Supermax Cnc Machine

About supermax cnc machine

Where to Find Supermax CNC Machine Suppliers?

China remains the central hub for CNC machine manufacturing, with key supplier clusters concentrated in Shandong and Guangdong provinces. These regions host vertically integrated industrial ecosystems that support end-to-end production of precision machining equipment. Shandong, particularly cities like Jinan and Qingdao, is home to a high density of CNC machinery manufacturers specializing in vertical machining centers (VMCs), milling systems, and automated tooling solutions. The region benefits from proximity to steel suppliers and advanced component manufacturers, reducing material lead times by 15–20% compared to non-specialized zones.

Suppliers listed under the "supermax cnc machine" category operate within mature export-oriented networks, offering scalable production capacities and diversified product lines ranging from entry-level routers to high-precision 5-axis milling centers. Average factory sizes exceed 5,000m², enabling batch production and customization fulfillment. Most suppliers report on-time delivery rates above 97%, with response times typically under five hours—critical metrics for global buyers managing tight procurement schedules. Lead times for standard models range from 30 to 45 days post-deposit, while customized units may require up to 60 days depending on technical complexity.

How to Choose Supermax CNC Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

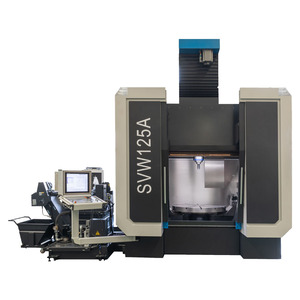

Confirm alignment between supplier offerings and required specifications: spindle power (ranging from 7.5kW to 22kW in documented listings), axis configuration (3-axis standard, 4–5 axis available), control systems (GSK, Fanuc, Siemens options noted), and worktable size. Prioritize suppliers listing multiple CNC variants (machining centers, lathes, routers) as evidence of diversified engineering expertise.

Production Infrastructure Assessment

Evaluate based on verifiable indicators:

- Facility scale supporting minimum 10+ unit monthly output

- In-house assembly lines with CNC machining and servo integration capabilities

- Dedicated quality testing protocols for runout accuracy, positioning repeatability, and thermal stability

Cross-reference online revenue data and reorder rates where available; suppliers reporting reorder rates above 100% indicate strong post-sale performance and customer retention.

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services until equipment passes destination inspection. Review supplier responsiveness (target ≤3 hours) and historical compliance with order timelines. For used or refurbished machines, request detailed maintenance logs, component replacement records, and operational hour meter readings to assess remaining service life.

What Are the Best Supermax CNC Machine Suppliers?

| Company Name | Main Products | Listings (CNC) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Value |

|---|---|---|---|---|---|---|---|

| Elite Frontier Enterprises Inc. | Machining Centre, CNC Lathe, Industrial Compressors | 976 | Not Specified | ≤5h | Not Specified | Not Specified | $16,700 |

| Jinan Jinshengxing Machinery Manufacture Co., Ltd. | CNC Router, Woodworking Machines, Motor Systems | Multiple Configurations | 100% | ≤2h | <15% | US $270,000+ | $3,000 |

| Longnan City Brotherholding Protective Equipment Co., Ltd. | Used Machining Centres, Metal Working Machines | 174 | 100% | ≤4h | 100% | US $5,000+ | $10,000 |

| Jinan Remax Machinery Technology Co., Ltd. | CNC Milling, Mini 5-Axis, Foam Cutting | Multiple Listings | 100% | ≤2h | <15% | US $10,000+ | $3,700 |

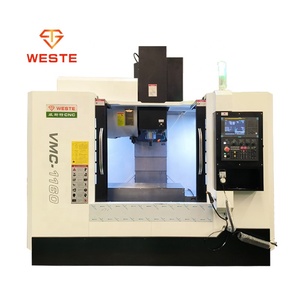

| Shandong Weste Cnc Machine Tool Co., Ltd. | Machining Centre, CNC Milling, Manual Mills | 570 | 100% | ≤3h | 100% | US $30,000+ | $8,000 |

Performance Analysis

Shandong Weste and Longnan Brotherholding demonstrate exceptional reliability with 100% on-time delivery and reorder rates, indicating robust after-sales support and machine durability. Jinshengxing and Remax stand out for rapid communication (≤2h response) and competitive pricing starting below $3,700, making them suitable for budget-conscious buyers seeking new CNC routers. Elite Frontier offers higher-end VMC models priced from $16,700 to $50,000, targeting industrial applications requiring rigidity and long-term uptime. Longnan specializes in pre-owned equipment, providing cost-effective access to Taiwan-origin YCM and Taikan models at approximately 40–60% of original purchase value.

FAQs

How to verify supermax CNC machine supplier reliability?

Validate through third-party trade assurance programs, review documented certifications (ISO 9001, CE if applicable), and request proof of past shipments via bill of lading samples. Conduct video audits of assembly lines and quality testing stations to confirm process rigor.

What is the typical MOQ and pricing range?

Most suppliers list a minimum order quantity of 1 unit. New CNC machines range from $3,000 for basic 1325 routers to $66,000 for high-specification 5-axis VMCs. Used industrial-grade units start at $10,000 with potential savings of 30–50% over new equivalents.

Can suppliers customize CNC machines?

Yes, customization is widely supported. Common configurable parameters include spindle type (air-cooled vs. water-cooled), tool changer configuration (ATC availability), control system (GSK, Syntec, Fanuc), working table (T-slot, vacuum), and rail length. Suppliers like Jinshengxing explicitly list over 20 modifiable features per unit.

Do suppliers offer warranties and technical support?

Standard warranties range from 12 to 24 months covering structural components and electrical systems. Reputable suppliers provide remote troubleshooting via TeamViewer or similar platforms, along with installation guides and training videos. On-site technician deployment may incur additional fees.

How are CNC machines packaged and shipped internationally?

Machines are containerized using seaworthy packaging with anti-vibration mounts and moisture barriers. FOB terms are common; buyers manage final freight and import clearance. Full-container loads (FCL) are recommended for multi-unit orders to reduce per-unit logistics costs. Air freight is viable only for compact desktop models due to weight constraints.