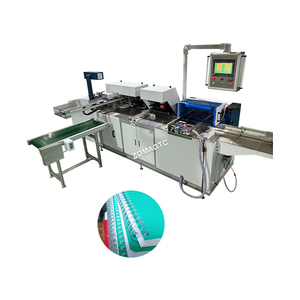

Spiral Notebook Maker Machine

Top sponsor listing

Top sponsor listing

About spiral notebook maker machine

Where to Find Spiral Notebook Maker Machine Suppliers?

China remains the global epicenter for spiral notebook maker machine manufacturing, with key production clusters in Henan and Zhejiang provinces driving innovation and cost efficiency. Henan, particularly Zhengzhou, hosts a dense network of paper processing and post-press machinery manufacturers, supported by integrated supply chains for steel components, electrical systems, and precision tooling. This regional concentration enables suppliers to achieve 20–35% lower production costs compared to counterparts outside Asia, primarily due to localized sourcing and streamlined logistics.

The industrial ecosystem in these regions supports both high-volume output and technical specialization. Manufacturers benefit from vertically integrated operations—spanning design, machining, assembly, and testing—within compact geographic zones. This infrastructure reduces lead times for standard models to 30–45 days, while enabling rapid prototyping for customized configurations. Buyers gain access to flexible production runs, ranging from single-unit desktop models to fully automated industrial lines capable of 1,500+ units per hour.

How to Choose Spiral Notebook Maker Machine Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Equipment Range

Verify that suppliers offer machines aligned with intended production scale: semi-automatic models (e.g., DWC-520 series) for small workshops, and fully automatic systems (e.g., WNB-420, NB-450) for industrial throughput. Confirm compliance with international safety standards such as CE, particularly for electrical and mechanical subsystems. Request documentation on motor specifications, punching accuracy (±0.1mm tolerance), and wire/coil compatibility (round, oval, square hole patterns).

Production Capability Verification

Assess supplier capacity through objective indicators:

- Facility size and dedicated R&D resources indicating long-term investment

- In-house engineering teams capable of customizing folding width, material thickness (up to 6mm), and binding speed

- Proven track record in delivering OEM/ODM solutions with branding, packaging, and interface language options

Cross-reference online revenue data and reorder rates as proxies for market acceptance and service reliability.

Transaction Safeguards & Quality Assurance

Prioritize suppliers with verifiable performance metrics: on-time delivery ≥98%, response time ≤3 hours, and reorder rates above 25%. Utilize secure payment mechanisms such as escrow services until final inspection is completed. Conduct pre-shipment audits or request factory videos to validate production processes. Sample testing should include stress trials on coil insertion, paper feed consistency, and die-cutting durability before scaling orders.

What Are the Best Spiral Notebook Maker Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhengzhou Zomagtc Co., Ltd. | Henan, CN | Paper Processing Machinery (1,449) | 100% | 41% | ≤2h | $1,300,000+ | Color, size, logo, packaging, graphic | $4,800 – $144,930 |

| Ningbo Bs Printing Machinery Equipment Co., Ltd. | Zhejiang, CN | Post-Press Equipment (211) | 100% | 26% | ≤2h | $50,000+ | Material, thickness, folding width, label | $4,600 – $5,100 |

| Henan Yingsheng Supply Chain Management Co., Ltd. | Henan, CN | Paper Processing Machinery (261) | 100% | <15% | ≤3h | $40,000+ | Size, material, hole pattern, packaging | $522 – $14,700 |

| ZOMAGTC CO., LTD | Unknown, CN | Paper Processing Machinery (435) | - | - | ≤2h | - | Folding width, thickness, logo, packing | $4,999 – $25,000 |

Performance Analysis

Zhengzhou Zomagtc Co., Ltd. stands out with the highest online revenue ($1.3M+) and a 41% reorder rate, indicating strong customer retention and scalable operations. The company offers a broad product range, including high-end fully automatic systems priced over $140,000, suitable for large-scale binderies. Ningbo Bs specializes in mid-range industrial machines with tight price consistency and full delivery reliability. Henan Yingsheng provides entry-level options starting at $522, ideal for startups or educational institutions needing desktop-sized units, though its low reorder rate suggests room for service improvement. ZOMAGTC CO., LTD presents competitive mid-tier automation but lacks transparency in delivery and reorder metrics, warranting additional due diligence.

FAQs

What are common customization options for spiral notebook maker machines?

Suppliers typically support modifications in coil diameter (3–25mm), paper thickness (up to 6mm), folding width (adjustable dies), and punching patterns (round, oval, square). Additional customization includes control panel language, machine color, branding labels, and packaging configuration for export readiness.

What is the typical MOQ and lead time?

Minimum order quantity is generally 1 set, even for high-end models. Lead times range from 15–20 days for standard machines and 30–45 days for customized or fully automated systems. Expedited production may be available upon negotiation.

Do suppliers provide technical support and after-sales service?

Most established suppliers offer remote troubleshooting via video guidance and English manuals. Some provide on-site installation support or training, especially for orders exceeding five units. Warranty periods typically cover 12 months on core components like motors and gearboxes.

Can spiral notebook machines handle different binding types?

Yes, many models are multi-functional: double-loop wire, single-loop, plastic coil, and calendar binding. Machines like the WNB-420 and DWC-520 series support quick-change tooling or mold-free adjustment, minimizing downtime between product variants.

How to verify machine quality before purchase?

Request sample production videos or live demonstrations via video call. Ask for test reports on cycle durability (≥10,000 cycles), noise levels (≤75dB), and power consumption. Independent third-party inspections (e.g., SGS) can be arranged pre-shipment to validate performance claims.