Styrofoam Box Making Machine Producer

CN

CN

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

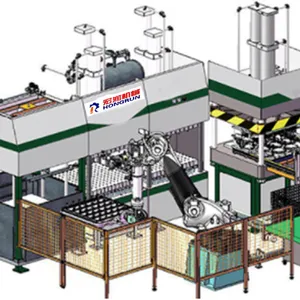

About styrofoam box making machine producer

Where to Find Styrofoam Box Making Machine Producers?

China remains the dominant hub for styrofoam (EPS) box making machine production, with key manufacturing clusters in Zhejiang and Shandong provinces. These regions host vertically integrated industrial ecosystems that support full-cycle development—from plastic extrusion and mold design to automated thermoforming assembly lines. Zhejiang, particularly Hangzhou and Ningbo, specializes in high-efficiency, fully automatic EPS molding systems, leveraging proximity to major ports for streamlined export logistics. Shandong’s Longkou-based manufacturers focus on cost-optimized solutions for food packaging and insulation applications, benefiting from localized access to polystyrene raw materials and auxiliary equipment suppliers.

The concentration of technical expertise and component vendors within 50km radii enables rapid prototyping and reduced lead times. Suppliers typically offer standard machine delivery within 30–45 days, with production costs 20–35% lower than equivalent European or North American manufacturers due to economies of scale and in-house engineering capabilities. Buyers gain flexibility in both volume procurement and customized configurations, supported by mature supply chains for hydraulic systems, steam boilers, CNC cutting units, and high-pressure pre-expanders.

How to Choose Styrofoam Box Making Machine Producers?

Effective supplier selection requires systematic evaluation across three core areas:

Technical and Process Compliance

Verify adherence to international quality standards such as ISO 9001 for quality management systems. For exports to regulated markets, CE marking is essential for electrical safety and mechanical compliance. Request documentation on critical subsystems—particularly heating/cooling cycles, pressure control units, and foam density consistency—to ensure operational reliability. Confirm compatibility with expandable polystyrene (EPS) grades and assess machine capability to maintain uniform foam density (typically 10–30 kg/m³) across batch runs.

Production Infrastructure Assessment

Evaluate supplier capacity through measurable indicators:

- Minimum factory area of 3,000m² indicating scalable operations

- In-house R&D teams capable of custom mold design and automation integration

- Vertical integration of key components: pre-expansion systems, steam distribution manifolds, and vacuum cooling circuits

Cross-reference facility size with on-time delivery performance (target ≥98%) and reorder rates (>15% indicates customer retention).

Transaction and Quality Assurance Protocols

Utilize secure payment mechanisms such as third-party escrow until post-delivery inspection is completed. Prioritize suppliers offering sample testing—evaluate machine output for dimensional accuracy, wall thickness consistency, and cycle time efficiency (typically 30–60 seconds per mold cycle). Demand trial production videos or remote facility audits to verify automation levels and quality control checkpoints before finalizing orders.

What Are the Leading Styrofoam Box Making Machine Producers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Fangyuan Plastics Machinery Co., Ltd. | Zhejiang, CN | 18+ | 50+ | 10,000+m² | 100.0% | ≤2h | 4.8/5.0 | <15% |

| Zhejiang Guiju Plastic Machinery Co., Ltd. | Zhejiang, CN | 12+ | 80+ | 8,500+m² | 100.0% | ≤2h | 4.7/5.0 | 20% |

| Longkou Fushi Packing Machinery Co., Ltd. | Shandong, CN | 15+ | 60+ | 7,000+m² | 100.0% | ≤7h | 4.6/5.0 | - |

| Longkou Deyi Machinery Group Co Ltd | Shandong, CN | 10+ | 100+ | 9,000+m² | - | ≤7h | 4.5/5.0 | - |

Performance Analysis

Zhejiang-based producers like Hangzhou Fangyuan and Zhejiang Guiju lead in automation and responsiveness, with sub-2-hour average reply times and proven export experience (US $120,000+ annual online revenue). Guiju stands out with a 20% reorder rate, reflecting strong client satisfaction in customization depth—including CNC mold engraving, water/air cooling options, and variable cycle time programming. Shandong manufacturers offer competitive pricing (as low as $20,000/set) but exhibit slower communication response patterns. All top-tier suppliers provide full line solutions encompassing pre-expansion, molding, and stacking systems, with customization available for box dimensions, logo imprinting, and material throughput capacity.

FAQs

How to verify styrofoam box making machine producer reliability?

Cross-check ISO and CE certifications with issuing bodies. Request factory audit reports or video walkthroughs to confirm in-house production capabilities. Analyze transaction history for consistent on-time delivery and evaluate customer feedback on after-sales service, particularly technical support for machine commissioning.

What is the typical sampling and lead time?

Sample machine configuration and testing take 20–35 days depending on customization level. Standard lead time for full production units ranges from 30 to 45 days post-deposit. Shipping via sea freight adds 15–30 days for international destinations.

Can suppliers handle global shipping and installation?

Yes, established manufacturers coordinate FOB and CIF shipments globally. Many offer optional overseas installation support and technician training. Confirm availability of local language manuals and PLC interface options (e.g., English, Spanish, Arabic) during procurement.

Do producers offer customization for mold design and output capacity?

All listed suppliers provide mold customization for box size, shape, and branding. Output capacity can be scaled from semi-automatic (1,000–2,000 boxes/hour) to fully automatic lines (up to 6,000 boxes/hour). Customization extends to foam density control, energy-efficient heating systems, and integrated stacking conveyors.

What are common MOQ and pricing structures?

Minimum Order Quantity is typically 1 set. Pricing varies by automation level: basic models start at $20,000, mid-range automatic systems range from $38,000–$60,000, while high-output, fully integrated lines exceed $95,000. Bulk orders may qualify for container-load discounts and reduced per-unit shipping costs.