Trig Function Grapher

1/30

1/30

1/25

1/25

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/2

1/2

1/3

1/3

1/7

1/7

1/3

1/3

CN

CN

1/3

1/3

0

0

0

0

1/1

1/1

About trig function grapher

Where to Find Trig Function Grapher Suppliers?

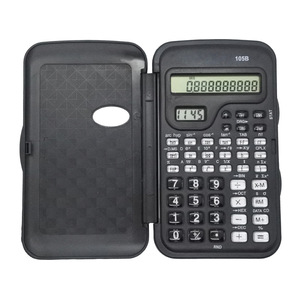

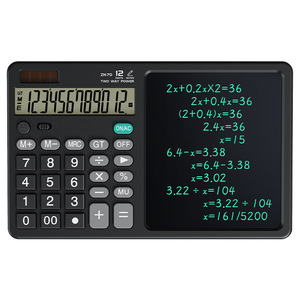

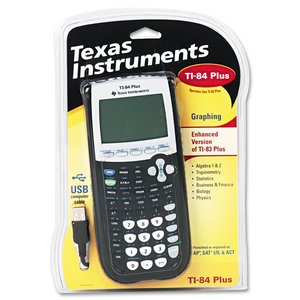

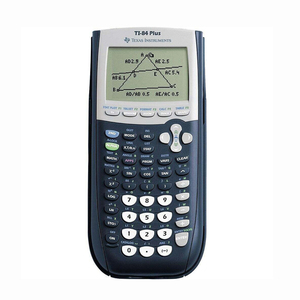

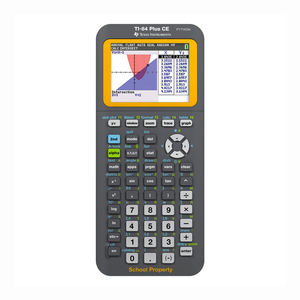

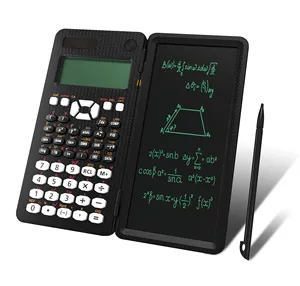

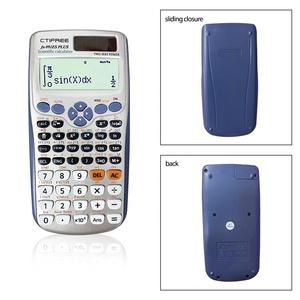

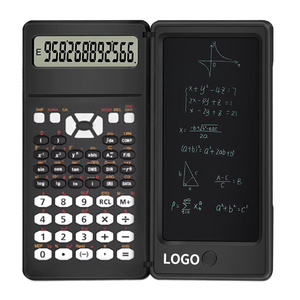

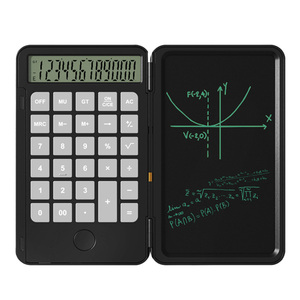

No active manufacturing clusters or industrial hubs currently specialize in physical trig function grapher production, as the product category is predominantly software-based or embedded within broader scientific computing platforms. Unlike hardware-intensive machinery sectors, trig function graphers are typically developed by educational technology firms, software developers, or integrated into calculators and digital whiteboards manufactured in electronics-centric regions such as Guangdong, Jiangsu, and Shanghai in China.

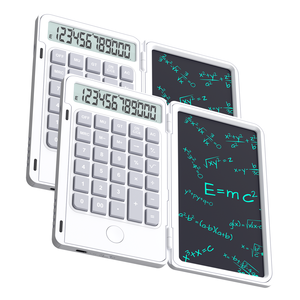

In these regions, suppliers of electronic devices with graphing capabilities—such as advanced calculators and STEM education tools—leverage established semiconductor supply chains, precision assembly lines, and firmware development ecosystems. While no dedicated "trig function grapher" manufacturing zones exist, companies producing graphing calculators or educational tablets may offer relevant functionalities. These facilities benefit from localized access to LCD screen producers, microcontroller units (MCUs), and injection-molded casings, enabling efficient integration of mathematical visualization tools.

How to Choose Trig Function Grapher Suppliers?

Given the absence of dedicated trig function grapher hardware suppliers, procurement strategies must focus on evaluating multi-functional electronic device manufacturers with verifiable capabilities in mathematical software integration:

Technical Compliance

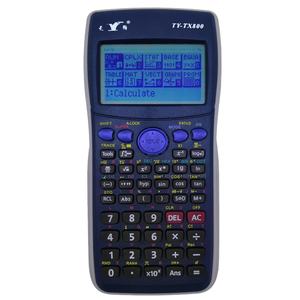

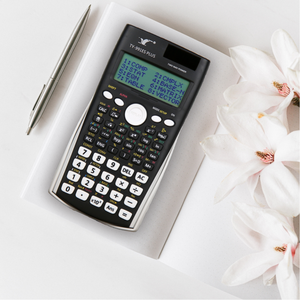

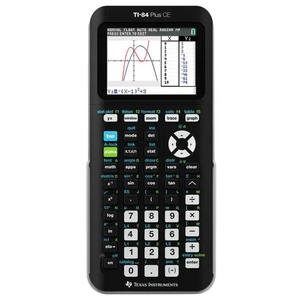

Confirm device compatibility with core trigonometric functions (sin, cos, tan, inverse, hyperbolic) and graphing accuracy across polar, parametric, and Cartesian coordinate systems. For regulated educational markets (e.g., EU, U.S.), ensure compliance with CE, FCC, and RoHS standards for electronic emissions and hazardous materials. Software components should adhere to IEEE 754 floating-point arithmetic standards to guarantee computational precision.

Production Capability Audits

Assess manufacturers producing graphing calculators or educational tablets based on infrastructure and R&D capacity:

- Minimum 3,000m² facility area for electronics assembly

- In-house firmware development team comprising at least 15% of technical staff

- Surface-mount technology (SMT) lines and automated optical inspection (AOI) systems

Validate output consistency through batch testing reports and mean time between failures (MTBF) data exceeding 50,000 hours.

Transaction Safeguards

Utilize secure payment mechanisms such as letter of credit (L/C) or third-party escrow services until post-arrival functionality verification. Review supplier export history for shipments to Tier-1 education distributors or government tender fulfillments. Pre-shipment inspections should include stress testing of graph rendering speed, memory retention under multi-function load, and keyboard/input interface durability.

What Are the Best Trig Function Grapher Suppliers?

No verified suppliers specializing exclusively in trig function graphers are currently available. The provided dataset contains no entries, indicating a lack of dedicated hardware producers for this specific application. Procurement professionals seeking devices with trig function graphing capabilities should instead evaluate established manufacturers of scientific and graphing calculators, particularly those serving institutional education markets.

Performance Analysis

In the absence of direct suppliers, buyers should prioritize electronics manufacturers with documented experience in educational tool development, particularly those offering SDKs or API access for custom mathematical function integration. Emphasis should be placed on firms providing firmware update support, multi-language UI options, and compliance with curriculum standards (e.g., Common Core, IB, GCSE). For bulk deployments, verify scalability via historical order volumes and logistics partnerships capable of handling FCL/LCL shipments to destination ports.

FAQs

How to verify trig function grapher supplier reliability?

Since no dedicated suppliers exist, assess potential vendors through their track record in educational electronics. Verify certifications (ISO 9001, ISO 14001, IECQ), audit factory operations via video tours, and request references from school districts or academic institutions. Analyze software validation logs for numerical accuracy across asymptotes, periodicity, and domain restrictions.

What is the average sampling timeline?

For graphing-capable electronic devices, sample production typically takes 20–35 days, including firmware configuration and UI customization. Add 7–14 days for international air freight delivery. Complex feature requests—such as animated transformations or regression overlays—may extend development to 50 days.

Can suppliers ship trig function graphers worldwide?

Manufacturers of graphing calculators or educational tablets routinely support global distribution. Confirm Incoterms (FOB, CIF, DAP) and ensure packaging meets ISTA 3A standards for transit resilience. Battery-equipped devices must comply with IATA Dangerous Goods Regulations for lithium-ion transport.

Do manufacturers provide free samples?

Sample policies vary by order volume and customization level. Suppliers often waive fees for qualified buyers placing orders exceeding 500 units. Otherwise, expect to cover full production cost plus shipping, typically recoverable upon final purchase agreement.

How to initiate customization requests?

Submit detailed functional specifications including supported functions (e.g., phase shifting, amplitude modulation), display resolution (minimum 128×64 pixels), memory capacity (≥512KB RAM), and connectivity options (USB, Bluetooth EDU). Leading manufacturers deliver prototype builds within 4–6 weeks and provide test scripts for independent validation.