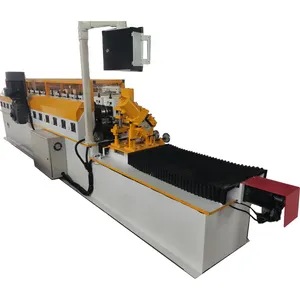

Rolling Shutter Patti Making Machine

1/11

1/11

CN

CN

1/17

1/17

1/19

1/19

CN

CN

1/19

1/19

1/11

1/11

1/35

1/35

1/25

1/25

CN

CN

1/17

1/17

1/13

1/13

1/27

1/27

1/9

1/9

CN

CN

1/18

1/18

About rolling shutter patti making machine

Where to Find Rolling Shutter Patti Making Machine Suppliers?

China remains the dominant hub for rolling shutter patti making machine manufacturing, with key production clusters concentrated in Henan and Hebei provinces. These regions host vertically integrated industrial ecosystems specializing in metal forming machinery, supported by localized steel supply chains and advanced roll-forming technology. Henan, in particular, accounts for over half of China’s door and shutter equipment producers, leveraging proximity to raw material suppliers and major logistics corridors for efficient export operations.

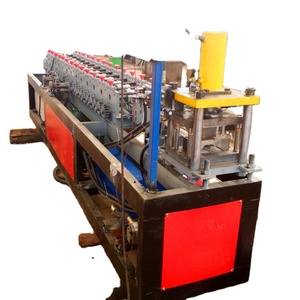

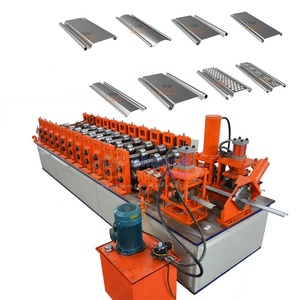

The region's mature supplier base benefits from economies of scale, enabling competitive pricing and rapid customization. Integrated facilities typically encompass coil processing, roll forming, hydraulic cutting, and profile calibration lines—all within compact manufacturing zones. This clustering reduces component lead times and supports agile production cycles, with standard machines deliverable within 20–40 days. Buyers gain access to a diverse range of configurations, including manual, semi-automatic, and fully automated systems designed for GI, aluminum, and galvalume sheets.

How to Choose Rolling Shutter Patti Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

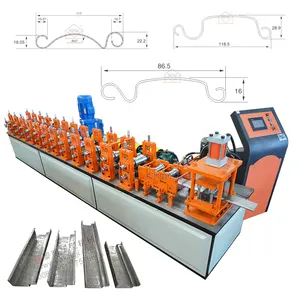

Technical Compliance & Design Capability

Verify adherence to international quality standards such as ISO 9001. While not universally declared, CE marking indicates compliance with European safety and environmental directives—critical for market entry in regulated regions. Assess engineering capacity through availability of customization options: feed width (typically 800–1,250mm), material thickness (0.2–1.5mm), roller count (12–24 stations), and profile design flexibility. Suppliers offering CAD/CAM modeling, 3D drawings, and servo-driven non-stop cutting systems demonstrate higher technical maturity.

Production Capacity Verification

Evaluate infrastructure indicators to ensure scalability:

- Facility size exceeding 5,000m² suggests volume production capability

- In-house CNC machining and welding units reduce outsourcing dependencies

- Dedicated R&D teams support custom profile development and process optimization

Cross-reference on-time delivery rates—suppliers achieving 100% punctuality (as observed in top-tier vendors) reflect robust production planning and inventory control.

Transaction Security & After-Sales Support

Prioritize suppliers with transparent transaction histories, including verifiable reorder rates and response efficiency. Use secure payment mechanisms such as escrow services until post-delivery inspection is completed. Confirm availability of technical documentation, operator training, and spare parts supply. Video audits and real-time communication via calls or factory walkthroughs enhance due diligence, especially when evaluating remote partners.

What Are the Best Rolling Shutter Patti Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) | Key Product Features |

|---|---|---|---|---|---|---|---|---|

| Henan Wadjay Machinery Co., Ltd. | Henan, CN | US $370,000+ | 100% | 28% | ≤2h | Yes | $3,900–7,900 | Automatic operation, servo non-stop cutting, multi-layer shutter compatibility |

| Xiamen Rollmac Building Technology Co., Ltd. | Xiamen, CN | US $10,000+ | 100% | 33% | ≤1h | Yes | $7,000–15,000 | High durability, steel/iron slat forming, full roll-forming line integration |

| Hebei Ironstar Industry Co., Ltd. | Hebei, CN | US $80,000+ | 100% | <15% | ≤2h | No | $7,000–12,000 | Hydraulic cutting, high-speed no-stop systems, used/refurbished units available |

| Henan Olilang Machinery Co., Ltd. | Henan, CN | US $50,000+ | 86% | <15% | ≤2h | No | $1,400–5,400 | Manual spring-based models, cost-effective entry-level solutions |

| CQ MECHANICAL TECHNOLOGY INC | Chongqing, CN | Not disclosed | Not available | Not available | ≤2h | No | $1,500–3,650 | Low-cost food machinery hybrids—potential misalignment with industrial shutter requirements |

Performance Analysis

Henan Wadjay and Xiamen Rollmac stand out for their strong customization capabilities, 100% on-time delivery, and responsive communication. Xiamen Rollmac achieves the highest reorder rate (33%), indicating strong customer retention likely driven by tailored engineering solutions. Hebei Ironstar offers competitive pricing with high-end features like no-stop cutting but exhibits lower repeat order volume. Henan Olilang provides budget-friendly options, though its 86% delivery rate suggests potential fulfillment risks. Notably, CQ Mechanical lists products under the same keyword cluster but primarily markets food processing equipment—highlighting the need for careful product verification to avoid category mismatches.

FAQs

How to verify rolling shutter patti machine supplier reliability?

Cross-check claimed certifications with official databases. Request evidence of past exports, customer references, and third-party inspection reports. Conduct virtual audits to assess workshop conditions, machinery assembly processes, and quality control checkpoints such as alignment testing and stress monitoring.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set across suppliers. Lead times range from 15–30 days for standard models and extend to 40 days for customized configurations involving unique profiles or automation integrations.

Can these machines handle different materials and thicknesses?

Yes, most industrial-grade machines support material thicknesses between 0.3–1.5mm in galvanized iron, aluminum, or pre-painted steel. Confirm maximum yield strength (typically up to 350 MPa) and required roll hardness (HRC 58–62) to ensure compatibility with target substrates.

Do suppliers offer installation and training?

Reputable manufacturers provide setup guidance, operational manuals, and video tutorials. Some offer on-site technician deployment at additional cost. Confirm inclusion of electrical schematics, maintenance protocols, and spare part kits before finalizing procurement.

Are second-hand or refurbished machines available?

Yes, select suppliers like Hebei Ironstar list used or refurbished rolling shutter machines priced between $7,000–$8,500. Buyers should request detailed condition reports, usage history, and reconditioning records to assess value and longevity.