Supplier Efficiency Management System

CN

CN

CN

CN

About supplier efficiency management system

Where to Find Supplier Efficiency Management System Suppliers?

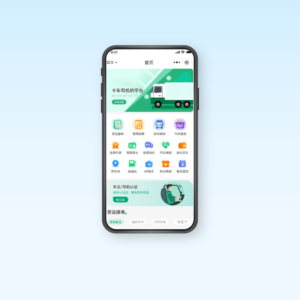

The global supplier base for supplier efficiency management systems is concentrated in China, with key clusters in Guangdong, Henan, and Shanghai. These regions host specialized technology firms integrating software development, IoT hardware, and cloud infrastructure into scalable enterprise solutions. Guangdong’s Pearl River Delta offers access to mature electronics manufacturing ecosystems, enabling rapid prototyping and integration of barcode scanners, RFID modules, and POS terminals. Shanghai combines strong software engineering talent with proximity to multinational enterprises, facilitating B2B customization for supply chain optimization.

Henan has emerged as a hub for industrial energy and asset monitoring systems, leveraging cost-efficient production and embedded system expertise. Suppliers in this region often integrate power metering, telemetry, and real-time data logging into unified platforms, catering to smart building and factory automation applications. The regional advantage lies in vertically aligned component sourcing—particularly for sensors, current transformers (CTs), and RS485 communication modules—reducing bill-of-materials costs by 15–25% compared to Western integrators.

How to Choose Supplier Efficiency Management System Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

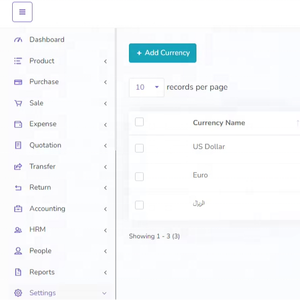

Software & System Architecture

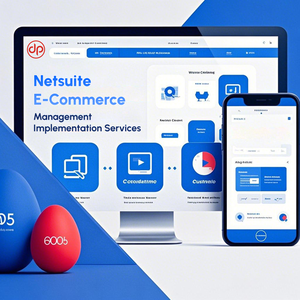

Prioritize suppliers offering modular, API-accessible platforms that support integration with existing ERP or inventory systems. Verify backend capabilities including cloud hosting (AWS/Azure compatibility), data encryption standards, and multi-tenant support. For manufacturing environments, confirm offline functionality and synchronization protocols under unstable network conditions.

Customization and Scalability

Assess the extent of available customization:

- Branding options (logo, UI color schemes, packaging)

- Functional tailoring (barcode vs. RFID tracking, single-phase vs. three-phase energy monitoring)

- Protocol adaptability (Modbus, Wi-Fi, DIN rail compatibility, prepaid relay control)

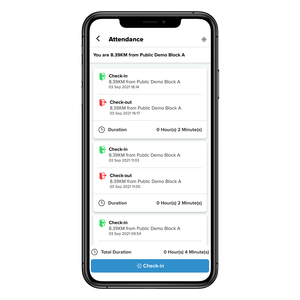

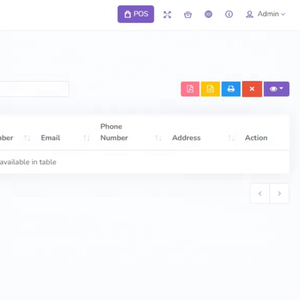

- Support for industry-specific workflows (warehouse issue tracking, manpower planning, omnichannel POS)

Validate scalability through documented case studies or sandbox testing, particularly for deployments exceeding 50 concurrent users or 1,000+ tracked assets.

Transaction and Delivery Performance

Analyze verifiable performance metrics:

- On-time delivery rate ≥98%

- Average response time ≤5 hours

- Reorder rate as an indicator of customer retention

- Minimum order quantity (MOQ) alignment with pilot project needs

Suppliers with transparent online revenue disclosure and third-party transaction verification offer higher trust levels. Request demonstration accounts or trial licenses before procurement.

What Are the Best Supplier Efficiency Management System Suppliers?

| Company Name | Location | Main Products | Price Range (Min Order) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Fengyijie Electronic Technology Co., Ltd. | Guangdong, CN | Asset Management Systems, Omnichannel POS | $99–199; $699–999 | 1 set | 93% | ≤5h | 17% | Color, size, logo, packaging, label |

| Henan Compere Smart Technology Co., Ltd. | Henan, CN | Energy Management, Meter Reading Systems | $30–55; $50 | 5–100 sets | 98% | ≤3h | <15% | CT size, protocol, WiFi, relay, graphic, material, packaging |

| Shanghai Jigong Intelligent Information Technology Co., Ltd. | Shanghai, CN | Supplier Relationship Management Software | $1,000 | 1 piece | 100% | ≤9h | - | Full SRM customization, manufacturing-class features |

| SERVEDECK INNOVATION SDN. BHD. | Malaysia | Cloud-Based Inventory, Smart Asset Management | $10–20 | 5 units | - | ≤2h | - | Limited (software-focused, 90 listings) |

| HANGZHOU ALLROOT Software Co., Ltd. | Zhejiang, CN | ERP Integration, Manufacturing Optimization | $100 | 1 piece | 100% | ≤5h | - | Logo, color, functional customization |

Performance Analysis

Henan Compere leads in responsiveness (≤3h) and on-time delivery (98%), making it ideal for time-sensitive deployments requiring industrial telemetry integration. Guangzhou Fengyijie offers competitive pricing and low MOQs, suitable for small businesses adopting asset tracking or retail POS upgrades. Shanghai Jigong specializes in high-end supplier relationship management (SRM) software with full customization, targeting mid-to-large enterprises optimizing vendor performance analytics. SERVEDECK stands out for ultra-low-cost cloud-based inventory tools but lacks reorder rate transparency. HANGZHOU ALLROOT provides robust ERP-linked systems at accessible price points, with proven delivery reliability.

FAQs

How to verify supplier efficiency management system reliability?

Cross-check claimed delivery rates and response times via platform-verified transaction histories. Request references or demo access to evaluate system stability, user interface clarity, and reporting accuracy. For hardware-integrated systems, verify compliance with CE, RoHS, or IEC standards where applicable.

What is the typical lead time for customized systems?

Standard software configurations deploy within 5–10 days post-payment. Fully customized SRM or ERP-integrated systems require 3–6 weeks for development, testing, and client review. Hardware-dependent solutions (e.g., smart meters with CT installation) may extend to 8 weeks depending on component availability.

Do suppliers support global deployment?

Yes, most suppliers offer multilingual interfaces and cloud hosting compatible with international networks. Confirm data residency policies, GDPR compliance (if applicable), and local technical support availability. Some providers offer remote configuration and training via video conferencing.

Are samples or trial versions available?

Software suppliers typically provide free trial accounts (7–30 days). For hardware-inclusive systems, expect sampling fees covering 30–50% of unit cost, refundable upon bulk order placement. MOQs range from 1 set (software) to 100 units (mass-deployment metering kits).

How to negotiate better terms with suppliers?

Leverage long-term support agreements or volume commitments (≥100 units) to secure discounts, extended warranties, or free customization. Prioritize suppliers with high on-time delivery and response metrics to reduce project risk. Use milestone-based payment structures tied to delivery, installation, and acceptance phases.