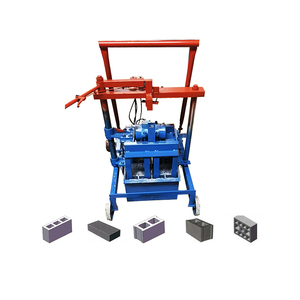

Solid Block Making Machine Distributor

CN

CN

CN

CN

About solid block making machine distributor

Where to Find Solid Block Making Machine Distributors?

China remains the global epicenter for solid block making machine manufacturing, with key industrial hubs concentrated in Henan and Shandong provinces. These regions host vertically integrated production ecosystems that combine casting, machining, and final assembly under one supply chain, enabling cost efficiencies of 20–35% compared to Western or Southeast Asian counterparts. Henan's proximity to major steel producers and logistics corridors supports rapid material procurement and export readiness, while Shandong’s coastal access facilitates containerized shipping to international markets.

The clustering effect allows distributors to offer both standardized models and engineered-to-order systems within compressed timelines. Average lead times range from 20–45 days depending on automation level, with semi-automatic units typically delivered faster than fully automated lines. Suppliers in this sector benefit from mature component networks—hydraulic systems, vibration motors, and mold assemblies are sourced locally, reducing dependency on foreign inputs and enhancing customization agility.

How to Choose Solid Block Making Machine Distributors?

Procurement decisions should be guided by objective evaluation criteria focused on technical capability, transaction reliability, and post-sale support capacity.

Technical Compliance & Certification

Verify adherence to ISO 9001 quality management standards as a baseline indicator of consistent production control. For markets requiring regulatory alignment (EU, USA, GCC), confirm CE marking or equivalent conformity documentation. Request test reports for critical subsystems such as hydraulic pressure performance (typically rated at 18–25 MPa) and mold vibration frequency (standard range: 40–70 Hz).

Production and Customization Capacity

Assess supplier capability through measurable indicators:

- Minimum facility size exceeding 3,000m² for sustained output

- In-house engineering teams capable of modifying mold designs for block type (solid, hollow, paver), dimensions, and compression pressure

- Proven experience in configuring power sources (electric/diesel), feeding systems (manual/automatic), and control panels (PLC-based preferred)

- Customization scope confirmed via documented options: color coding, logo imprinting, pallet-free operation, and mobile configurations

Cross-reference online transaction volume and reorder rates as proxies for market acceptance—suppliers with reorder rates above 25% demonstrate product reliability and service consistency.

Transaction Safeguards and Logistics

Utilize secure payment mechanisms such as third-party escrow services to mitigate risk during initial transactions. Prioritize suppliers with verified delivery performance (target ≥96% on-time rate) and sub-6-hour average response times. Confirm FOB or CIF shipping terms, container loading compatibility (standard 20' or 40' HC), and availability of disassembly/packaging protocols for safe transit. Pre-shipment inspection rights should be contractually secured, especially for orders exceeding $10,000.

What Are the Leading Solid Block Making Machine Distributors?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Gongyi Yuewei Machinery Co., Ltd. | Henan, CN | Brick Making Machinery (221) | US $10,000+ | 100% | ≤2h | 25% | No |

| Henan Daen Industry Co., Ltd. | Henan, CN | Customization Available | US $190,000+ | 96% | ≤2h | 19% | Yes (size, mold, graphic) |

| Linyi Shengming Machinery Co., Ltd. | Shandong, CN | Customization Available | US $530,000+ | 100% | ≤2h | 44% | Yes (color, diesel, capacity, design, mobile, etc.) |

| Qingdao HF Machinery Technology Co., LTD | Shandong, CN | Customization Available | US $130,000+ | 100% | ≤6h | 28% | Yes (color, material, pressure, model, etc.) |

| Shandong Gaotang Huatong Hydraulic Pressure Machinery Co., Ltd. | Shandong, CN | Brick Making Machinery (170) | Not specified | 100% | ≤3h | Not available | No |

Performance Analysis

Linyi Shengming Machinery stands out with the highest reorder rate (44%) and robust customization capabilities across 15+ parameters including hydraulic configuration, block type, and mobility. Its strong revenue performance reflects consistent demand and reliable fulfillment. Gongyi Yuewei and Shandong Gaotang Huatong achieve perfect on-time delivery records but offer limited customization, making them suitable for buyers seeking standard semi-automatic or manual models at competitive prices ($500–$6,000 range). Henan Daen and Qingdao HF provide scalable solutions for specialized applications, though response times vary—Qingdao HF’s ≤6h benchmark may impact urgent project coordination. Buyers prioritizing fast communication should favor suppliers with ≤2h average response windows, particularly when managing cross-border time zones.

FAQs

What is the typical MOQ and pricing range for solid block making machines?

Most suppliers list a minimum order quantity (MOQ) of 1 set or piece. Entry-level mobile models start at $200–$600, semi-automatic units range from $1,400–$7,500, and fully automatic systems exceed $12,500, reaching up to $100,000 for high-capacity German-engineered lines. Pricing correlates directly with automation level, mold complexity, and production output (measured in blocks per hour).

How long does it take to receive a customized machine?

Standard units ship within 20–30 days after order confirmation. Custom-configured machines require an additional 10–25 days depending on design changes, component sourcing, and testing procedures. Complex integrations such as PLC controls or dual-mold systems may extend lead times beyond 45 days.

Can suppliers produce machines for specific block types?

Yes, most established manufacturers can adapt molds for solid concrete blocks, interlocking pavers, hollow bricks, and clay-based units. Custom cavity designs, surface textures, and dimensional specifications (e.g., 400x200x200mm) are commonly supported, provided technical drawings are supplied. Confirm mold fabrication lead time and replacement part availability before finalizing contracts.

Do distributors offer technical support and training?

Leading suppliers include basic operational manuals and wiring diagrams with shipments. Some provide remote video guidance for commissioning; on-site installation and worker training are typically offered as optional paid services, especially for automated lines. Clarify support scope and language proficiency (English-speaking technicians) prior to purchase.

Are spare parts and after-sales service available internationally?

Core wear components—vibration motors, hydraulic seals, and bushings—are generally stocked by suppliers and can be shipped globally. However, long-term service networks depend on local partnerships. Buyers are advised to procure critical spares (e.g., molds, sensors, control boards) alongside initial orders to minimize downtime.