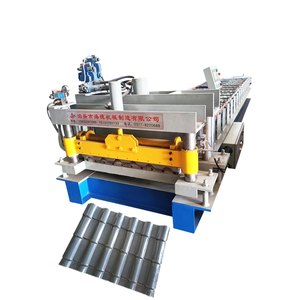

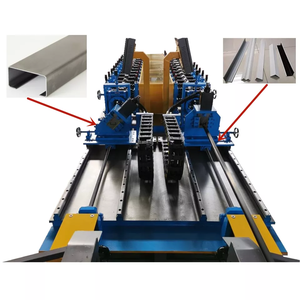

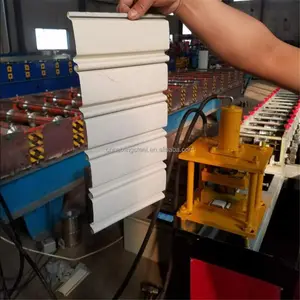

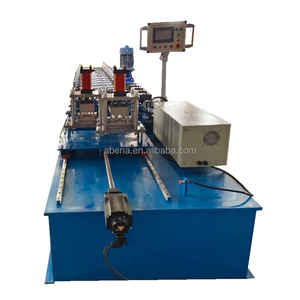

Shutter Strip Making Machine

CN

CN

CN

CN

CN

CN

About shutter strip making machine

Where to Find Shutter Strip Making Machine Suppliers?

China remains the global epicenter for shutter strip making machine manufacturing, with key production clusters concentrated in Hebei and Tianjin provinces. These regions host vertically integrated industrial ecosystems specializing in metal forming machinery, supported by mature supply chains for steel processing, roll forming components, and automation systems. Hebei alone accounts for over 70% of China’s window and door machinery exporters, leveraging proximity to Tangshan’s steel hubs and Xingtai’s component manufacturers to reduce raw material lead times by 25–30%.

The region’s supplier density enables rapid prototyping and scalable production, with most facilities operating within 50 km of coil steel suppliers, CNC workshops, and logistics terminals. This integration supports average delivery cycles of 30–45 days for standard configurations, while localized sourcing reduces unit costs by 18–22% compared to European or Southeast Asian alternatives. Buyers benefit from flexible MOQs (typically 1 set) and access to full production lines—from decoilers to punching and cutting units—engineered for galvanized, aluminum, and Aluzinc coils ranging from 0.3mm to 1.5mm thickness.

How to Choose Shutter Strip Making Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to ISO 9001 standards as a baseline for quality management. For international compliance, confirm CE marking for electrical systems and safety guarding. Request documentation on roller shaft hardness (ideally HRC 58–62), bearing specifications (e.g., NSK or SKF), and PLC brands (Siemens, Delta, or Mitsubishi) used in control systems.

Production Capability Audits

Assess infrastructure maturity through verifiable metrics:

- Minimum factory area exceeding 3,000m² to support assembly and testing

- In-house engineering teams capable of custom profile design and tooling fabrication

- Integrated processing capabilities including CNC machining, welding, and roll grinding

Cross-reference response times (target ≤4 hours) and on-time delivery rates (>90%) to validate operational reliability.

Transaction Safeguards

Utilize secure payment mechanisms such as trade assurance or escrow services until equipment validation is complete. Prioritize suppliers with documented export experience to your region and request references for after-sales service performance. Pre-shipment inspections should include dry-run testing with customer-specified material thickness and profile width.

What Are the Best Shutter Strip Making Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Product Range | Verified Supplier |

|---|---|---|---|---|---|---|---|---|

| Botou Shengrui International Trade Co., Ltd. | Hebei, CN | US $510,000+ | 100% | ≤3h | 100% | Diameter, size, thickness, width | Roller shutter slat machines, customizable forming lines | Yes |

| Tianjin Ironstar Industry Co., Ltd. | Tianjin, CN | US $1,700,000+ | 92% | ≤2h | 50% | Color, foam thickness, profile, material, design, width | Polyurethane-filled, guide rail, PPGI-based systems | Yes |

| Cangzhou Zhongheng Machine Manufacture Co.,ltd. | Hebei, CN | US $410,000+ | 100% | ≤4h | 100% | Strip cutting quantity, customization | Full-automatic slat machines, warehouse garage models | No |

| Hebei Ironstar Industry Co., Ltd. | Hebei, CN | US $80,000+ | 100% | ≤2h | <15% | Limited (implied via product range) | Electric-operated, PU foam slat, frame guide rail systems | No |

| Steelmama Machinery Inc | Hebei, CN | Data not available | Not reported | ≤3h | Not reported | Euro-type, PU insulation, automatic control | Metal slat, warm panel, automatic Euro-type models | No |

Performance Analysis

Botou Shengrui and Cangzhou Zhongheng demonstrate strong buyer loyalty, both achieving 100% reorder rates and perfect on-time delivery records—indicative of consistent quality and post-sale support. Tianjin Ironstar leads in revenue volume (US $1.7M+) and offers extensive customization, particularly for insulated PU foam shutters, though its 92% on-time rate suggests occasional logistical delays. Hebei Ironstar stands out for responsiveness (≤2h) but has a low reorder rate (<15%), potentially signaling gaps in long-term satisfaction. Suppliers with verified status and multi-category expertise (e.g., tile and purlin machinery) tend to offer more robust engineering support for complex roll forming needs.

FAQs

How to verify shutter strip making machine supplier reliability?

Validate certifications through issuing body databases. Request video audits of production floors and test runs. Analyze transaction history for consistent order fulfillment and review feedback on technical documentation accuracy and spare parts availability.

What is the typical lead time for shutter strip machines?

Standard models require 30–45 days after deposit confirmation. Customized systems with PU injection or specialized drives may extend to 60 days. Air freight is impractical due to weight; sea shipping (FCL/LCL) is standard for international orders.

Can suppliers accommodate custom shutter profiles?

Yes, most established suppliers support OEM profile design using CAD/CAM software. Provide detailed drawings specifying bend radii, rib depth, and interlock geometry. Tooling modification typically adds $800–$2,000 and extends lead time by 7–10 days.

What materials are compatible with these machines?

Primary input materials include galvanized steel (GI), aluminum-zinc alloy (Aluzinc), and pre-painted galvanized iron (PPGI), with thicknesses from 0.3mm to 1.5mm. Machines designed for PU foam filling integrate injection units for thermal insulation during forming.

Do suppliers provide installation and training?

Most offer remote commissioning support via video. On-site installation and operator training are often available at additional cost ($150–$250/day plus travel). Confirm inclusion of operation manuals, circuit diagrams, and maintenance schedules in the quotation.