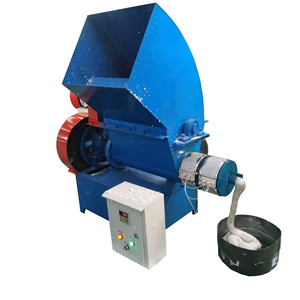

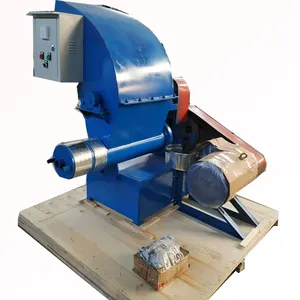

Styrofoam Densifier Machine

About styrofoam densifier machine

Where to Find Styrofoam Densifier Machine Suppliers?

China leads global production of styrofoam densifier machines, with key manufacturing clusters concentrated in Jiangsu and Henan provinces. These regions host vertically integrated facilities specializing in plastic recycling equipment, supported by mature supply chains for steel fabrication, electric components, and extrusion systems. Zhangjiagang in Jiangsu has emerged as a hub for industrial-scale foam processing machinery, where manufacturers leverage localized access to raw materials and port logistics to reduce lead times and export costs.

Suppliers in these zones typically operate consolidated production lines encompassing shredding, melting, compression, and granulation technologies. The proximity of component vendors, engineering teams, and testing labs within 50km enables rapid prototyping and assembly. Buyers benefit from scalable output—ranging from compact single-unit systems to turnkey recycling plants—with average delivery windows of 20–45 days for standard configurations. Cost efficiencies are significant, with Chinese suppliers offering 25–40% lower pricing compared to European or North American equivalents due to optimized labor and material sourcing.

How to Choose Styrofoam Densifier Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international safety and environmental standards. While not universally declared, CE marking indicates compliance with EU machinery directives, essential for customs clearance in regulated markets. ISO 9001 certification reflects structured quality management processes. Request documentation on motor efficiency, thermal control systems, and emission controls—particularly for hot-melt densifiers operating at high temperatures.

Production Capability Assessment

Evaluate supplier infrastructure through verifiable metrics:

- Facility size exceeding 3,000m² for consistent batch production

- In-house engineering teams capable of customizing feed hopper dimensions, screw design, and output capacity

- Integrated testing protocols for continuous operation under load (minimum 8-hour stress tests)

- Cross-reference on-time delivery rates (>97%) and response times (≤6 hours) as indicators of operational reliability

Transaction Security & Quality Verification

Utilize secure payment mechanisms such as escrow services to mitigate risk. Prioritize suppliers with transparent transaction histories and verified revenue data. Conduct pre-shipment inspections or request video audits of factory operations. Sample testing is critical—assess density ratio (input volume vs. output ingot size), energy consumption per kg processed, and material compatibility with EPS, EPE, and EVA foams.

What Are the Best Styrofoam Densifier Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Zhangjiagang Greenlandplast Machinery Co., Ltd. | Jiangsu, CN | Foam Machinery, Plastic Recycling Machines | US $30,000+ | 100.0% | ≤6h | - | $14,000–15,000 | 1 set |

| Zhangjiagang Qinfeng Machinery Co., Ltd. | Jiangsu, CN | Foam Machinery, Plastic Crushing Machines | - | 100.0% | ≤5h | - | $10,000–13,400 | 1 set |

| Henan Minko Machinery Co., Ltd. | Henan, CN | Other Machinery & Industrial Equipment | US $110,000+ | 100.0% | ≤3h | 17% | $2,000–2,999 | 1 set |

| Zhecheng Hong Xin Machinery Factory | Henan, CN | Customization Options Available | US $620,000+ | 100.0% | ≤2h | <15% | $1,200–1,900 | 1 set |

| Shanghai Lihu Information Technology Co., Ltd. | Shanghai, CN | Food Processing & Woodworking Machinery | US $30,000+ | 100.0% | ≤2h | <15% | $700–1,190 | 1 piece |

Performance Analysis

Jiangsu-based manufacturers like Greenlandplast and Qinfeng specialize in high-capacity, industrial-grade styrofoam densifiers, targeting commercial recycling operations with prices above $10,000. Their focus on foam-specific machinery correlates with robust build quality and higher throughput. In contrast, Henan and Shanghai suppliers offer entry-level models priced between $700–$3,000, suitable for small businesses or pilot projects. Zhecheng Hong Xin stands out with extensive customization capabilities—including color, logo, and packaging options—and the highest reported online revenue, indicating strong market penetration. All listed suppliers maintain 100% on-time delivery records, but response speed varies: Shanghai and Henan-based firms respond fastest (≤2h), enhancing communication efficiency during procurement cycles.

FAQs

What certifications should styrofoam densifier machine suppliers have?

Look for CE certification for compliance with European safety standards, especially for electrical and mechanical systems. ISO 9001 indicates formalized quality control procedures. While not always provided upfront, these credentials can be requested directly from suppliers prior to order placement.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 set, accommodating trial purchases. Lead times generally range from 15 to 30 days for standard units, extending to 45 days for customized systems. Express production may be available upon negotiation.

Can suppliers customize the machine for specific feedstock or output requirements?

Yes, several suppliers—particularly Zhecheng Hong Xin and Greenlandplast—offer customization in screw design, heating zone configuration, and output mold dimensions. Technical specifications such as input foam type (EPS, EPE, XPS), desired ingot size, and hourly throughput should be communicated early in discussions.

Do suppliers provide installation support or technical training?

While not explicitly stated in available data, many established manufacturers offer remote guidance via video or manuals. For complex installations, inquire about on-site technician dispatch options, potentially included in premium packages or negotiated separately.

How are machines packaged and shipped internationally?

Machines are typically crated in wooden cases for sea freight or palletized for air shipment. Confirm FOB terms and coordinate with freight forwarders for destination handling. Full container loads (FCL) are cost-effective for multiple units, while less-than-container (LCL) options suit smaller orders.