Thread Making Machine Producer

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About thread making machine producer

Where to Find Thread Making Machine Producers?

China remains the global epicenter for thread making machine manufacturing, with key industrial hubs concentrated in Shandong, Guangdong, and Hebei provinces. These regions host vertically integrated supply chains that support rapid prototyping and high-volume production of textile and fastener machinery. Shandong is home to established producers like Qingdao Tongda and Taian Jiamei, leveraging proximity to port infrastructure and steel suppliers to reduce material costs by 15–20%. Guangdong’s Foshan cluster specializes in precision metalworking equipment, particularly automatic screw and thread rolling machines, while Hebei's Cangzhou-based manufacturers focus on compact winding systems for small-scale textile operations.

The regional ecosystems enable efficient coordination between component suppliers, R&D departments, and assembly lines—often within a 50-kilometer radius. This integration translates into shorter lead times (typically 30–45 days for standard configurations), scalable output, and cost advantages over Western or Southeast Asian alternatives. Buyers benefit from access to modular machine designs adaptable to cotton, polyester, nylon, PP, and specialty fibers such as polyglycolic acid surgical thread.

How to Choose Thread Making Machine Producers?

Selecting a reliable producer requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Expertise & Product Range

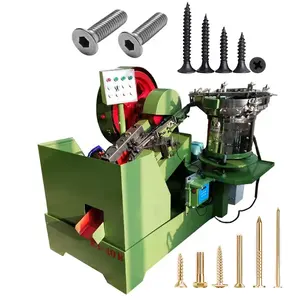

Assess whether the supplier specializes in textile spinning systems or metal thread forming equipment, as application requirements differ significantly. Textile-focused producers like Qingdao Tongda offer full-line spinning and weaving machines capable of handling daily outputs up to several tons, supporting customization in yarn count, bobbin size, and nonwoven packaging. In contrast, metal thread producers such as Foshan Heling and Xingtai Shengjian specialize in CNC-controlled thread rolling machines for bolts, screws, and trapezoidal threads, with precision tolerances under ±0.02mm.

Production Capacity Verification

Evaluate facility maturity through measurable indicators:

- Minimum factory area exceeding 3,000m² for sustained batch production

- In-house machining capabilities including CNC milling, hydraulic pressing, and automated control systems

- Dedicated R&D units focused on process optimization and energy efficiency improvements

Cross-reference product listing volume with on-time delivery performance—suppliers maintaining 100% fulfillment rates demonstrate operational reliability.

Quality Assurance & Compliance

Confirm adherence to international quality standards such as ISO 9001. While not all suppliers list formal certifications in public data, consistent on-time delivery (≥98%) and responsive communication (≤3 hours average response) serve as proxy indicators of robust internal QA protocols. For export compliance, verify machine compatibility with destination-market electrical standards (e.g., 380V/50Hz vs. 220V/60Hz) and safety regulations.

Transaction Security & After-Sales Support

Prioritize producers offering third-party payment protection mechanisms and documented dispute resolution procedures. Request pre-shipment inspection rights and clarify warranty terms covering core components (e.g., motors, spindles, drive systems). Sample testing is strongly advised—benchmark thread tensile strength, surface finish, and dimensional accuracy before scaling procurement.

What Are the Leading Thread Making Machine Producers?

| Company Name | Location | Main Products | Listing Volume | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Estimate | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Qingdao Tongda Textile Machinery Co., Ltd. | Shandong, CN | Spinning Machines, Weaving Machines | 504+ listings | 100.0% | ≤2h | 60% | US $430,000+ | Yarn type, capacity, system configuration, raw material input |

| Taian Jiamei Machinery Technology Co., Ltd. | Shandong, CN | Spinning Machines, Plastic Extruders | 1,908+ listings | 100.0% | ≤7h | <15% | US $8,000+ | Fiber length, feeding diameter, twist rate, spinning system |

| Foshan Heling Machinery Equipment Co., Ltd. | Guangdong, CN | Thread Rolling Machines | 188+ listings | 100.0% | ≤3h | - | - | Screw dimensions, motor power, double-headed configurations |

| Xingtai Shengjian Machinery Manufacturing Co., Ltd. | Hebei, CN | Thread Rolling Machines, CNC Mills | 68+ listings | 100.0% | ≤2h | - | - | Thread pitch, trapezoidal profiles, hollow pipe threading |

| Cangzhou Zhushi Textile Equipment Co., Ltd. | Hebei, CN | Winding Machines | 487+ listings | 100.0% | ≤4h | - | - | Spindle count, operation simplicity, batch processing |

Performance Analysis

Qingdao Tongda stands out with the highest reorder rate (60%) and substantial online revenue, indicating strong customer retention and market trust, likely driven by broad customization options and consistent service delivery. Taian Jiamei offers extensive product diversity but reports a low reorder rate, suggesting potential gaps in post-sale support or value perception despite large-scale listing presence. Foshan Heling and Xingtai Shengjian cater to niche industrial markets with specialized thread rolling solutions, featuring competitive pricing ($16,200–$28,674 per unit) and tight response cycles. Cangzhou Zhushi provides entry-level winding machines at accessible price points ($400–$2,000), ideal for startups or regional workshops requiring simple, low-maintenance systems.

FAQs

What materials can thread making machines process?

Textile machines handle natural and synthetic fibers including cotton, polyester, nylon, PP, PET, and biodegradable polymers like PGA. Metal thread machines are designed for carbon steel, stainless steel, aluminum, and alloy rods, supporting various hardness grades and diameters.

What is the typical minimum order quantity (MOQ)?

Most producers require an MOQ of 1 set for complete machines. Some offer single-piece sales for compact models like spindle winders, especially when targeting small businesses or replacement units.

Are customization options available?

Yes. Full customization includes adjustments to output capacity, raw material input specifications, automation level, voltage requirements, and branding elements. Lead time may extend by 10–20 days depending on complexity.

How long does production and shipping take?

Manufacturing lead time ranges from 20–45 days based on machine type and customization level. International shipping via sea freight typically adds 25–40 days to major global ports. Air freight reduces transit time to 5–10 days but increases logistics costs significantly.

Do suppliers provide installation and training?

Many offer remote guidance via video tutorials or manuals. On-site commissioning and operator training are often available at additional cost, particularly for complex spinning or extrusion lines.