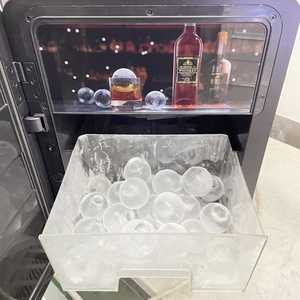

Round Ice Block Maker

1/22

1/22

1/25

1/25

1/28

1/28

1/26

1/26

1/4

1/4

1/11

1/11

1/20

1/20

1/24

1/24

1/12

1/12

1/35

1/35

About round ice block maker

Where to Source Round Ice Block Maker Suppliers?

China remains the central hub for round ice block maker production, with supplier clusters concentrated in Guangdong, Jiangsu, and Henan provinces. Guangdong-based manufacturers specialize in consumer-grade reusable molds made from food-safe plastics and silicone, leveraging proximity to raw material suppliers and export ports like Guangzhou and Shenzhen. In contrast, industrial machinery producers are primarily located in Henan and Nantong, where integrated refrigeration engineering ecosystems support the development of large-scale automatic ice-making systems.

These regional specializations enable targeted sourcing strategies: Guangdong excels in low-cost, high-volume mold manufacturing with rapid turnaround, while northern industrial zones offer advanced capabilities in commercial and industrial freezing technology. The geographic distribution allows buyers to optimize procurement based on application—household or barware versus hotel, restaurant, or processing plant operations. Vertical integration in these regions ensures access to full production chains, from injection molding and die casting to refrigerant system assembly, reducing component dependency risks and improving delivery predictability.

How to Evaluate Round Ice Block Maker Suppliers?

Effective supplier assessment requires a structured evaluation across technical, operational, and transactional dimensions:

Product & Material Specifications

Verify material compliance for direct food contact applications. Reusable molds should be constructed from BPA-free PP, PE, or food-grade silicone, with thermal resistance tested between -20°C and 120°C. For commercial ice machines, confirm refrigerant type (e.g., R404A, R134a), compressor quality (hermetic vs. semi-hermetic), and insulation standards. Request material safety data sheets (MSDS) and, where applicable, FDA or EU 1935/2004 compliance documentation.

Production Capacity and Lead Times

Assess scalability through verified output metrics:

- Minimum Order Quantity (MOQ) ranging from 50–100 pieces for plastic molds to 1 set for industrial machines

- Standard lead time of 15–30 days for molded products; 30–60 days for custom-engineered ice-making systems

- Evidence of in-house tooling and mold-making capabilities to support design iterations

Cross-reference stated capacity with online revenue indicators and order history to validate reliability under volume demand.

Quality Assurance and Compliance

Prioritize suppliers with documented quality management systems. While ISO 9001 certification is not universally present, evidence of consistent on-time delivery (>95%) and internal QC protocols should be confirmed. For electrical components in automated units, CE marking and IEC 60335 safety standards are essential for European market entry. Request test reports on cycle durability (for molds) and ice yield consistency (for machines).

What Are the Leading Round Ice Block Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Guangzhou Raybin Homewares Co., Ltd. | Guangdong, CN | Multispecialty Supplier | US $600,000+ | 92% | ≤2h | 28% | Color, material, size, logo, packaging, label, graphic |

| Nantong Bolang Energy Saving Technology Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $160,000+ | 98% | ≤2h | <15% | Color, material, size, logo, packaging, label, graphic |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $450,000+ | 98% | ≤2h | 30% | Color, material, size, logo, packaging, label, graphic |

| Shangqiu Bingya Refrigeration Equipment Co., Ltd. | Henan, CN | Not Specified | US $30,000+ | 100% | ≤2h | <15% | Popsicle machine, Ice Machines, Refrigeration Equipment |

| Kaifeng Rainbow Machinery Co., Ltd. | Henan, CN | Not Specified | US $10,000+ | 95% | ≤2h | <15% | Grain Product Making Machines, Food Processing Machinery |

Performance Analysis

Guangzhou Raybin and Zhengzhou Yize demonstrate strong reorder performance (28% and 30%, respectively), indicating customer satisfaction in consumer mold segments. Nantong Bolang and Shangqiu Bingya focus on commercial and industrial equipment, with Nantong offering scalable customization for refrigeration systems and Shangqiu providing mid-range ice column and clear block machines priced between $300–$800 per unit. Despite lower online revenue, Shangqiu Bingya achieves perfect on-time delivery (100%), suggesting efficient order execution. Zhengzhou Yize stands out with higher reorder rates and a broad industrial portfolio, including used ice block machines for cost-sensitive buyers. All top-tier suppliers maintain sub-2-hour response times, ensuring timely communication for technical clarifications and order tracking.

FAQs

What is the typical MOQ for round ice block makers?

For reusable plastic or silicone molds, MOQ ranges from 50 to 100 pieces. Industrial ice-making machines typically have an MOQ of 1 set. Some suppliers offer sample orders at reduced quantities with adjusted pricing.

How long does it take to receive samples?

Sample production for molds takes 7–14 days, with express shipping adding 5–7 business days internationally. Customized or motorized ice machines may require 20–30 days for prototype assembly and testing before shipment.

Can suppliers customize ice block size and shape?

Yes, most suppliers support dimensional adjustments within mold design limits. Common sphere diameters range from 50mm to 70mm. For industrial systems, custom ice block weights (e.g., 5kg, 10kg) and ejection mechanisms can be engineered upon request, subject to minimum order requirements.

Do manufacturers provide certifications for export compliance?

While not all suppliers hold ISO or CE certifications, leading vendors can provide product-specific test reports and material compliance documentation. Buyers should explicitly request CE, RoHS, or EAC certificates if required for import clearance in target markets.

What payment and transaction protections are available?

Suppliers commonly accept T/T, L/C, and platform-mediated payments with trade assurance. For high-value machinery, escrow services and milestone-based disbursements are recommended. Always confirm inspection rights prior to shipment and clarify warranty terms for mechanical components.