Siemens Cnc System

CN

CN

CN

CN

About siemens cnc system

Where to Find Siemens CNC System Suppliers?

China remains a central hub for industrial automation and CNC machinery manufacturing, with key supplier clusters in Shandong, Beijing, and Zhejiang provinces. These regions host vertically integrated facilities specializing in precision machining systems powered by Siemens controls. Shandong’s Jinan and Qingdao zones are recognized for high-volume production of CNC vertical and horizontal machining centers, supported by mature metalworking supply chains. Beijing-based suppliers focus on high-end 5-axis systems and automation integration, leveraging proximity to R&D institutions and export logistics networks. Zhejiang’s Jiaxing region specializes in electrical control components, including standalone Siemens CNC modules and retrofit solutions.

The geographic concentration enables efficient access to casting, milling, heat treatment, and assembly services within compact industrial ecosystems. This integration supports lead times averaging 45–60 days for standard configurations, with cost advantages of 20–35% over European or North American manufacturers. Buyers benefit from scalable production capacity, modular design frameworks, and established export channels serving automotive, aerospace, and mold-making industries.

How to Choose Siemens CNC System Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

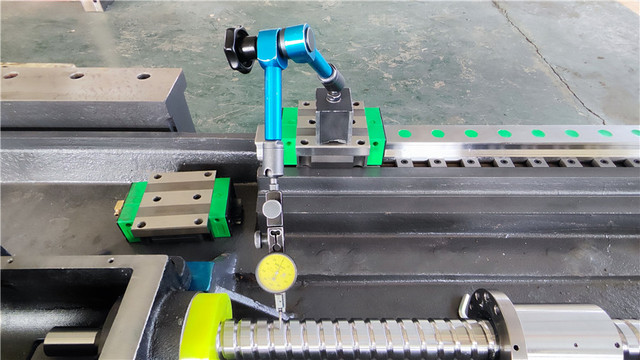

Confirm compatibility with Siemens control series such as 808D, 828D, and 840D through product specifications and firmware documentation. For full-machine integrations, validate machine tool rigidity, spindle accuracy (±0.005mm typical), and axis positioning repeatability. Request test reports on dynamic performance metrics like thermal stability and vibration damping, particularly for 5-axis applications.

Production Infrastructure Assessment

Evaluate the following indicators of manufacturing maturity:

- Minimum factory footprint of 3,000m² for comprehensive machining and assembly lines

- In-house engineering teams capable of customizing work envelopes, pallet systems, or Siemens HMI interfaces

- Integration of FEM analysis and laser calibration in quality assurance protocols

Cross-reference delivery performance (target ≥97%) with order volume history to assess scalability and resource allocation.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as escrow services until equipment passes site commissioning. Prioritize suppliers with verifiable export experience and third-party trade assurances. Conduct pre-shipment inspections to verify mechanical alignment, control software version, and safety interlock functionality. Sample testing is recommended—run benchmark cycles using ISO 230-2 standards to evaluate geometric accuracy before bulk procurement.

What Are the Best Siemens CNC System Suppliers?

| Company Name | Location | Core Products | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization | Product Range |

|---|---|---|---|---|---|---|---|---|

| Beijing Deraya Technology Co., Ltd. | Beijing, CN | 5-Axis Vertical & Horizontal CNC Centers | 100.0% | ≤2h | Not disclosed | Not available | Color, material, logo, packaging, graphics | $114K–$340K |

| Shandong Weste Cnc Machine Tool Co., Ltd. | Shandong, CN | VMC Series Machining Centers, Milling Machines | 100.0% | ≤3h | US $30,000+ | 100% | Not specified | $7.5K–$28.8K |

| Jinan Hongda Cnc Equipment Co., Ltd. | Shandong, CN | CNC Lathes, VMC850/855, 5-Axis Mills | 100.0% | ≤2h | US $950,000+ | 30% | Not specified | $5.8K–$18K |

| Jiaxing Shengda Automation Technology Co.,Ltd | Zhejiang, CN | Siemens 808D/828D/840D Control Systems, Software Modules | 100.0% | ≤2h | US $9,000+ | <15% | Not specified | $120–$1,680 (per dozen) |

| Yuxi Hengyao Machinery Co., Ltd. | Yunnan, CN | 5-Axis Vertical Machining Centers, GX800 Series | 100.0% | ≤6h | Not disclosed | Not available | Not specified | $140K–$350K |

Performance Analysis

Beijing Deraya and Yuxi Hengyao specialize in premium 5-axis machining systems with prices reflecting advanced kinematics and structural optimization. Shandong Weste and Jinan Hongda offer competitive mid-range solutions ideal for general-purpose machining, supported by strong reorder rates indicating customer satisfaction. Jiaxing Shengda stands out as a component-level supplier, providing authentic Siemens CNC control units suitable for retrofits or OEM integration. All listed suppliers maintain 100% on-time delivery records, though response speed varies, with Beijing and Shandong-based firms offering sub-3-hour average reply times. Suppliers with higher online revenue (e.g., Jinan Hongda) demonstrate consistent market presence and export activity.

FAQs

How to verify Siemens CNC system supplier reliability?

Validate technical claims through direct inspection of control unit model numbers (e.g., 6FC5370-1AT00 for 808D). Request documentation on software licensing, backup procedures, and diagnostic capabilities. Cross-check company registration details and review transaction histories for dispute patterns. Third-party audits or video walkthroughs of assembly and testing processes add verification depth.

What is the typical lead time for Siemens-integrated CNC machines?

Standard configurations require 45–60 days from order confirmation to shipment. Customized systems with extended axes, automated loading, or specialized coolant management may extend to 75–90 days. Component-level CNC controls (e.g., 828D units) typically ship within 15–25 days.

Do suppliers support global shipping and installation?

Yes, most suppliers coordinate international freight via sea or air depending on equipment size. FOB terms are common; CIF can be arranged upon request. Some providers offer optional technician dispatch for commissioning and operator training, typically at additional cost. Ensure compliance with local electrical and safety codes prior to installation.

Can I request customization on Siemens CNC machines?

Yes, leading suppliers support modifications including worktable dimensions, tool magazine capacity, probing systems, and Siemens Operate interface localization. Structural changes require engineering validation. Beijing Deraya explicitly lists customization options for color, materials, logos, and packaging—ideal for private-label or industry-specific branding.

What are the minimum order quantities (MOQ)?

For complete CNC machines, MOQ is typically 1 set. For control system components (e.g., Siemens 808D), MOQ is often sold per dozen units. Negotiation for lower quantities may be possible during sample phases or for long-term contracts.