Segment Lcd Display Manufacturers

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/29

1/29

0

0

1/3

1/3

1/1

1/1

1/3

1/3

1/37

1/37

1/38

1/38

1/3

1/3

1/3

1/3

1/54

1/54

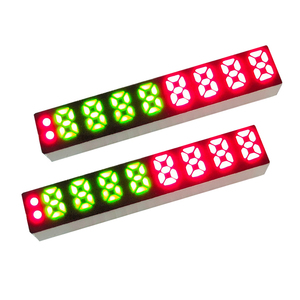

About segment lcd display manufacturers

Where to Find Segment LCD Display Manufacturers?

China remains the global epicenter for segment LCD display manufacturing, with key production hubs concentrated in Guangdong and Dongguan. These regions host vertically integrated supply chains that streamline access to raw materials such as glass substrates, polarizers, and driver ICs, enabling rapid prototyping and high-volume production. The proximity of component suppliers, assembly lines, and logistics networks reduces lead times by up to 30% compared to offshore alternatives.

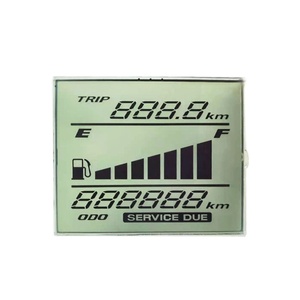

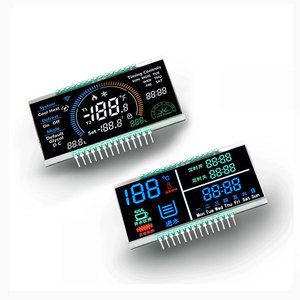

Manufacturers in Shenzhen and Dongguan specialize in custom segment displays for consumer electronics, industrial instrumentation, and medical devices. Facilities typically feature automated bonding, sealing, and testing lines capable of producing TN, HTN, STN, and VA-type monochrome LCDs. With average factory areas exceeding 1,500m² and monthly output capacities ranging from 100,000 to over 1 million units, these suppliers support both low-volume development runs and large-scale deployments.

How to Choose Segment LCD Display Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities

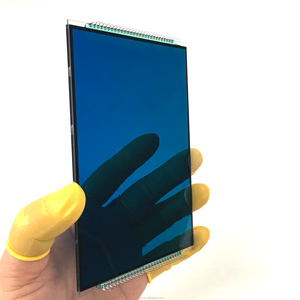

Confirm expertise in segment LCD design and fabrication processes, including photomask development, ITO etching, and liquid crystal injection. Prioritize suppliers offering full customization—from segment layout and viewing angle (transmissive, reflective, transflective) to backlighting (LED, electroluminescent). Material specifications should include operating temperature ranges (-20°C to +70°C standard), contrast ratios (>4:1), and response times (<300ms).

Production & Quality Assurance

Evaluate infrastructure based on the following benchmarks:

- In-house tooling and mold-making capabilities for custom designs

- Dedicated cleanroom environments for display assembly

- Automated optical inspection (AOI) and electrical testing protocols

Verify compliance with international standards such as ISO 9001, RoHS, and REACH. While not always explicitly stated, adherence to these frameworks is standard among established manufacturers serving export markets.

Order Flexibility and Transaction Metrics

Assess scalability through minimum order quantity (MOQ) thresholds and pricing structures. MOQs vary significantly—from 1 piece for prototypes to 2,000+ units for cost-optimized production. Lead times typically range from 15–30 days post-design approval. Favor suppliers with proven on-time delivery records (≥98%) and fast response times (≤2 hours) to ensure project continuity.

What Are the Top Segment LCD Display Manufacturers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Sample MOQ | Unit Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Dongguan Hongqi Optoelectronics Technology Co., Ltd. | EL Products (121) Segment Displays (64) | US $200+ | 100% | ≤2h | <15% | 10 pcs | N/A |

| Guangdong SCCdisplay Technology Co.,Ltd. | LCD Modules (868) OLED/E-Paper (66) | US $70,000+ | 100% | ≤1h | 42% | 2 pcs | $1.39–5.00 |

| Shenzhen Zhongheda Technology Co., Ltd. | LCD Modules (236) OLED/E-Paper (112) | US $30,000+ | 100% | ≤2h | <15% | 1 pc | $1.60–21.70 |

| Shenzhen Detone Technology Co., Ltd. | LCD Modules (168) Segment Displays (13) | US $10,000+ | 100% | ≤3h | <15% | 1 pc | $0.10–0.20 |

| Shenzhen Guangjinda Electronics Co., Ltd. | LCD Modules (120) Segment Displays (6) | US $10,000+ | 100% | ≤1h | <15% | 2 pcs | $0.10–2.00 |

Performance Analysis

Guangdong SCCdisplay stands out with a 42% reorder rate and sub-one-hour response time, indicating strong customer satisfaction and operational efficiency. Shenzhen Detone and Guangjinda offer the lowest unit pricing ($0.10–$0.20), ideal for high-volume applications requiring cost-sensitive components. Dongguan Hongqi focuses heavily on segment-specific production, evidenced by its dedicated product listings, though transaction volume suggests a niche market presence. All listed suppliers maintain perfect on-time delivery performance, a critical factor for just-in-time manufacturing environments.

FAQs

How to verify segment LCD display manufacturer reliability?

Cross-check self-reported capabilities with product documentation, including datasheets, test reports, and material declarations. Request references or case studies for similar projects. Evaluate responsiveness and technical clarity during initial inquiries as proxies for long-term communication quality.

What is the typical sampling timeline for custom segment LCDs?

Prototype development generally takes 10–20 days after finalizing design files (Gerber or CAD formats). Additional time may be required for mask creation and environmental testing. Air shipping adds 5–10 days for international delivery.

Can manufacturers produce small-batch or prototype orders?

Yes, multiple suppliers accept orders as low as 1–2 pieces for evaluation. Unit costs are higher at low volumes but decrease significantly beyond 1,000–2,000 units due to economies of scale in tooling and setup.

Do suppliers support design customization?

All listed manufacturers offer full customization, including segment count, digit configuration, pin layout, and mounting options. Most provide free design review services and can generate updated specifications within 48 hours of receiving technical requirements.

What are common payment and logistics terms?

Standard payment methods include T/T and L/C, with sample fees often required upfront. Bulk orders typically involve 30% deposit and 70% before shipment. FOB Shenzhen or Guangzhou is standard; CIF terms are available upon request. Express shipping (DHL, FedEx) delivers samples in 3–7 days, while sea freight takes 20–35 days for full container loads.