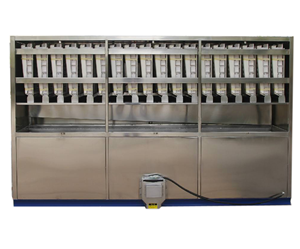

Scotch Ice Cube Maker

About scotch ice cube maker

Where to Find Scotch Ice Cube Maker Suppliers?

China serves as the central hub for ice-making equipment manufacturing, with key industrial clusters in Guangdong, Shanghai, and Henan provinces driving innovation and production efficiency. Guangdong, particularly Shenzhen and Guangzhou, hosts a high concentration of suppliers specializing in both commercial-grade ice machines and consumer-oriented silicone molds. These regions benefit from mature refrigeration technology ecosystems and proximity to ports, enabling faster export cycles—typically 25–35 days for standard orders.

The supplier base is bifurcated into two primary segments: industrial ice machine producers and custom mold manufacturers. Companies in Guangzhou and Shanghai focus on large-capacity Scotsman-type cube makers, with daily outputs ranging from 60kg to over 1,000 lbs. Meanwhile, Shenzhen-based firms dominate the niche market for premium whiskey ice accessories, leveraging advanced silicone processing and private-label customization. This regional specialization allows buyers to source either heavy-duty commercial systems or branded consumer products with equal precision.

How to Choose Scotch Ice Cube Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Product Type & Capacity Alignment

Clarify whether the requirement is for full-scale commercial ice machines (refrigerant-driven, stainless steel construction) or consumer-grade silicone trays/molds. Commercial units typically range from $1,100–$2,200 per set with minimum order quantities (MOQ) of 1 piece, while silicone molds start at $0.62/unit with MOQs between 50–100 pieces. Confirm compatibility with intended use—e.g., clear ice production for premium bars versus rapid-cycle cubes for hotels.

Manufacturing & Customization Capabilities

Evaluate suppliers based on material expertise and value-added services:

- In-house tooling and mold design teams for custom cavity shapes (sphere, square, crushed)

- BPA-free food-grade silicone or stainless steel 304/316 compliance documentation

- Private labeling, color Pantone matching, and packaging customization options

Suppliers like Shenzhen Helpcook Technology and Shenzhen Benhaida offer end-to-end OEM/ODM support, including graphic design and regulatory labeling for North American and EU markets.

Quality Assurance & Operational Metrics

Prioritize suppliers with verified performance indicators:

- On-time delivery rate ≥95%

- Response time under 7 hours, ideally ≤4h

- Reorder rate above 15% indicating customer retention

Cross-reference these metrics with production scale—suppliers reporting annual online revenues exceeding $250,000 demonstrate consistent order fulfillment and market demand validation.

What Are the Best Scotch Ice Cube Maker Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Snowland Refrigeration Equipment Co., Ltd. | Commercial Ice Machines (Scotsman-type) | $400–$2,165 | 1 set/piece | 100% | ≤7h | $150,000+ | 16% | Limited |

| Shenzhen Helpcook Technology Co., Ltd. | Silicone Ice Trays & Ball Molds | $1.34–$18.80 | 50–100 pieces/sets | 95% | ≤4h | $290,000+ | 21% | Full OEM/ODM |

| Shanghai Snowman Electrical Equipment Co., Ltd. | High-Capacity Vertical Ice Machines | $1,100–$1,815 | 1 piece | 100% | ≤6h | $40,000+ | <15% | Standard models only |

| Zhengzhou Bingrong Information Technology Co., Ltd. | Block & Cube Ice Machines | $1,499–$2,000 | 1 piece | 100% | ≤4h | $50,000+ | <15% | Limited |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | BPA-Free Silicone Ice Molds | $0.62–$2.36 | 1–100 pieces | 93% | ≤3h | $250,000+ | <15% | Full OEM/ODM |

Performance Analysis

Guangzhou Snowland and Shanghai Snowman lead in commercial ice machine reliability, both maintaining 100% on-time delivery with robust stainless-steel unit offerings suitable for restaurants and industrial kitchens. For consumer-focused brands, Shenzhen Helpcook and Benhaida provide superior customization agility, supported by sub-4-hour response times and comprehensive private-label services. Notably, Helpcook achieves a 21% reorder rate—the highest among listed suppliers—indicating strong buyer satisfaction in the silicone accessory segment. While Benhaida offers the lowest per-unit pricing ($0.62), its slightly lower on-time delivery rate (93%) warrants closer logistics coordination for time-sensitive campaigns.

FAQs

How to verify Scotch ice cube maker supplier credibility?

Validate certifications for food contact materials (LFGB, FDA) and electrical safety (CE, CCC) where applicable. Request test reports for thermal stability and cycle durability, especially for commercial compressors. Review transaction history through trade assurance programs and confirm consistency in delivery performance across multiple order sizes.

What is the typical lead time for bulk orders?

Standard commercial ice machines require 30–45 days for production and pre-shipment inspection. Silicone mold batches (100–1,000 units) can be fulfilled within 15–25 days. Expedited production may reduce timelines by 7–10 days at an additional cost.

Can suppliers accommodate small trial orders?

Yes, most silicone mold manufacturers accept single-piece samples or trial runs of 50–100 units. Some waive sample fees if followed by a confirmed bulk order. Industrial ice machine suppliers typically require full payment even for single-set trials due to high component costs.

Are there minimum order quantity (MOQ) flexibilities?

MOQs are negotiable, especially for repeat buyers. Mold suppliers often reduce MOQs for long-term contracts or bundled purchases. Commercial ice machine vendors may allow container mixed-load shipments to help smaller distributors consolidate orders.

What customization options are available for branding?

Full branding support includes logo embossing, custom packaging inserts, multilingual labels, and unique mold cavity designs (e.g., spherical "whiskey stones"). Suppliers with dedicated R&D teams can develop proprietary shapes and release mechanisms within 3–6 weeks from concept approval.