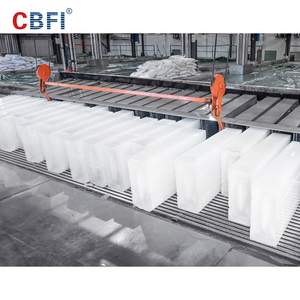

Polar Temp Ice Block Maker

CN

CN

CN

CN

About polar temp ice block maker

Where to Find Polar Temp Ice Block Maker Suppliers?

China remains the central hub for industrial ice block maker production, with key manufacturing clusters in Henan and Guangdong provinces driving innovation and cost efficiency. Henan-based suppliers dominate in stainless steel fabrication and modular ice plant systems, leveraging localized access to raw materials and precision machining resources. Guangdong’s refrigeration technology corridor, particularly around Guangzhou, specializes in temperature-optimized, energy-efficient ice block makers with advanced cooling cycles and digital controls.

These regional ecosystems support vertically integrated manufacturing—encompassing compressor assembly, evaporator tube forming, and food-grade mold casting—within compact supply chains. This integration enables lead times as short as 20–35 days for standard configurations and supports scalable output from 50kg/day tabletop units to 1-ton industrial plants. Buyers benefit from 25–40% lower unit costs compared to Western or Southeast Asian manufacturers, alongside robust customization capabilities for block size, freezing time, and power specifications (air-cooled vs. water-cooled systems).

How to Choose Polar Temp Ice Block Maker Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation protocols:

Technical Compliance & Quality Assurance

Confirm adherence to international quality benchmarks such as ISO 9001 for quality management systems. For exports to regulated markets (EU, North America), verify CE marking and compliance with electrical safety and refrigerant handling standards (e.g., RoHS, REACH). Request test reports on compressor performance, insulation efficiency, and condensate management under sustained operation.

Production Capacity Verification

Assess operational scale through objective metrics:

- Minimum factory area exceeding 3,000m² for consistent batch production

- In-house capabilities for CNC bending, welding, and refrigerant charging

- Use of food-grade stainless steel (SS304/SS316) and certified compressors (Copeland, Danfoss, or equivalent)

- Demonstrated experience with containerized or modular ice plant installations

Cross-reference online transaction volume and on-time delivery rates (>97%) to validate reliability. Prioritize suppliers offering real-time video audits of assembly lines and mold calibration processes.

Customization & Transaction Security

Ensure flexibility in design parameters: block dimensions (typically 2.5kg–10kg), daily output (50kg–1,000kg), voltage (220V/380V), and refrigerant type (R404A, R134a, or eco-friendly alternatives). Require third-party payment protection mechanisms and pre-shipment inspection clauses. Conduct sample testing to benchmark ice clarity, cycle time, and energy consumption before scaling orders.

What Are the Best Polar Temp Ice Block Maker Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Zhengzhou Hento Machinery Co., Ltd. | Henan, CN | Brand Holder | US $440,000+ | 100.0% | ≤1h | 15% | Mold size, color, capacity, logo, packaging |

| Zhengzhou Yize Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $390,000+ | 97% | ≤2h | 30% | Block size, refrigerant, compressor, cooling method, insulation |

| Wellcooling Intelligent Technology (JM) Co., Ltd. | Henan, CN | - | US $140,000+ | 100.0% | ≤9h | 16% | Limited; focused on core ice machine line |

| Henan Reso Machinery Co.,Ltd | Henan, CN | - | US $130,000+ | 100.0% | ≤2h | <15% | Limited; broad machinery portfolio |

| Guangzhou Baiyu Refrigeration Equipment Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $6,000+ | 100.0% | ≤1h | <15% | Color, size, logo, label, packaging, graphic |

Performance Analysis

Zhengzhou Hento and Zhengzhou Yize lead in technical customization depth and post-sale engagement, with Yize exhibiting the highest reorder rate (30%), indicating strong client retention despite a slightly lower on-time delivery score. Hento stands out for rapid response (≤1h) and brand ownership, suggesting greater control over product quality. Guangzhou Baiyu, though newer in revenue scale, offers extensive aesthetic and packaging personalization ideal for branded commercial deployments. Henan-based suppliers collectively demonstrate superior delivery consistency (all ≥100%), while Guangdong-based manufacturers provide stronger design adaptability. For high-volume industrial buyers, prioritize suppliers with documented experience in containerized ice plants and refrigerant compliance certifications.

FAQs

How to verify polar temp ice block maker supplier credibility?

Validate certifications through official databases and request factory audit reports covering material sourcing, weld integrity testing, and compressor run-in procedures. Analyze customer feedback focusing on after-sales service, spare parts availability, and system durability under continuous operation.

What is the typical MOQ and pricing range?

Standard MOQ is 1 set across most suppliers. Pricing varies by capacity: compact models (50–100kg/day) start at $555/set, mid-range systems (300–500kg) range from $1,490–$1,980, while large-scale 1-ton units exceed $2,999. Custom engineering may increase MOQ to 2–3 sets.

Do suppliers support global shipping and installation?

Yes, experienced exporters offer FOB and CIF shipping terms with sea freight recommended for full-container loads. Some provide optional installation supervision or remote commissioning support. Confirm compatibility with local voltage and plumbing codes prior to shipment.

Are free samples available for ice block makers?

Full-machine samples are rarely free due to size and complexity. Buyers typically pay full price for initial units, which may be credited toward larger orders. Functional prototypes or component samples (e.g., ice molds) may be offered at reduced cost upon request.

How long does customization take?

Engineered-to-order modifications require 25–40 days depending on scope. Simple changes (color, branding) add 5–7 days; major reconfigurations (output capacity, refrigerant type) necessitate design validation and testing, extending lead time by 2–3 weeks.