Supplier Capability Matrix

Top sponsor listing

Top sponsor listing

1/3

1/3

CN

CN

1/37

1/37

1/17

1/17

1/11

1/11

1/34

1/34

1/17

1/17

1/13

1/13

1/25

1/25

1/6

1/6

1/22

1/22

1/3

1/3

1/24

1/24

1/3

1/3

1/34

1/34

1/29

1/29

1/3

1/3

About supplier capability matrix

Where to Find Supplier Capability Matrix Providers?

China remains a central hub for industrial customization services, with key supplier clusters concentrated in Guangdong and Dongguan. These regions host vertically integrated manufacturing ecosystems specializing in precision engineering, metal fabrication, and design-driven solutions. Guangzhou and Shenzhen serve as innovation centers for advanced machining and custom product development, offering rapid prototyping, die casting, CNC processing, and full-shop interior design services across multiple industries including automotive, retail, beauty, and hospitality.

The proximity of raw material suppliers, technical workshops, and logistics networks enables streamlined production cycles. Suppliers in these zones typically operate within compact industrial parks where component sourcing, quality control, and shipping coordination occur within 50km radii. This integration supports lead times averaging 20–35 days for customized orders, 15–25% lower unit costs due to localized supply chains, and high flexibility for low-to-mid volume production runs. Buyers benefit from access to comprehensive service portfolios—from concept rendering to finished goods—under one regional ecosystem.

How to Evaluate Supplier Capability Matrix Strengths?

Assessing supplier capability requires structured analysis across technical, operational, and transactional dimensions:

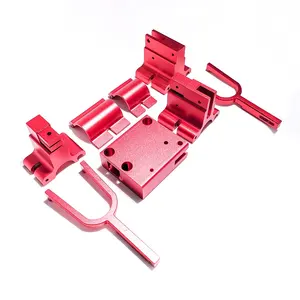

Production & Customization Capacity

Examine the breadth of manufacturing techniques offered: CNC machining, sheet metal fabrication, die casting, stamping, polishing, and 3D printing are indicators of technical versatility. Suppliers with over 100 active product listings in machining or casting demonstrate established production workflows. Look for explicit customization parameters such as material grade options (e.g., stainless steel, solid wood, tempered glass), dimensional tolerances, color finishes, logo integration, packaging configurations, and technical drawing support (2D/3D renderings, architectural plans).

Quality & Operational Performance

Prioritize suppliers with documented on-time delivery rates exceeding 95% and reorder rates above 20%, which reflect reliability and customer satisfaction. Response time under 2 hours indicates strong communication infrastructure. While formal certifications (ISO 9001, CE) are not explicitly listed in available data, consistent performance metrics serve as proxy indicators of internal quality management systems. Verify whether suppliers provide technical drawings, assembly instructions, and packaging labels as part of standard deliverables.

Transaction Transparency

Analyze pricing structures and minimum order quantities (MOQs). Competitive MOQs range from 1 set (for full-shop designs) to 500 pieces (for machined components), enabling scalable procurement strategies. Unit prices vary significantly by complexity—from $0.06 for simple stamped parts to $888+ for complete interior design sets. Confirm whether sample production is supported and if costs can be offset against future bulk orders. Ensure clarity on revenue scale (e.g., annual online revenue exceeding US $200,000) as an indicator of market presence and order-handling capacity.

What Are the Leading Supplier Capability Matrix Profiles?

| Company Name | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Key Processing Methods |

|---|---|---|---|---|---|---|---|

| ShenZhen Selection Hardware Technology Co.,Ltd. | Machining Services (243) Casting Services (127) Sheet Metal Fabrication (53) |

Polished finish, color, size, drawings, die casting, logo, mold, packaging, label | 100% | 40% | ≤2h | US $1,900,000+ | CNC Machining, Die Casting, Sheet Metal |

| Dongguan Pinbang Precision Spring Co., Ltd. | Springs (287) Machining Services (2) |

Limited customization; focuses on OEM CNC spring components | 93% | <15% | ≤2h | US $40,000+ | Spring Forming, CNC Machining |

| Guangzhou Guanzhu Showcase Co., Ltd. | Interior Design, Shop Displays, Furniture | Color, layout, material (solid wood, tempered glass), 3D renderings, floor plans, technical drawings, packaging | 90% | 18% | ≤2h | US $970,000+ | Woodworking, Glass Assembly, Structural Design |

| Guangzhou Heyi Decoration Engineering Co., Ltd. | Retail Furniture, Salon & Barber Shop Interiors | Material, size, color, logo, technical drawing, display layout, full-shop design | 100% | - | ≤1h | - | Furniture Fabrication, Interior Layout, Display Integration |

| Core Hardware Electronics Co., Ltd. | OEM/ODM Die Casting, CNC Parts, Stamping | Material, size, color, drawings, logo, packaging, graphic labeling | 90% | 22% | ≤2h | US $200,000+ | Diesel Casting, CNC Milling, Sheet Stamping, 3D Printing |

Performance Analysis

ShenZhen Selection Hardware stands out with the highest online revenue (US $1.9M+) and a 40% reorder rate, supported by extensive machining and casting capabilities. Its 100% on-time delivery and broad customization scope make it suitable for complex, high-volume industrial contracts. Dongguan Pinbang specializes in precision springs but shows limited diversification and low customer retention (<15% reorder rate), indicating niche applicability. Guangzhou Guanzhu offers comprehensive retail and salon design services with detailed 3D and structural documentation, though its 90% delivery rate suggests moderate risk exposure. Guangzhou Heyi excels in responsiveness (≤1h) and achieves perfect on-time performance, ideal for urgent design-to-fabrication projects despite missing financial data. Core Hardware Electronics balances mid-tier revenue with strong customization and a 22% repeat order rate, reflecting reliable execution in metal component manufacturing.

FAQs

How to assess a supplier’s customization capability?

Review listed customization parameters such as material types, dimensional ranges, surface finishes, branding options, and design deliverables (e.g., technical drawings, 3D models). Cross-reference product listings with actual service descriptions to confirm end-to-end process ownership—from prototyping to packaging.

What is the typical MOQ for customized hardware components?

Minimum order quantities range from 100 to 1,000 pieces depending on complexity. Simple stamped or machined parts often require 500–1,000 units, while specialized castings or fully assembled units may start at 100 pieces. Full interior design packages are quoted per set, typically with MOQs of 1–5 sets.

Are samples available before mass production?

Most suppliers support sample production. Lead times average 15–25 days for mechanical components and 10–20 days for design-based projects. Sample costs may apply but are frequently credited toward subsequent orders exceeding agreed volumes.

Do these suppliers handle international shipping?

Yes, all listed suppliers operate export-ready business models with documented global transaction histories. Confirm Incoterm preferences (FOB, CIF) and ensure compliance with destination-market standards for materials and electrical safety where applicable.

How to verify production capacity without onsite audits?

Request facility videos, machine lists, and workforce distribution data. Correlate claimed capabilities with product listing volume, revenue estimates, and delivery performance. High-volume suppliers should demonstrate dedicated R&D or design teams and maintain response times under 2 hours.