Zhengzhou and Shijiazhuang serving as primary export gateways, offering rail and sea freight connectivity to Southeast Asia, the Middle East, Africa, and Europe. Lead times for standard machine orders range from 25 to 40 days, while customized systems may require up to 60 days depending on complexity.

How to Choose Rolling Shutter Patti Machine Suppliers?

Selecting reliable suppliers requires due diligence across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

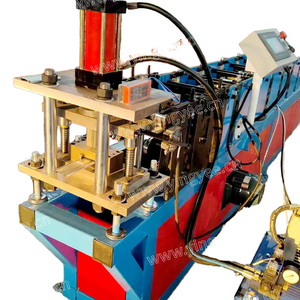

Verify adherence to international quality standards such as ISO 9001. While not always explicitly stated, CE compliance is critical for market access in Europe and indicates conformity with safety and electromagnetic compatibility directives. Request documentation on motor specifications (typically 3–7.5kW), roller shaft hardness (HRC 58–62), and gearbox types (planetary or cycloidal). Confirm testing procedures for continuous operation under load and alignment accuracy of formed profiles.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² to support dedicated R&D and assembly zones

- In-house machining capabilities including CNC lathes, milling, and welding stations

- Roller design expertise for multiple shutter profiles (round, square, louvered, double-layer)

- Customization capacity for voltage (220V/380V/415V), control panels (PLC or relay-based), and feeding mechanisms

Cross-reference online performance metrics such as on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours) as indicators of operational efficiency and customer service commitment.

Transaction Security & Procurement Best Practices

Utilize secure payment methods such as irrevocable LC or escrow services to mitigate risk. Prioritize suppliers with verifiable reorder rates above 25%, indicating post-sale satisfaction and machine reliability. Conduct video audits to validate facility claims and observe ongoing production. Request sample production runs or prototype units—especially for custom configurations—to assess build quality before full-scale ordering.

What Are the Best Rolling Shutter Patti Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Shijiazhuang Yingyee Machinery Co., Ltd. | Hebei, CN | US $2,600,000+ | 100% | ≤1h | 100% | $8,000–10,000 | Color, thickness, profile, size, packaging, logo, graphic |

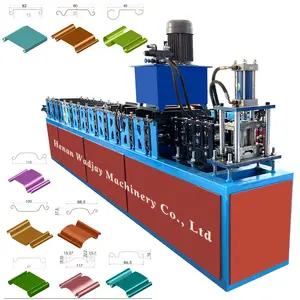

| Henan Wadjay Machinery Co., Ltd. | Henan, CN | US $370,000+ | 100% | ≤2h | 22% | $4,500–8,950 | Material, layer, feed width, pattern, label, roof plate forms |

| Henan Randro Machinery Equipment Co., Ltd. | Henan, CN | US $370,000+ | 100% | ≤2h | 50% | $6,800–26,000 | PU foam core, European profiles, double/triple layer, gutter design |

| Henan Jane Machinery Co., Ltd. | Henan, CN | US $70,000+ | 100% | ≤1h | 31% | $5,200–5,800 | Limited (focus on standard models) |

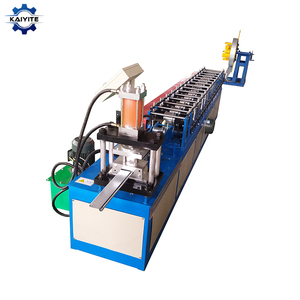

| Botou Kaiyite Cold Bending Machinery Co., Ltd. | Hebei, CN | US $150,000+ | 100% | ≤3h | 25% | $5,000–6,900 | Material, size, logo, packaging, graphic |

Performance Analysis

Shijiazhuang Yingyee stands out with a 100% reorder rate and sub-hour response time, suggesting strong post-delivery support and customer retention. Henan-based manufacturers offer competitive pricing, with entry-level machines starting at $4,500, making them suitable for budget-conscious buyers in emerging markets. Henan Randro distinguishes itself in high-end segments, offering PU-insulated and multi-layer shutter lines priced above $20,000, catering to European and climate-sensitive applications. Botou Kaiyite provides cost-effective semi-automatic solutions ideal for small workshops, while Henan Jane focuses on standardized production with minimal customization. Buyers seeking turnkey automation should prioritize suppliers offering PLC integration, automatic cutting, and stacking systems.

FAQs

What is the typical MOQ for rolling shutter patti machines?

The standard minimum order quantity is 1 set, which is common across all major suppliers. This allows flexibility for individual buyers, distributors, and small manufacturers to procure without volume commitments.

What materials can these machines process?

Most rolling shutter patti machines are designed for cold-rolled steel, galvanized steel, galvalume, and aluminum coils. Thickness ranges from 0.3mm to 1.5mm, with customizable roll sets required for different materials and profiles.

Do suppliers offer customization?

Yes, leading suppliers provide extensive customization including voltage, control systems, roller count, motor power, and profile geometry. Some offer full OEM services with branding, packaging, and multilingual manuals. Confirmation via technical drawings and video validation is recommended prior to production.

What are the common lead times?

Standard machine delivery takes 25–40 days after deposit confirmation. Customized systems with specialized rollers or automation features may extend to 50–60 days. Air freight is rarely used due to size and weight; sea freight (LCL or FCL) is the standard shipping method.

Are samples available before purchase?

While full machine samples are impractical, suppliers often provide formed shutter slats produced on the same line. Video demonstrations of running machines, along with factory test reports, serve as effective pre-shipment verification tools.