Servo Stabilizer With Isolation Transformer

TR

TR

About servo stabilizer with isolation transformer

Where to Find Servo Stabilizer with Isolation Transformer Suppliers?

China remains the central hub for manufacturing servo stabilizers integrated with isolation transformers, driven by concentrated industrial zones in Zhejiang, Anhui, and Guangdong provinces. These regions host specialized electrical equipment clusters where suppliers leverage vertically integrated production ecosystems—from copper coil winding and core lamination to final assembly—enabling rapid prototyping and scalable output. Zhejiang and Guangdong are particularly notable for their high-density networks of component suppliers, reducing lead times by up to 25% compared to decentralized manufacturing bases.

Suppliers in these clusters benefit from access to raw materials such as grain-oriented silicon steel, electrolytic copper, and insulating resins, ensuring consistent material traceability and cost efficiency. The average facility operates within a 5,000–10,000m² footprint, supporting batch production capacities ranging from 500 to 2,000 units per month depending on kVA rating. This infrastructure enables competitive pricing structures, with single-phase models starting at $70 and three-phase industrial-grade units exceeding $5,000 for high-capacity configurations (up to 500kVA).

How to Choose Servo Stabilizer with Isolation Transformer Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Expertise

Verify adherence to international standards including CE, IEC 61558, and RoHS. For critical applications in healthcare, data centers, or industrial automation, confirm design integration between the servo-controlled voltage regulation system and the isolation transformer’s dielectric insulation (typically rated at 3kV AC for 1 minute). Assess whether the supplier specifies key parameters such as voltage regulation accuracy (±1–3%), response time (<10ms), and temperature rise limits (≤60°C).

Production Capability Verification

Prioritize manufacturers demonstrating in-house control over core processes:

- Automated coil winding and vacuum pressure impregnation (VPI) lines

- On-site testing labs capable of performing hipot, no-load current, and short-circuit impedance tests

- Customization capacity for input/output voltages (e.g., 220V/380V/480V), frequency (50/60Hz), and enclosure types (IP20–IP55)

Cross-reference declared capabilities with verified performance metrics such as on-time delivery rates (>97%) and reorder frequency.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms that align with order milestones, especially for custom-built units. Evaluate suppliers based on documented quality management systems; those with ISO 9001 certification demonstrate structured QC protocols. Request test reports for sample units, including waveform stability under fluctuating loads and harmonic distortion levels. Conduct remote audits via factory walkthrough videos to validate production line authenticity and inventory readiness.

What Are the Best Servo Stabilizer with Isolation Transformer Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Custom Capabilities | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Anhui Yingk Power Technology Co., Ltd. | Voltage Regulators/Stabilizers, UPS, Low Voltage Transformers | US $10,000+ | 100% | ≤5h | 66% | Standard product range | 1 piece/set | $105–599 |

| Zhejiang Kaiyi Electric Co., Ltd. | Voltage Regulators/Stabilizers, Connectors, ATS, Circuit Breakers | US $30,000+ | 100% | ≤1h | 20% | Low-voltage customization | 5–50 sets | $100–450 |

| Zhejiang Yibaling Technology Co., Ltd. | Servo Stabilizers, Toroidal & Audio Isolation Transformers | US $100,000+ | 100% | ≤1h | 15% | Custom voltage/input designs | 1–5 pieces | $70–2,200 |

| Shenzhen Xingkerong Technology Co., Ltd. | Copper-coil Servo Stabilizers, Step-down Transformers | US $190,000+ | 100% | ≤1h | 18% | Full OEM/ODM support | 1 set | $360–2,700 |

| Shenzhen Funice Electric Co., Ltd. | Voltage Stabilizers, Transformers, UPS, Inverters | US $210,000+ | 100% | ≤2h | 25% | High-power custom builds | 1 unit/set | $179–4,900 |

Performance Analysis

Shenzhen-based suppliers dominate high-power segment availability, offering units up to 500kVA with full copper-wound transformers, while Zhejiang manufacturers excel in low-to-mid range stabilization solutions with fast response times and flexible MOQs. Anhui Yingk stands out with a 66% reorder rate, indicating strong customer retention likely due to balanced pricing and reliable delivery. All listed suppliers maintain 100% on-time delivery records, suggesting robust internal logistics planning. Buyers seeking ODM/OEM partnerships should prioritize Shenzhen Xingkerong and Zhejiang Yibaling, both explicitly noted for advanced customization capabilities. For mission-critical installations requiring certified components, verify inclusion of CE-marked circuitry and flame-retardant enclosures (UL94 V-0).

FAQs

How to verify servo stabilizer and isolation transformer supplier reliability?

Confirm compliance through independent documentation: request copies of CE/IEC test reports, material safety data sheets (MSDS), and factory inspection summaries. Analyze transaction history for consistency in order fulfillment and assess responsiveness patterns—suppliers answering within 2 hours typically exhibit better service discipline.

What is the typical lead time for standard and custom units?

Standard models are generally available within 15–25 days after order confirmation. Custom configurations involving non-standard voltages, special enclosures, or enhanced insulation may require 30–45 days, depending on complexity and component sourcing requirements.

Can suppliers provide units with copper windings instead of aluminum?

Yes, several manufacturers—including Shenzhen Xingkerong and Shenzhen Funice—explicitly offer copper-wound transformers, which improve efficiency, reduce heat generation, and extend service life. Confirm winding material in technical specifications prior to ordering, as this significantly impacts performance and longevity.

Do suppliers support small-volume orders or prototypes?

Most suppliers accept minimum orders of 1–5 units, making them accessible for pilot deployments or testing. Some, like Zhejiang Yibaling, offer samples from $70 for single-phase 1kVA units, facilitating cost-effective evaluation before scaling procurement.

What are common customization options for industrial applications?

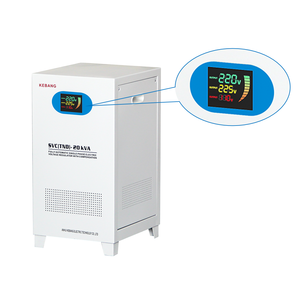

Key configurable parameters include input voltage range (e.g., 170V–260V), output precision (±1%, ±3%), cooling method (air/natural convection), mounting type (wall/din-rail/floor-standing), and protective features (overload, short-circuit, thermal cutoff). High-end models can integrate digital displays, remote monitoring interfaces, and bypass switches.