Whiskey Ice Cube Maker

CN

CN

Top sponsor listing

Top sponsor listing

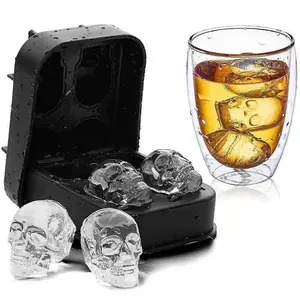

About whiskey ice cube maker

Where to Find Whiskey Ice Cube Maker Suppliers?

China serves as the primary manufacturing hub for whiskey ice cube makers, with key production clusters in Guangdong and Fujian provinces. Shenzhen and Guangzhou-based suppliers dominate silicone and plastic mold fabrication, leveraging mature polymer processing infrastructure and proximity to ports for efficient export logistics. Xiamen-based manufacturers specialize in premium metal cooling solutions, including stainless steel and titanium ice cubes, benefiting from regional expertise in precision metal forming and surface treatment technologies.

These industrial zones support vertically integrated supply chains—from raw material compounding to injection molding and packaging—enabling rapid prototyping and scalable production. Suppliers typically operate semi-automated assembly lines capable of producing 50,000–200,000 units per month, depending on complexity. The concentration of tooling workshops and material vendors within 50km radii reduces component lead times by 15–25%, while shared logistics networks lower freight costs for international buyers. Common materials include food-grade silicone (FDA 21 CFR 177.2600 compliant), BPA-free polypropylene, and medical-grade stainless steel (304/316).

How to Choose Whiskey Ice Cube Maker Suppliers?

Procurement decisions should be guided by objective evaluation criteria to ensure product quality, compliance, and operational reliability.

Material & Safety Compliance

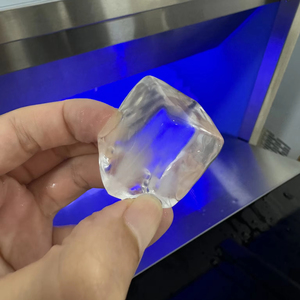

Verify that all contact materials meet food safety standards: FDA, LFGB, or EU Regulation (EC) No 1935/2004. For silicone molds, confirm Shore A hardness ratings between 40–60 for optimal flexibility and durability. Metal cooling products must undergo passivation treatment and comply with RoHS directives. Request test reports from accredited laboratories for heavy metals, migration, and thermal stability (−20°C to 100°C).

Production and Customization Capability

Assess supplier capacity based on the following benchmarks:

- Minimum facility size of 2,000m² for consistent batch output

- In-house mold design and CNC tooling capabilities

- Customization scope covering shape (sphere, cube, prism), color (Pantone matching), size (30–80mm diameter), packaging (private label, blister cards), and branding (embossing, laser engraving)

Prioritize suppliers offering vacuum sealing and leak-testing protocols for liquid-filled metal cubes.

Order Fulfillment Metrics

Analyze performance indicators such as on-time delivery rate (>95%), reorder rate (>15%), and response time (<4 hours). Cross-reference these metrics with order volume thresholds—suppliers with online revenue exceeding US $250,000 annually demonstrate proven export experience. Confirm MOQs are negotiable, particularly for customized runs; standard silicone molds often require 50–100 pieces, while metal variants may require 500+ units.

What Are the Best Whiskey Ice Cube Maker Suppliers?

| Company Name | Location | Main Materials | Product Range | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kean Silicone Baby Product Co., Ltd. | Shenzhen, CN | Silicone, Plastic | Silicone molds, clear ice trays, large cavity spheres | 100% | ≤2h | US $180,000+ | 18% | Color, size, logo, packaging, material grade |

| Shenzhen Huilian Xing Technology Co., Ltd. | Shenzhen, CN | Silicone, Plastic | 3D ice trays, novelty sphere makers, food-grade molds | 98% | ≤2h | US $290,000+ | 16% | Color, size, logo, packaging, graphic design |

| Xiamen Theone Household Products Co., Ltd. | Xiamen, CN | Stainless Steel, Titanium, Silicone | Metal cooling cubes, BPA-free reusable molds | 98% | ≤2h | US $10,000+ | <15% | Shape, material, finish, size, private labeling |

| Guangzhou Raybin Homewares Co., Ltd. | Guangzhou, CN | Silicone, Plastic | Grid-style trays, portable ball makers, reusable molds | 92% | ≤2h | US $590,000+ | 26% | Color, material, size, logo, packaging, graphics |

| Protecting Your Electronics (pye) Electronic Technology Co., Ltd. | Shenzhen, CN | Plastic, Silicone | Ice ball molds, multi-grid trays, vacuum-sealed designs | 92% | ≤4h | US $130,000+ | 19% | Lid type, weight, packaging, label print, mold design |

Performance Analysis

Shenzhen-based suppliers exhibit strong technical control, with two achieving 98–100% on-time delivery rates, indicating robust production planning. Guangzhou Raybin leads in customer retention (26% reorder rate), reflecting consistent quality and service responsiveness. While Xiamen Theone has a lower reported reorder rate, its specialization in high-value metal cooling products suggests niche market positioning rather than performance deficiency. Suppliers in Shenzhen demonstrate broader customization depth, particularly in mold engineering and vacuum sealing—a critical advantage for branded or premium-tier offerings. Buyers seeking high-volume silicone production should prioritize Shenzhen Kean or Huilian Xing, whereas those requiring metal alternatives should evaluate Xiamen Theone’s titanium and stainless steel casting capabilities.

FAQs

How to verify whiskey ice cube maker material safety?

Request compliance documentation for FDA, LFGB, or EU 1935/2004 standards. For silicone, validate Shore A hardness and elongation at break (≥150%). Metal components should provide mill test certificates confirming ASTM A276/A484 compliance for stainless steel or ASTM B261 for titanium.

What is the typical lead time for bulk orders?

Standard silicone mold orders (MOQ 100–1,000 pcs) take 15–25 days for production, plus 5–10 days for air freight. Custom tooling extends timelines by 7–14 days. Metal cube production requires 20–30 days due to machining and passivation processes.

Can suppliers provide free samples?

Most suppliers offer paid samples ($0.20–$13.63/unit) applicable toward first orders. Free samples are rare but negotiable for contracts exceeding 1,000 units. Expect 5–15 days for sample dispatch, including custom configurations.

Are private labeling and OEM packaging available?

Yes, all listed suppliers support private labeling, including custom box design, UPC coding, and multilingual inserts. Minimum branding quantities vary: 100 units for silicone molds, 500+ for metal products. Logo application methods include pad printing, embossing, and laser etching.

What are common MOQs and pricing ranges?

MOQs range from 50 pieces (silicone molds) to 500 pieces (metal cubes). Unit prices vary by material: silicone molds ($0.39–$2.13), plastic trays ($0.25–$1.87), and metal cooling cubes ($0.20–$13.63/set). Volume discounts typically apply at 1,000+ units.