Small Scale Tomato Processing Machine

1/12

1/12

1/15

1/15

1/19

1/19

1/28

1/28

CN

CN

1/20

1/20

1/6

1/6

1/27

1/27

1/14

1/14

1/14

1/14

CN

CN

1/19

1/19

CN

CN

1/13

1/13

1/18

1/18

1/24

1/24

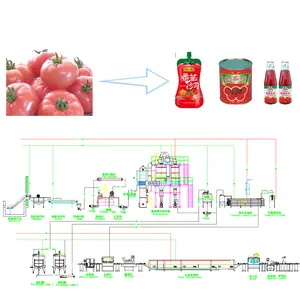

About small scale tomato processing machine

Where to Find Small Scale Tomato Processing Machine Suppliers?

China is the leading global source for small scale tomato processing machines, with key manufacturing clusters concentrated in Henan and Shanghai. These regions host vertically integrated supply chains that support rapid prototyping, cost-efficient production, and scalable customization. Henan alone accounts for over 40% of China’s food processing equipment suppliers, leveraging established industrial ecosystems in Zhengzhou and Xinxiang to deliver standardized and engineered-to-order systems.

The region benefits from proximity to stainless steel foundries, CNC fabrication hubs, and automation component suppliers, reducing material lead times by 20–30%. This integration enables manufacturers to offer complete processing lines—from washing and crushing to pasteurization and packaging—with typical delivery windows of 30–60 days. Buyers gain access to modular designs suitable for capacities ranging from 500 kg/h to 10 tons/day, ideal for startups, regional brands, and contract manufacturers entering the sauce, paste, or ketchup markets.

How to Choose Small Scale Tomato Processing Machine Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international food safety standards such as ISO 22000, CE marking for mechanical and electrical components, and compliance with FDA guidelines for food contact surfaces. Stainless steel construction (preferably SS304 or SS316) must be documented with material test reports. Request validation of critical subsystems including thermal processing controls, homogenization units, and CIP (Clean-in-Place) functionality.

Production Capability Assessment

Evaluate supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² for full-line assembly capability

- In-house engineering team capable of process flow design and automation integration

- Proven experience with turnkey installations and commissioning support

Cross-reference claimed capabilities with on-time delivery performance (target ≥95%) and reorder rates as indicators of customer satisfaction.

Customization & Transaction Safeguards

Confirm availability of customization for voltage (e.g., 220V/380V), language interface, output capacity, and packaging integration. Prioritize suppliers offering third-party inspection options prior to shipment. Use secure payment mechanisms such as escrow services, particularly when engaging newer or unverified entities. Always request sample testing—either physical units or video demonstrations—to validate machine performance under real-world conditions.

What Are the Best Small Scale Tomato Processing Machine Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Price Range (USD) | Key Offerings |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Longer Machinery Co., Ltd. | Henan, CN | - | 100% | ≤2h | - | - | $15,999–$25,999 | Automated ketchup lines, canning-integrated systems |

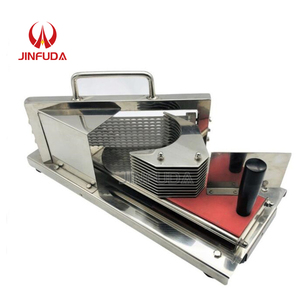

| Henan Jinfuda Trading Co., Ltd. | Henan, CN | Multispecialty Supplier | 98% | ≤3h | <15% | US $570,000+ | $99–$6,000 | Manual slicers, jam cookers, small-scale processors |

| Henan Orange Industry Co.,Ltd. | Henan, CN | Custom Manufacturer | 100% | ≤2h | 19% | US $400,000+ | $13,000–$50,000 | ORME-branded paste/sauce plants, customizable configurations |

| Sss Food Machinery Technology Co., Ltd. | - | - | 100% | ≤3h | - | - | $200,000–$550,000 | High-capacity UHT sterilizers, aseptic packing lines |

| Weishu Machinery Technology (Shanghai) Co., Ltd. | Shanghai, CN | Brand Holder | 92% | ≤4h | 23% | US $480,000+ | $5,200–$72,000 | Compact processing plants, high-productivity paste machines |

Performance Analysis

Suppliers like Zhengzhou Longer Machinery and Sss Food Machinery demonstrate strong execution reliability with 100% on-time delivery, indicating robust production planning. Henan Orange Industry stands out for its custom manufacturing focus, offering scalable solutions within a broad price band ($13K–$50K), supported by responsive communication and moderate reorder activity. Weishu Machinery offers competitively priced entry-level systems starting at $5,200, paired with one of the highest reorder rates (23%), suggesting consistent buyer satisfaction.

Notably, lower-cost offerings from Jinfuda include manual and semi-automatic units (e.g., $99 tomato slicers), which serve niche applications but may lack integration for continuous processing. In contrast, premium-tier suppliers like Sss target industrial-grade operations with investments exceeding $200,000, emphasizing UHT treatment and aseptic filling—critical for shelf-stable products. Buyers should align supplier selection with throughput requirements, automation goals, and long-term scalability.

FAQs

What certifications should tomato processing machine suppliers have?

Ideal suppliers hold ISO 9001 for quality management and CE certification for electrical and mechanical safety. For export to regulated markets, ensure compliance with local food equipment standards such as FDA 21 CFR Part 113 for thermal processing and EC 1935/2004 for food contact materials.

What is the typical MOQ and lead time?

Most suppliers require a minimum order quantity of 1 set, with lead times ranging from 30 to 60 days depending on complexity. Customized lines may extend to 75 days. Expedited builds are possible with additional fees, subject to factory workload.

Can small scale tomato processing machines be customized?

Yes, most manufacturers offer configuration options for capacity, power supply, control panel language, and integration with upstream/downstream equipment. Custom branding, color finishes, and PLC interfaces are commonly available, especially among verified custom manufacturers.

Do suppliers provide installation and training support?

Many suppliers offer remote guidance via video and manuals. On-site commissioning and operator training are typically available at an extra cost, often quoted separately based on technician travel and duration.

How to evaluate machine durability and material quality?

Request material specifications for all wetted parts—ideally SS304 or higher—and verify weld finish quality (e.g., Ra ≤ 0.8 µm for hygienic joints). Ask for pump curves, motor duty ratings, and evidence of pressure testing. Video audits of fabrication processes can help confirm adherence to sanitary design principles.