Supply Chain And Operations

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

CN

CN

CN

CN

About supply chain and operations

Where to Find Supply Chain and Operations Solution Providers?

China has emerged as a central hub for integrated supply chain and operations service providers, with concentrated expertise in Zhejiang and Shanghai regions. Hangzhou and Shanghai host specialized clusters combining advanced manufacturing capabilities with digital transformation services, enabling end-to-end solutions from logistics automation to enterprise software integration. These hubs benefit from proximity to major ports and robust ICT infrastructure, facilitating seamless export operations and global service delivery.

The ecosystem supports both hardware and software-centric offerings, including automated sorting systems, transmission components, and ERP-driven supply chain platforms. Vertically integrated production networks allow rapid prototyping and scalable deployment, with average lead times ranging from 15–30 days for standard software implementations and 45–60 days for custom machinery. Buyers gain access to suppliers capable of delivering modular systems compliant with international performance benchmarks, supported by responsive technical teams and cloud-based monitoring frameworks.

How to Choose Supply Chain and Operations Suppliers?

Selecting qualified partners requires rigorous evaluation across three critical dimensions:

Technical Capability and Compliance

Prioritize suppliers offering documented adherence to recognized quality management standards. While formal certifications (e.g., ISO 9001) are not universally listed, verified manufacturers demonstrate compliance through consistent on-time delivery performance (>97%) and structured development processes. For software solutions, validate compatibility with existing ERP or POS systems and confirm support for data interoperability protocols.

Production and Service Infrastructure

Assess operational scale and specialization based on available metrics:

- Facility size and R&D capacity indicated by product diversity and customization depth

- In-house engineering teams capable of system design, integration, and post-deployment maintenance

- Demonstrated response time ≤2 hours, signaling dedicated client support structures

Cross-reference online revenue indicators and reorder rates where available to assess market validation and customer retention.

Transaction Security and Performance Verification

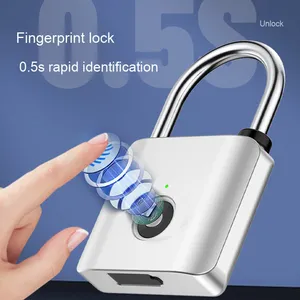

Utilize transaction safeguards such as milestone-based payments and independent inspection clauses. Evaluate supplier reliability through verifiable performance data—on-time delivery rates exceeding 98%, sub-2-hour response times, and repeat order activity. For high-value automation equipment, require factory acceptance testing (FAT) prior to shipment and confirm availability of remote diagnostics or on-site commissioning support.

What Are the Best Supply Chain and Operations Suppliers?

| Company Name | Location | Verified Supplier Type | Main Offerings | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Ocean Industry Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Transmission Chains, Sprockets, Gearboxes, Agricultural Parts | 97% | ≤2h | US $680,000+ | 25% | Pitch, material, length, branding, packaging, drawings |

| Jinshi Yifu (Hangzhou) Technology Co., Ltd. | Zhejiang, CN | Trusted Service Provider | Global Supply Chain Services, Data Center Operations | 100% | ≤2h | - | - | Color, material, size, logo, packaging, graphic |

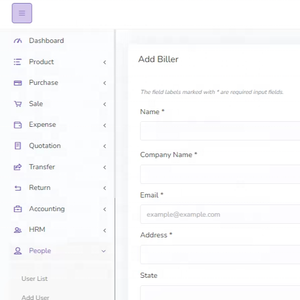

| KAEM SOFTWARES PRIVATE LIMITED | India | - | Supply Chain Management Software, ERP Systems | - | ≤2h | US $8,000+ | - | Limited (software configuration) |

| Shanghai Honghuan Network Technology Co., Ltd. | Shanghai, CN | Multispecialty Supplier | Procurement Management Systems, Supplier Relationship Platforms | 100% | ≤2h | - | - | System architecture, workflow logic, interface design |

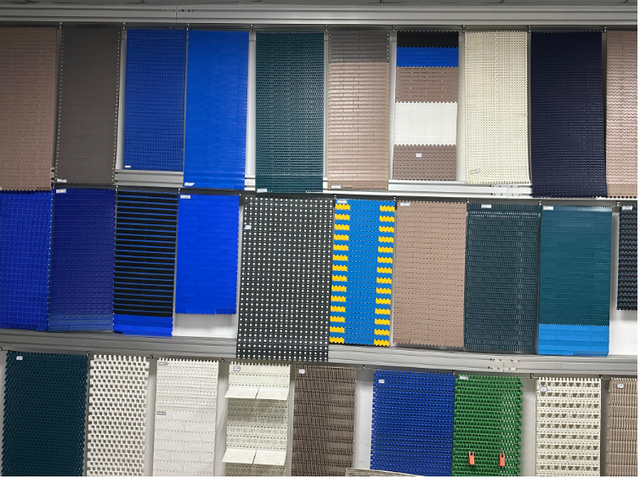

| Zhejiang Xinli Electrical Equipment Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Loop Cross-Belt Sorters, Parcel Sorting Systems | 100% | ≤1h | US $110,000+ | <15% | Color, material, size, logo, packaging, label, graphic |

Performance Analysis

Zhejiang-based manufacturers exhibit strong responsiveness and technical precision, with Zhejiang Xinli achieving 100% on-time delivery and sub-hour response times for high-capacity sorting systems. Jinshi Yifu and Shanghai Honghuan specialize in digital operations frameworks, offering scalable cloud-connected platforms tailored to e-commerce and data center logistics. Hangzhou Ocean Industry stands out in mechanical components, combining corrosion-resistant materials with extensive customization across chain dimensions and branding elements.

Software-focused providers like KAEM Software offer cost-effective entry points (from $95/set), suitable for SMEs seeking modular supply chain digitization. In contrast, automated material handling systems start at $49,000 per set, reflecting higher capital investment but long-term efficiency gains. Suppliers with proven reorder activity (e.g., 25% at Hangzhou Ocean) indicate sustained client satisfaction and after-sales support effectiveness.

FAQs

How to verify supply chain and operations supplier reliability?

Validate performance claims through documented delivery records and client references. Request evidence of system testing, code audits (for software), or mechanical stress reports (for hardware). Analyze response consistency and technical depth in communications as proxies for service maturity.

What is the typical minimum order quantity (MOQ)?

MOQ varies significantly by product type: software licenses often require only 2 units, while physical systems range from 1 set (automation equipment) to 1,000–10,000 units (integrated service packages). Component suppliers may enforce volume thresholds based on production batch efficiencies.

Are customization options widely available?

Yes, most suppliers offer configurable parameters including size, color, labeling, and branding. Advanced modifications—such as custom pitch in transmission chains or algorithmic adjustments in sorting software—require direct engineering consultation and may affect lead time.

Do suppliers support global deployment?

Established providers accommodate international clients with multilingual interfaces, cloud-hosted platforms, and modular hardware designed for cross-border logistics. Confirm compatibility with local power standards, network protocols, and regulatory requirements before procurement.

What are common payment and delivery terms?

Standard arrangements include milestone payments for development projects and FOB shipping for equipment. High-value orders often require deposit structures (30–50%) with balance settlement upon delivery verification. Some suppliers integrate secure transaction mechanisms to protect both parties during initial engagements.