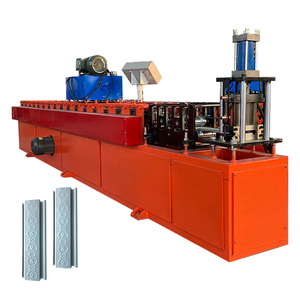

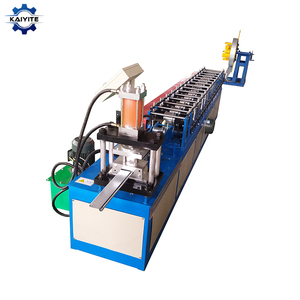

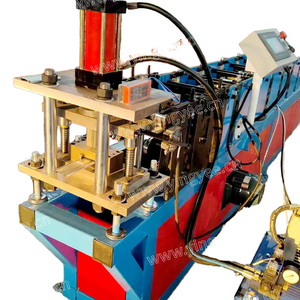

Rolling Shutter Patti Machine

About rolling shutter patti machine

Where to Find Rolling Shutter Patti Machine Suppliers?

China remains the dominant hub for rolling shutter patti machine manufacturing, with concentrated production clusters in Henan and Hebei provinces. These regions host vertically integrated facilities that combine roll forming technology, CNC machining, and structural design expertise. Henan, particularly around Zhengzhou, supports over 60% of China’s light industrial machinery exporters, leveraging established logistics networks for efficient global shipping. Hebei's Cangzhou and Langfang zones specialize in precision metal forming equipment, benefiting from proximity to major steel production centers, which reduces raw material lead times by 20–25% compared to offshore alternatives.

These industrial ecosystems enable suppliers to offer scalable production capacity, with average factory sizes exceeding 5,000m² and monthly output ranging from 15 to 30 units per line. Buyers benefit from localized supply chains that support rapid prototyping, reduced component costs, and flexibility in customization. Standard lead times for non-custom machines typically range from 30 to 45 days, while bulk orders (10+ sets) can achieve cost efficiencies of 15–25% due to economies of scale.

How to Choose Rolling Shutter Patti Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify ISO 9001 certification as a baseline for quality management systems. For export markets in Europe or North America, CE marking is essential for regulatory compliance and customs clearance. Request documentation on material testing, roller shaft hardness (typically HRC 58–62), and motor load endurance reports. Confirm compatibility with common input materials such as galvanized steel, galvalume, and aluminum coils (0.4–1.5mm thickness).

Production Capability Audits

Assess infrastructure maturity through key indicators:

- Minimum factory area of 3,000m² to ensure dedicated assembly and testing zones

- In-house engineering teams capable of providing CAD drawings, profile designs, and simulation videos

- Integrated processes including decoiling, leveling, roll forming, punching, cutting, and packaging

Cross-reference on-time delivery performance (target ≥95%) and response time metrics (ideally ≤2 hours) to gauge operational responsiveness.

Transaction Safeguards

Utilize secure payment methods such as third-party escrow services until final inspection at destination. Prioritize suppliers with verifiable online transaction histories and reorder rates above 30%, indicating customer satisfaction. Conduct sample testing to validate slat dimensional accuracy (±0.2mm tolerance), surface finish quality, and structural consistency before full-scale procurement.

What Are the Best Rolling Shutter Patti Machine Suppliers?

| Company Name | Location | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

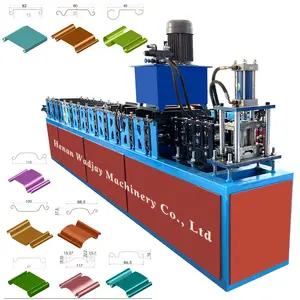

| Henan Wadjay Machinery Co., Ltd. | Henan, CN | 100% | ≤2h | 27% | $370,000+ | Color, thickness, pattern, logo, feed width, profile, double/triple layer | $4,500–7,400 | 1 set |

| Henan Wadjay Machinery Inc | Henan, CN | - | ≤1h | - | - | Limited customization noted | $4,500–10,500 | 1 set |

| Hebei Xinnuo Roll Forming Machine Co., Ltd. | Hebei, CN | 100% | ≤4h | 57% | $890,000+ | Steel type, color, thickness, profile, packaging, decoiler design | $4,500–14,800 | 1 set |

| Xiamen Rollmac Building Technology Co., Ltd. | Xiamen, CN | 100% | ≤1h | 33% | $10,000+ | Material, size, color, logo, packaging | $7,000–15,000 | 1 set/piece |

| Henan Wadley Cnc Machinery Co., Ltd. | Henan, CN | 95% | ≤1h | 62% | $930,000+ | Thickness, color, configuration, profile, logo, packaging, shearing dimensions | $6,500–8,800 | 1 set |

Performance Analysis

Hebei Xinnuo and Henan Wadley stand out for high reorder rates (57% and 62%, respectively), indicating strong post-sale satisfaction and technical reliability. Henan-based suppliers dominate response efficiency, with three companies answering inquiries within one hour. Xiamen Rollmac offers the widest price band ($7,000–15,000), reflecting adaptability to both standard and engineered configurations. Hebei Xinnuo commands premium pricing due to advanced customization in multi-layer profiles and insulation integration. For buyers prioritizing proven scalability and documentation transparency, suppliers with verified revenue streams above $800,000 are recommended. Always confirm machine control systems (PLC brands like Delta or Siemens), roller count (12–18 stations typical), and punch station integration prior to order placement.

FAQs

How to verify rolling shutter patti machine supplier reliability?

Cross-check ISO/CE certifications with issuing bodies. Request factory audit reports or video walkthroughs showing active production lines. Analyze transaction data including on-time delivery history, reorder rate, and customer reviews focusing on after-sales service and technical support responsiveness.

What is the average lead time for standard machines?

Standard rolling shutter patti machines typically require 30–45 days for production and pre-shipment inspection. Customized models with specific profile designs or automation features may extend lead times to 60 days.

Do suppliers support international shipping and installation?

Yes, most suppliers manage FOB and CIF shipments globally. Sea freight is standard for containerized loads. Some offer optional technician dispatch for on-site commissioning at additional cost—confirm availability and associated fees during negotiation.

Are free samples available for rolling shutter slats?

Sample policies vary. Many suppliers provide free slat samples produced on the same machine line when accompanied by a formal purchase intent. For complex profiles, expect nominal charges covering material and setup costs, often deductible from future orders.

What level of customization is possible?

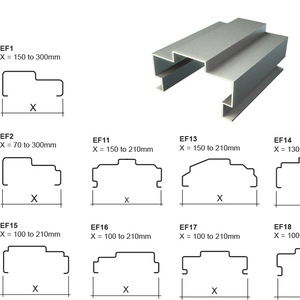

Suppliers commonly support adjustments in material thickness (0.3–2.0mm), coil width (up to 1,250mm), profile depth (40–120mm), and layer configuration (single, double, or triple). Custom tooling for unique side guides or interlocking mechanisms is available, subject to minimum order requirements and NRE fees.