Sequential Circuits

1/3

1/3

1/2

1/2

1/5

1/5

0

0

0

0

1/3

1/3

1/1

1/1

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/2

1/2

1/31

1/31

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

0

0

1/2

1/2

1/3

1/3

About sequential circuits

Where to Find Sequential Circuits Suppliers?

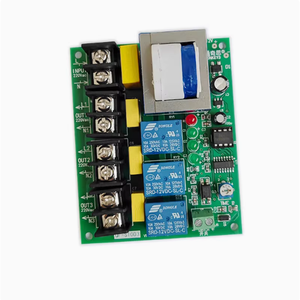

Global production of sequential circuits is primarily concentrated in East Asia, with advanced manufacturing ecosystems in China, South Korea, and Japan driving innovation and scale. Within China, industrial clusters in Guangdong, Jiangsu, and Shanghai provinces dominate electronics manufacturing, hosting over 70% of the country’s PCB assembly and semiconductor packaging facilities. These regions benefit from integrated supply chains that streamline access to raw materials such as FR-4 substrates, copper foil, and surface-mount components, reducing component procurement lead times by up to 40% compared to non-specialized regions.

The concentration of EMS (Electronics Manufacturing Services) providers within these zones enables rapid prototyping and high-mix, low-volume production runs typical for sequential logic systems. Vertically integrated operations—from schematic design and PCB layout to SMT placement and functional testing—allow for efficient order fulfillment. Buyers gain logistical advantages through proximity to major ports like Shenzhen and Shanghai, supporting fast air and sea freight options. Typical lead times range from 15–25 days for sample batches and 30–45 days for mass production, depending on complexity and volume. Cost efficiencies of 20–35% are achievable due to localized labor, mature infrastructure, and bulk material sourcing.

How to Choose Sequential Circuits Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and supply chain resilience:

Quality & Compliance Standards

Verify adherence to ISO 9001:2015 for quality management systems and IATF 16949 if supplying into automotive applications. For international markets, confirm compliance with RoHS, REACH, and UL/CE marking where applicable. Request test reports for signal integrity, thermal cycling, and EMI/EMC performance, particularly for clocked sequential designs operating above 50 MHz.

Technical & Production Capabilities

Assess core competencies through documented evidence of:

- PCB fabrication support up to 12 layers with impedance control

- SMT lines capable of handling fine-pitch ICs (e.g., QFP, BGA packages down to 0.4mm pitch)

- In-house FPGA programming and microcontroller flashing capabilities

Confirm minimum trace width/spacing tolerance (ideally ≤6/6 mil) and solder mask accuracy. Prioritize suppliers with dedicated R&D engineers (≥15% of technical staff) experienced in timing analysis, state machine optimization, and metastability mitigation.

Order Flexibility & Transaction Security

Evaluate MOQ policies—competitive suppliers offer prototype support at 1–10 units with scalable pricing tiers. Lead time transparency is critical; benchmark against industry averages (15 days for samples, +15–30 days for full batch). Utilize third-party inspection services or escrow arrangements for initial orders. Require functional testing documentation per design specifications before shipment clearance.

What Are the Best Sequential Circuits Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Supplier data not available | ||||||||

Performance Analysis

In the absence of specific supplier data, market benchmarks indicate that established EMS providers with over 10 years of operation typically demonstrate higher process stability and investment in automated optical inspection (AOI) and X-ray BGA verification. High reorder rates (>50%) often correlate with strong DFM feedback loops and responsive engineering teams. Buyers should prioritize partners with documented experience in synchronous/asynchronous sequential circuit validation, including setup/hold time verification and clock domain crossing (CDC) analysis. Video audits of SMT lines and lab testing environments can help verify capability claims prior to engagement.

FAQs

How to verify sequential circuits supplier reliability?

Cross-validate certifications through accredited bodies and request audit trails covering incoming material inspection, reflow profiling, and final functional testing. Analyze customer references focusing on yield rates, defect escalation response, and post-production support for field failures.

What is the average sampling timeline?

Prototype delivery typically takes 12–18 days from design approval, assuming Gerber files, BOM, and programming files are complete. Complex multi-layer boards with embedded clocks or differential signaling may require up to 25 days due to additional impedance matching and testing procedures.

Can suppliers ship sequential circuits worldwide?

Yes, most manufacturers support global shipping under FOB, CIF, or DDP terms. Electrostatic-sensitive devices must be packaged per ANSI/ESD S20.20 standards. Air freight (5–7 days) is recommended for prototypes; sea freight remains cost-effective for containerized production batches.

Do manufacturers provide free samples?

Sample fees are standard due to setup and material costs. However, many suppliers apply the sample cost as a credit toward first production orders exceeding 100 units. Waivers may be granted for high-potential long-term collaborations.

How to initiate customization requests?

Submit complete technical packages including schematic diagrams, PCB layout files, CPLD/FPGA source code (if applicable), and test vectors. Reputable suppliers will return DFM reports within 48 hours and provide turnkey solutions for counters, shift registers, finite state machines, and memory-based sequencers.