Types Of Production System With Examples

1/18

1/18

1/26

1/26

About types of production system with examples

Where to Find Production System Suppliers?

China remains the global epicenter for industrial production system manufacturing, with specialized clusters in Guangdong, Sichuan, and Foshan delivering scalable solutions across sectors. Guangdong hosts advanced electronics and conveyor-based assembly lines, leveraging proximity to Shenzhen’s tech supply chains to support rapid prototyping and integration. Sichuan and Foshan have emerged as leaders in agricultural and food processing systems, where vertical farming and hydroponic production units benefit from localized R&D in sustainable agtech.

These regions offer vertically integrated ecosystems combining engineering design, component fabrication, and final assembly within compact geographic zones. This integration enables lead times averaging 30–45 days for standard configurations, with cost advantages of 20–35% over Western counterparts due to optimized labor, materials, and logistics networks. Buyers gain access to suppliers capable of fulfilling both high-volume orders and engineered-to-order systems, supported by mature export infrastructure and digital sourcing platforms.

How to Choose Production System Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical capability, quality assurance, and transactional reliability:

Technical & Engineering Validation

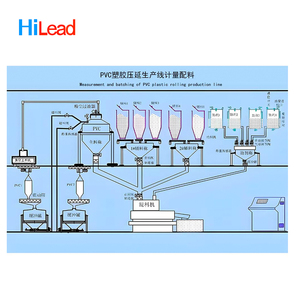

Confirm supplier expertise in relevant production methodologies—such as batch, continuous flow, or automated assembly systems—through product-specific documentation. For electronics or HVAC assembly lines, verify integration capabilities with programmable logic controllers (PLCs), motor drive systems, and material handling components. Demand schematics and layout designs prior to order confirmation.

Quality Management Systems

Prioritize suppliers adhering to recognized standards such as ISO 9001 for quality control processes. While not all suppliers list formal certifications, consistent on-time delivery rates above 85% and documented response protocols indicate operational maturity. For food-grade or medical-adjacent applications, ensure compliance with hygiene standards via material specifications (e.g., SUS-304 stainless steel, food-safe PVC belts).

Production Capacity & Customization Scope

Assess scalability through key indicators:

- Minimum facility size of 3,000m² for full-line production

- In-house customization options including belt width, drive configuration, bi-directional operation, and labeling systems

- Capacity to modify structural dimensions, load ratings, and power sources (AC/DC, single/multi-phase)

Cross-reference listed product ranges with customization tags to confirm engineering flexibility.

Transaction & Risk Mitigation

Utilize secure payment structures such as escrow services or milestone-based disbursements tied to production progress. Request sample units for performance testing—particularly for conveyor speed, load stability, and integration compatibility—before committing to bulk orders. Analyze reorder rates and online revenue metrics as proxies for customer satisfaction and financial stability.

What Are the Leading Production System Suppliers?

| Company Name | Specialization | Product Range | Min. Order Value | On-Time Delivery | Avg. Response | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|

| Guangdong Huazhe Intelligent Manufacturing Co., Ltd. | Electronics, HVAC, Linear Conveyors | PCB Assembly, Double-Speed Chain, LED Display Lines | $1,000 | 33% | ≤2h | <15% | Yes – motor, belt, color, dimensions, logo |

| ARROW MACHINERY CO LTD | Food Processing – Plant Protein, Aquaculture Feed | TVP, Wet HMMA, Fish Feed Systems | $11,000 | Not available | ≤3h | Not available | Limited – model-specific configurations |

| Foshan Reinfa Agtech Co., Ltd. | Hydroponics, Vertical Farming | Lettuce Systems, Energy-Saving Farm Modules | $1,800 (10m²) | 100% | ≤6h | Not available | No – standardized modular units |

| Sichuan Mighty Machinery Co., Ltd. | Conveyor Systems – Food Grade, Industrial Rollers | PVC Belt, Wire Mesh, Slat-Top Conveyors | $800 | 86% | ≤6h | 33% | Yes – size, material, color, packaging |

| JCT DEVELOPMENT TECHNOLOGY COMPANY LIMITED | Adhesive & Packaging Production Lines | Hot-Melt Glue, Cooling, Block Adhesive Systems | $116,000 (2 pcs) | Not available | ≤2h | Not available | Engineered-to-order with full system integration |

Performance Analysis

Guangdong Huazhe and Sichuan Mighty stand out for strong customization and repeat business, with the latter achieving an 86% on-time delivery rate despite mid-tier responsiveness. Foshan Reinfa demonstrates perfect punctuality in fulfilling hydroponic farm modules, indicating reliable execution for standardized agri-tech deployments. ARROW MACHINERY targets niche food processing markets with high-ticket systems priced between $11,000–14,000, though limited reorder data suggests lower buyer retention. JCT Development offers the highest capital investment threshold ($58,000–88,000 per unit) for adhesive production systems, reflecting complex engineering requirements and low-volume, high-specification output. Buyers seeking automation integration should prioritize suppliers listing PLC controls, motor drives, and bi-directional operation features.

FAQs

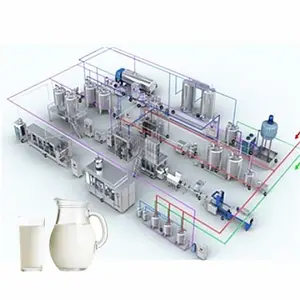

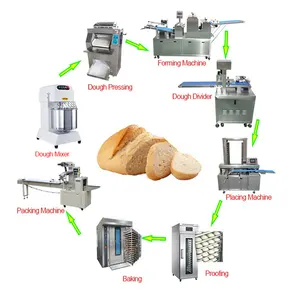

What are common types of production systems available from Chinese suppliers?

Key configurations include conveyor-based assembly lines (for electronics and appliances), continuous-flow food processing systems (plant protein, aquaculture feed), hydroponic vertical farming units, and automated packaging/adhesive production lines. Each type supports batch or continuous operation depending on throughput needs.

What is the typical MOQ and lead time?

Minimum order quantities typically start at one set or module, with prices ranging from $800 for basic conveyors to over $50,000 for integrated chemical or adhesive lines. Lead times average 30–45 days for standard models, extending to 60+ days for customized systems requiring engineering adjustments.

Can suppliers customize production systems?

Yes, many suppliers offer modifications in size, drive mechanism, belt material, color, and branding. Guangdong Huazhe and Sichuan Mighty provide extensive customization, while Foshan Reinfa focuses on pre-engineered modules with limited adaptability. Full engineering changes require direct consultation and technical drawings.

Are these systems compliant with international standards?

While formal certifications like CE or ISO are not universally declared, suppliers use industry-standard materials (SUS-304, food-grade PVC) and design practices aligned with functional safety and hygiene norms. Buyers must explicitly request compliance documentation for regulated environments.

How to evaluate supplier reliability without third-party verification?

Analyze delivery performance, response times, and transaction volume. On-time delivery exceeding 85%, response under 6 hours, and evidence of repeat customers (reorder rate >30%) correlate strongly with operational reliability. Request factory photos, process videos, and client references to validate claims.