Scissors Sharpener Producer

CN

CN

About scissors sharpener producer

Where to Find Scissors Sharpener Producers?

China remains the central hub for scissors sharpener manufacturing, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains specializing in precision tooling, abrasive materials, and compact mechanical assembly. Ningbo and Zhongshan serve as primary industrial bases, offering mature ecosystems where component sourcing, machining, and final packaging occur within tightly coordinated networks. This localization reduces lead times by up to 25% compared to offshore alternatives and supports rapid scalability for both manual and electric sharpener variants.

Manufacturers in these zones typically operate multi-process facilities capable of CNC machining, injection molding, surface treatment, and automated assembly. The concentration of specialized subcontractors—ranging from carbide insert suppliers to diamond-coated grinding wheel producers—enables efficient prototyping and batch production. Buyers benefit from established logistics corridors that support containerized shipping via Ningbo Port and Guangzhou Baiyun International Airport, ensuring reliable delivery timelines for global distribution.

How to Choose Scissors Sharpener Producers?

Selecting a qualified producer requires verification across technical, operational, and transactional dimensions:

Production and Engineering Capability

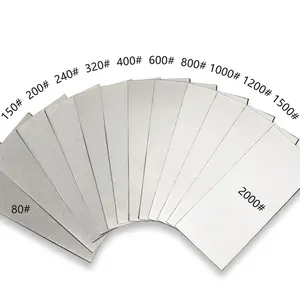

Assess whether suppliers possess in-house tooling and mold-making capacity, particularly for adjustable-angle sharpeners requiring precision guides and alignment mechanisms. Look for evidence of R&D involvement through product variants such as 4-in-1 or 6-in-1 systems integrating multiple grit stages. Suppliers offering OEM/ODM services should demonstrate experience with material selection (e.g., tungsten carbide, diamond abrasives) and ergonomic design validation.

Quality Assurance Systems

While formal ISO 9001 certification is not universally declared in available data, consistent on-time delivery performance serves as an indirect indicator of process control. Prioritize suppliers reporting 100% on-time fulfillment rates and response times under 2 hours, which correlate with structured internal workflows. For electric models, verify compliance with electrical safety standards such as CE or RoHS, especially when targeting EU or North American markets.

Order Flexibility and Transaction Metrics

Evaluate minimum order quantities (MOQs), which range from 2 pieces for high-value units to 2,000 bags for disposable-style sharpeners. Lower MOQs may indicate readiness for trial orders but require scrutiny of unit economics. Cross-reference online revenue estimates—where disclosed above US $30,000—with reorder rates; higher repeat purchase percentages (e.g., 31–33%) suggest customer satisfaction despite competitive pricing environments.

What Are the Leading Scissors Sharpener Producers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Ningbo Shangxiang Houseware Co., Ltd. | Zhejiang, CN | Sharpeners, Kitchen Tools | $1.30–3.30 | 100 packs | 100% | ≤1h | US $70,000+ | <15% |

| Jiangyin Diamond Tools Ltd., Co. | Jiangsu, CN | Diamond Sharpeners, Custom Tools | $1.85–$19.00 | 1–2 pcs | 98% | ≤2h | US $20,000+ | <15% |

| Risam Kitchen (Zhongshan) Co., Ltd. | Guangdong, CN | Manual & Electric Sharpeners | $3.30–$31.90 | 50–200 pcs | 100% | ≤3h | US $30,000+ | <15% |

| Taisun Tech. (Zhongshan) Co., Ltd. | Guangdong, CN | Smart Sharpeners, Abrasive Tools | $3.20–$3.90 | 500–2,000 pcs | 100% | ≤3h | US $330,000+ | 31% |

| Foshan Wanniu Electric Appliance Co., Ltd. | Guangdong, CN | Motorized & Electronic Sharpeners | $3.88–$10.13 | 50 pcs | 100% | ≤2h | US $20,000+ | 33% |

Performance Analysis

Taisun Tech. and Foshan Wanniu stand out for higher reorder rates (31% and 33%, respectively), indicating strong market acceptance of their motorized and multi-stage sharpening solutions. Taisun also reports the highest online revenue (US $330,000+), suggesting robust export activity and digital sales infrastructure. Foshan Wanniu offers low MOQs starting at 50 pieces with competitive pricing for mid-tier electric models, making it suitable for niche branding or regional test launches. In contrast, Jiangyin Diamond Tools provides highly flexible sampling (as low as 1 piece) and customization options including color, logo, and packaging—ideal for private-label development. Ningbo Shangxiang excels in responsiveness (≤1h average reply time) and perfect delivery consistency, advantageous for time-sensitive procurement cycles.

FAQs

What are typical lead times for scissors sharpener production?

Standard orders typically require 20–30 days from confirmation to shipment. Custom tooling or molded components may extend timelines by 10–15 days. Express production options are occasionally available for stock-compatible designs, reducing lead time to 12–18 days with premium fees.

Can manufacturers provide free samples?

Sample policies vary. Some producers offer paid samples with cost recovery upon bulk order placement. Units priced above $10 often incur full sample charges, while simpler models may be provided at reduced rates. Free samples are generally limited to established buyers or large-volume prospects.

Do scissors sharpener producers support OEM/ODM?

Yes, several suppliers explicitly list customization capabilities including logo imprinting, color variation, packaging redesign, and structural modifications. Jiangyin Diamond Tools and Taisun Tech. highlight ODM/OEM service offerings, supported by in-house design input and prototype development.

What materials are commonly used in scissors sharpeners?

Key materials include tungsten carbide for coarse blades, diamond-coated abrasives for fine finishing, and aluminum alloy or reinforced plastic for housing. Electric models incorporate small motors with rotating ceramic or diamond wheels. Material durability directly impacts edge retention and user safety during repeated use.

How to verify manufacturer claims independently?

Request factory audit reports or video walkthroughs to confirm equipment and workflow conditions. Validate export history through shipment records or third-party trade data platforms. For quality assurance, conduct independent lab testing on delivered samples, focusing on angle accuracy, blade hardness, and electrical safety (for powered units).