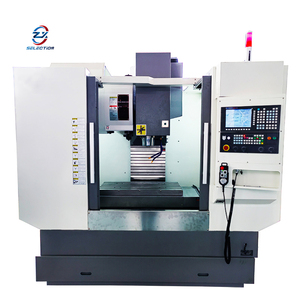

Small 3 Axis Cnc Milling Machine

About small 3 axis cnc milling machine

Where to Find Small 3-Axis CNC Milling Machine Suppliers?

China remains the global epicenter for small 3-axis CNC milling machine production, with key manufacturing clusters concentrated in Shandong and Jiangsu provinces. These regions host vertically integrated supply chains encompassing casting, precision machining, control system integration, and final assembly—all within tightly coordinated industrial zones. Shandong’s Jining and Zaozhuang hubs specialize in mid-sized vertical machining centers (VMCs), leveraging proximity to steel suppliers and port infrastructure to reduce logistics costs by 15–20% compared to non-Asian manufacturers.

The ecosystem supports scalable production, enabling suppliers to fulfill both low-volume prototyping orders and bulk procurement contracts efficiently. Buyers benefit from localized component sourcing—linear guides, ball screws, spindles, and CNC controllers—sourced from domestic Tier-1 vendors, which contributes to lead times averaging 30–45 days for standard configurations. Cost efficiencies are further amplified by modular designs that allow rapid reconfiguration across models, supporting customization without significant tooling investment.

How to Choose Small 3-Axis CNC Milling Machine Suppliers?

Procurement decisions should be guided by structured supplier evaluation criteria:

Technical Compliance

Confirm adherence to international safety and performance standards such as CE marking, ISO 9001 quality management, and EMC directives. For export markets, verify inclusion of compliant electrical cabinets, emergency stop circuits, and operator protection systems. Request documentation on spindle runout tolerance (typically ≤0.005mm), positioning accuracy (±0.01mm), and repeatability metrics.

Production Capability Verification

Assess operational scale and technical maturity through verifiable indicators:

- Facility size exceeding 3,000m² indicating volume capacity

- In-house assembly lines with dedicated testing stations

- Integration of Mach3, Syntec, or Siemens control systems

Cross-reference delivery performance (target ≥95%) and response time (ideally ≤2 hours) as proxies for organizational efficiency and customer service infrastructure.

Transaction Risk Mitigation

Utilize secure payment mechanisms such as trade assurance or escrow services until post-delivery inspection is completed. Prioritize suppliers with transparent revenue reporting and reorder rates above 20%, signaling product reliability and after-sales support effectiveness. Conduct pre-shipment inspections to validate machine calibration, lubrication systems, and tool changer functionality where applicable.

What Are the Best Small 3-Axis CNC Milling Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Shandong Dehai Yaoyang Cnc Machine Tool Co., Ltd. | Shandong, CN | US $380,000+ | 75% | ≤1h | <15% | 5 | $9,700–14,900 | 1 set |

| Changzhou Handi Motor Science And Technology Co., Ltd. | Jiangsu, CN | US $40,000+ | 100% | ≤3h | <15% | 5 | $490–920 | 1 piece |

| Hengshui Mengshang Trading Co., Ltd. | Hebei, CN | US $220,000+ | 100% | ≤2h | 22% | 5 | $58–378 | 1 piece |

| Shandong Lu Young Machinery Co., Ltd. | Shandong, CN | US $110,000+ | 100% | ≤2h | 40% | 5 | $6,800–21,500 | 1 set |

| Shandong Taimeng Cnc Machine Tool Co., Ltd. | Shandong, CN | US $10,000+ | 100% | ≤3h | - | 5 | $5,700–12,500 | 1 set |

Performance Analysis

Shandong-based manufacturers dominate higher-end segments, offering full-scale VMCs priced between $6,800 and $21,500 with structural cast iron frames and industrial-grade spindles. Shandong Lu Young Machinery stands out with a 40% reorder rate, indicating strong customer retention likely driven by customization capabilities such as automatic tool changers and thermal stabilization systems. In contrast, Jiangsu and Hebei suppliers focus on compact desktop and benchtop units targeting hobbyists, PCB fabrication, and light metal engraving, with prices starting under $100. While these lower-cost models offer accessibility, they typically lack hardened ways and high-torque spindles required for continuous production use. Buyers seeking industrial durability should prioritize suppliers with documented engineering teams and verified facility operations over drop-shipped or trading-only entities.

FAQs

How to verify small 3-axis CNC milling machine supplier reliability?

Validate certifications through issuing bodies and request factory audit reports or video walkthroughs of assembly processes. Analyze transaction history, focusing on consistent on-time delivery (>95%), responsive communication, and verifiable post-sale service records. Third-party inspection services can confirm machine build quality before shipment.

What is the typical lead time for custom CNC milling machines?

Standard models ship within 30–45 days. Customizations such as upgraded spindles (e.g., 8,000 RPM HSK-E32), coolant systems, or specialized workholding extend lead times to 60 days. Prototypes or modified control interfaces may require up to 8 weeks depending on complexity.

Can suppliers accommodate OEM branding and technical modifications?

Yes, many manufacturers offer OEM labeling, interface localization, and mechanical adjustments including table size, travel range, and motor power. Technical specifications must be submitted in CAD or detailed schematics for feasibility review. Lead time increases proportionally with design deviation from standard models.

Do small CNC milling machines come with software and training support?

Most suppliers bundle basic CAM compatibility (e.g., compatibility with Mastercam, Fusion 360, or UGS) and provide operation manuals, wiring diagrams, and instructional videos. Advanced training, including maintenance protocols and troubleshooting, is often available via remote sessions or on-site visits at additional cost.

What are common packaging and shipping methods?

Machines are typically crated in seaworthy wooden enclosures with foam cushioning and moisture barriers. Full container loads (FCL) are recommended for multiple units to minimize handling risk. Air freight is viable for single units requiring urgent delivery, though costs are significantly higher. Confirm FOB terms and insurance coverage prior to dispatch.