Supply Chain Operations

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About supply chain operations

Where to Find Supply Chain Operations Solution Providers?

China leads in the development and delivery of integrated supply chain operations solutions, with key clusters in Zhejiang, Liaoning, and Shanghai offering specialized capabilities. Hangzhou and Shanghai serve as hubs for digital transformation technologies, hosting firms that develop ERP systems, logistics automation software, and AI-driven supply chain platforms. These regions benefit from proximity to tech talent pools and advanced data infrastructure, enabling rapid deployment of scalable enterprise solutions.

The industrial ecosystem supports both hardware and software integration, allowing suppliers to offer turnkey systems—from smart conveyor chains to cloud-based management platforms. This convergence enables end-to-end visibility across procurement, production, warehousing, and distribution. Buyers gain access to vertically aligned service providers capable of delivering modular or fully customized solutions with lead times averaging 15–30 days for software deployment and 30–45 days for automated equipment fulfillment.

How to Choose Supply Chain Operations Suppliers?

Selecting reliable partners requires a structured evaluation across technical capability, transaction performance, and customization capacity:

Technical Expertise & Product Range

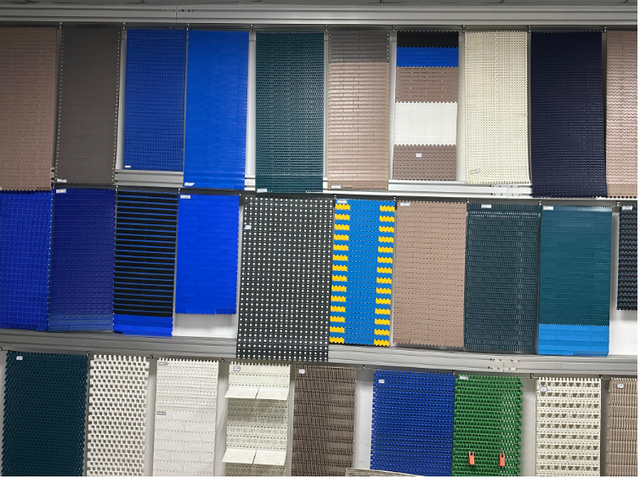

Assess core competencies through product segmentation. Leading suppliers typically specialize in either software systems (ERP, SRM, WMS) or physical automation equipment (chain conveyors, logistics transporters). Confirm domain experience—software providers should demonstrate proven implementations in supply chain digitization, while hardware manufacturers must show engineering proficiency in material handling systems.

Performance Metrics Verification

Prioritize suppliers with verifiable operational track records:

- On-time delivery rate ≥97%

- Average response time ≤3 hours

- Reorder rate above 25% indicating client retention

Cross-reference these metrics with project scale and complexity. High reorder rates often correlate with post-sale support quality and system adaptability.

Customization & Integration Capability

Evaluate flexibility in design and implementation:

- Software vendors should support API integrations, UI branding, workflow customization, and multi-tenant deployments

- Equipment suppliers must offer configurability in dimensions, materials, load capacity, drive mechanisms, and control interfaces

- Demand technical drawings, 3D models, or system demos prior to commitment

Transaction Safeguards

Implement risk mitigation protocols:

- Require documented testing procedures for software validation or mechanical stress tests

- Use secure payment terms with milestone-based releases

- Analyze online revenue indicators and order history to assess financial stability and market demand

What Are the Best Supply Chain Operations Suppliers?

| Company Name | Specialization | Main Products (Listings) | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

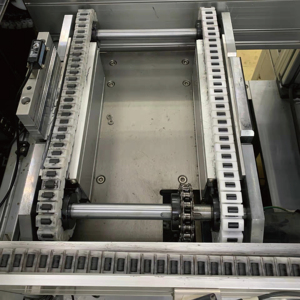

| Hangzhou Ocean Industry Co., Ltd. | Mechanical Components | Transmission Chains (1157), Rack Gears (212) | 97% | ≤2h | 26% | US $670,000+ | Size, material, pitch, branding, packaging, sprockets |

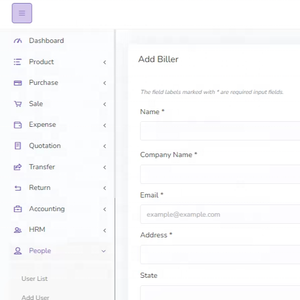

| Shanghai Jigong Intelligent Information Technology Co., Ltd. | Software Solutions | ERP, SCM, SRM Systems | 100% | ≤11h | - | - | System modules, UI, process flows |

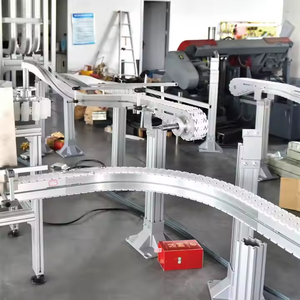

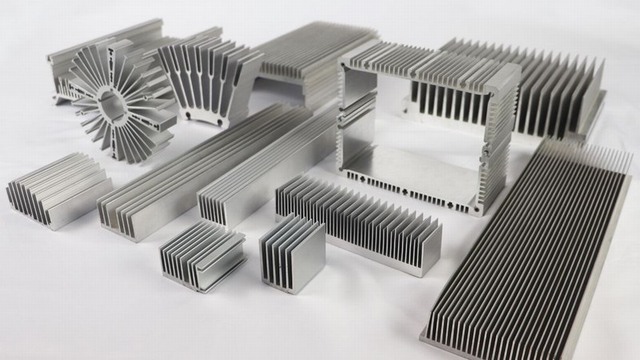

| Shenyang Toshine Aluminum Co., Ltd. | Automated Conveyors | Chain Conveyor Systems (5) | 100% | ≤3h | 62% | US $240,000+ | Color, logo, label, packaging |

| Jinshi Yifu (Hangzhou) Technology Co., Ltd. | Global IT Logistics | Data Center, O&M, Global Services | 100% | ≤3h | - | - | Material, size, graphic, packaging |

| KAEM SOFTWARES PRIVATE LIMITED | Digital SCM Software | Software (1267), POS Systems | - | ≤2h | - | US $8,000+ | Custom-designed workflows, retail models |

Performance Analysis

Shenyang Toshine stands out with a 62% reorder rate, reflecting strong customer satisfaction in automated conveyor systems, supported by fast response times and consistent on-time delivery. Hangzhou Ocean Industry demonstrates high scalability in mechanical components, backed by extensive product listings and robust online revenue. Software-focused suppliers like Shanghai Jigong and KAEM SOFTWARES offer affordable entry points ($95–$1,000 minimum orders), ideal for SMEs seeking digital transformation. However, limited reorder data suggests newer market presence or less mature client relationships. Jinshi Yifu differentiates through global service offerings tailored to IT and data center supply chains, targeting enterprise-level clients with large-volume requirements (1,000+ units).

FAQs

How to verify supply chain operations supplier reliability?

Validate performance claims through documented delivery records, client references, and third-party transaction histories. For software providers, request case studies or pilot access. For equipment suppliers, conduct virtual factory audits to confirm production lines and quality control processes.

What is the typical lead time for supply chain solutions?

Software implementations typically require 10–20 days for configuration and deployment. Customized automation systems take 30–45 days for manufacturing and testing. Standard conveyor sets may ship within 15 days if in stock.

Can suppliers integrate with existing enterprise systems?

Yes, leading software providers support integration with ERP, CRM, and inventory management platforms via APIs. Confirm compatibility with your current stack before procurement. Hardware systems often include PLCs or SCADA interfaces for seamless plant-floor connectivity.

Do suppliers offer free samples or trial versions?

Software vendors frequently provide demo versions or limited-feature trials. Physical equipment sampling varies—some suppliers waive fees for bulk commitments, while others charge partial production costs. Expect 30–50% cost recovery for conveyor system samples.

How to initiate customization requests?

Submit detailed specifications: for software, define required modules, user roles, reporting needs, and integration points; for hardware, specify dimensions, load capacity, speed, motor type, and environmental conditions. Reputable suppliers respond with technical proposals, CAD drawings, or system mockups within 72 hours.