Servo Voltage Stabilizer Distributor

CN

CN

About servo voltage stabilizer distributor

Where to Find Servo Voltage Stabilizer Distributors?

China remains the central hub for servo voltage stabilizer manufacturing, with key production clusters in Zhejiang, Anhui, and Shanghai driving export-oriented supply. These regions host vertically integrated facilities specializing in power regulation equipment, leveraging localized access to copper, silicon steel, and electronic components. Proximity to major ports such as Ningbo and Shanghai enables efficient global distribution, reducing logistics lead times by 10–15% compared to inland competitors.

The industrial ecosystem supports both high-volume standard production and low-volume customization. Manufacturers typically operate automated winding lines, CNC panel fabrication, and final assembly under ISO-controlled environments. Average monthly output across verified suppliers ranges from 5,000 to 20,000 units, depending on phase configuration (single or three-phase) and kVA capacity. Buyers benefit from scalable production models capable of fulfilling orders from 1 piece to full-container loads within standardized lead times of 15–30 days.

How to Choose Servo Voltage Stabilizer Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

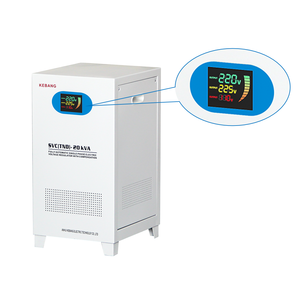

Verify adherence to international electrical safety standards, including IEC 61558 and CE marking for European markets. Suppliers should provide test reports covering dielectric strength, output voltage accuracy (±1–3%), and response time (typically 10–50ms). Look for evidence of pure copper coil usage, which enhances thermal stability and efficiency over aluminum alternatives.

Production and Customization Capability

Assess supplier infrastructure through available indicators:

- Minimum facility size supporting dedicated R&D and QC zones

- In-house transformer winding and PCB assembly lines

- Customization options for input/output voltage range, kVA rating, enclosure type (wall-mounted, desktop, industrial cabinet), and branding (logo, packaging)

- Material flexibility (copper vs. aluminum windings, IP-rated enclosures)

Cross-reference stated capabilities with online revenue metrics and reorder rates—suppliers with consistent repurchase activity (>15%) often demonstrate product reliability and service consistency.

Transaction Reliability & Risk Mitigation

Prioritize suppliers with documented on-time delivery performance (target ≥94%) and sub-4-hour average response times. Evaluate minimum order quantity (MOQ) flexibility—some suppliers offer single-unit sampling, while others require 5–50 pieces. Use secure payment methods and request pre-shipment inspection rights. Confirm packaging durability for long-distance shipping, especially for high-kVA models exceeding 30kg.

What Are the Leading Servo Voltage Stabilizer Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Product Range |

|---|---|---|---|---|---|---|---|---|

| Anhui Pinkong Energy Technology Co., Ltd. | Anhui, CN | Custom Manufacturer | US $160,000+ | 98% | ≤1h | <15% | Color, size, logo, packaging, label | Single & 3-phase, up to 500kVA |

| Zhejiang Kepai Electrical Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $80,000+ | 94% | ≤2h | <15% | Color, material, size, logo, packaging, graphic | SVC series, 1–10kVA, single-phase |

| Quzhou Sanyuan Huineng Electronic Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $140,000+ | 100% | ≤4h | 16% | Color, material, size, logo, packaging, graphic | SVC/SVD series, 1–3kVA, industrial & AC use |

| Zhejiang Sanke New Energy Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $1,400,000+ | 100% | ≤1h | <15% | Color, material, size, logo, packaging, graphic | SVC-N series, 500VA–10kVA, wall-mounted & desktop |

| Shanghai Diansi Electric Co., Ltd. | Shanghai, CN | Custom Manufacturer | US $30,000+ | 92% | ≤7h | 15% | Breaker, color, phase, kVA, material, logo, packaging | Single & three-phase, 2kVA–50kVA |

Performance Analysis

Zhejiang Sanke New Energy stands out with the highest reported online revenue (US $1.4M+) and perfect on-time delivery (100%), supported by rapid ≤1h response times. The company demonstrates strong scalability for bulk procurement across single-phase models. Anhui Pinkong offers high-capacity solutions up to 500kVA, suitable for industrial clients requiring robust three-phase stabilization. Quzhou Sanyuan Huineng achieves a notable 16% reorder rate—the highest in the dataset—indicating customer satisfaction despite longer response windows. Shanghai Diansi provides broad customization depth, including control system and coil material specifications, though its lower revenue suggests niche market positioning. Buyers seeking fast turnaround and proven volume capacity should prioritize suppliers with 100% on-time delivery and sub-2h response benchmarks.

FAQs

What is the typical MOQ for servo voltage stabilizers?

MOQ varies by supplier and model. Some manufacturers allow single-piece orders for sampling, while others require 5–50 units for standard configurations. High-kVA industrial units may carry higher MOQs based on production scheduling.

How long does production and shipping take?

Lead time averages 15–25 days for production, plus 7–14 days for international air freight or 25–40 days via sea shipment. Express courier services can deliver samples within 5–7 days.

Can servo stabilizers be customized for specific voltage ranges?

Yes, most suppliers support input voltage customization (e.g., 80V–260V) and output precision tuning. Custom kVA ratings, frequency (50/60Hz), and mounting styles are commonly available upon request.

Do suppliers provide certifications for export compliance?

While not all list formal ISO or CE documentation publicly, leading suppliers design products to meet international safety norms. Buyers should explicitly request compliance certificates and conduct third-party testing when importing into regulated markets.

What materials are used in core components?

Top-tier models use pure copper windings for enhanced conductivity and heat resistance. Lower-cost variants may use aluminum or copper-clad aluminum. Confirm material specifications directly with the supplier to ensure longevity under continuous load.