Types Of Sensors Used In Manufacturing

Top sponsor listing

Top sponsor listing

About types of sensors used in manufacturing

Where to Find Suppliers for Types of Sensors Used in Manufacturing?

China remains a dominant hub for industrial sensor manufacturing, with key production clusters in Ningbo, Guangzhou, Shenzhen, and Yiwu offering specialized capabilities across sensing technologies. These regions host vertically integrated supply chains that support rapid prototyping, scalable production, and cost-efficient customization. Ningbo and Shenzhen excel in electronic and motion sensor fabrication, leveraging proximity to semiconductor foundries and PCB assembly lines. Guangzhou specializes in sensors for printing and material handling machinery, while Yiwu has emerged as a distribution nexus for automotive-grade sensors with streamlined export logistics to Europe and North America.

The concentration of component suppliers, contract manufacturers, and testing facilities within 50km radii enables faster time-to-market—typically 15–30 days for standard orders. Buyers benefit from localized sourcing ecosystems that reduce material costs by 20–35% compared to Western alternatives. The presence of dedicated R&D teams in leading firms supports advanced functionality integration, including IoT connectivity, analog-to-digital signal conditioning, and environmental resilience (IP67+ ratings).

How to Choose Suppliers for Industrial Sensors?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international standards such as ISO 9001 for quality management, CE marking for electromagnetic compatibility, and RoHS compliance for hazardous substance restrictions. For safety-critical applications (e.g., emergency shutdown systems), confirm functional safety certifications like IEC 61508. Request test reports for parameters including response time, operating temperature range (-25°C to +85°C typical), and mean time between failures (MTBF >50,000 hours).

Production and Engineering Capacity

Assess supplier infrastructure based on the following benchmarks:

- Minimum 3,000m² production area for high-volume output

- In-house design and tooling capabilities for custom housings, optics, and circuitry

- Surface-mount technology (SMT) lines and automated calibration stations

Cross-reference facility size with on-time delivery performance (target ≥97%) and reorder rates (>25% indicates strong customer retention).

Customization and Scalability

Evaluate flexibility in form factor, output signal (PNP/NPN, 4–20mA, 0–10V), mounting configuration, and cable length. Leading suppliers offer full OEM services—including logo labeling, packaging design, and private branding—with minimum order quantities (MOQs) as low as 1 piece for prototypes. Confirm availability of CAD models and datasheets for seamless integration into automation architectures.

Transaction Security and After-Sales Support

Prioritize suppliers with documented dispute resolution processes and third-party payment protection. Analyze historical performance metrics: response times ≤3 hours indicate robust customer service capacity. Post-delivery support should include technical documentation, calibration certificates, and failure analysis for defective units.

What Are the Top Suppliers for Types of Sensors Used in Manufacturing?

| Company Name | Main Product Categories | On-Time Delivery | Reorder Rate | Response Time | Online Revenue | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|

| Ningbo Yoursensor Electronic Technology Co., Ltd. | Motion & Position Sensors, Safety Sensors, Automatic Door Operators | 97% | 24% | ≤3h | US $580,000+ | Color, material, size, logo, packaging, graphic | Custom Manufacturer |

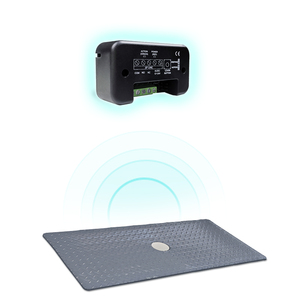

| Shenzhen Yingsitai Electronics Co., Ltd. | Motion Sensors, Pressure, Ultrasonic, Vibration, Current Sensors | 100% | <15% | ≤3h | US $30,000+ | Limited (BOM-level assembly) | Electronic Components Supplier |

| Yiwu Toutu Trading Firm | Auto Sensors, Engine Oil Level, Wheel Speed, Headlight Level | 98% | 43% | ≤3h | US $410,000+ | Not specified | Trading Firm |

| Guangzhou Keweiqi Trading Co., Ltd. | Color Mark Sensors, Ultrasonic Edge Guides, Web Guiding Systems | 80% | <15% | ≤4h | US $30,000+ | Not listed | Trading Company |

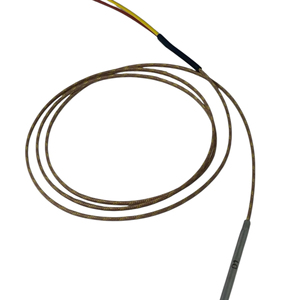

| Thermotron-Ce Technology Pte Ltd | Temperature Sensors, RTDs, Thermistors, Level Measuring Instruments | - | - | ≤12h | - | Material and housing variations | Manufacturer |

Performance Analysis

Ningbo Yoursensor stands out with balanced performance across delivery reliability (97%), revenue scale (>$580K), and comprehensive customization—ideal for buyers requiring branded, application-specific sensors. Shenzhen Yingsitai achieves perfect on-time fulfillment but serves niche electronics markets with lower repeat purchase rates, suggesting transactional rather than strategic buyer relationships. Yiwu Toutu demonstrates exceptional customer retention (43% reorder rate), indicating strong product fit in automotive sensor replacements. Guangzhou Keweiqi’s 80% on-time delivery is below industry benchmark, posing potential risk for time-sensitive automation projects. Thermotron-Ce focuses on high-precision temperature measurement but lacks verifiable transaction data, warranting due diligence before large-scale procurement.

FAQs

How to verify sensor supplier quality?

Cross-check ISO or CE claims with certification bodies. Request sample test reports for accuracy, hysteresis, and thermal drift. Conduct factory audits via video tour to confirm cleanroom assembly, automated optical inspection (AOI), and environmental stress screening protocols.

What are typical MOQs and lead times?

Standard sensors often have MOQs of 1–5 pieces with lead times of 7–15 days. Bulk orders (≥1,000 units) may require 25–35 days depending on customization. Prototypes can be delivered in 5–10 days if design files are provided.

Can suppliers integrate sensors into existing control systems?

Yes, many offer signal compatibility options (analog, digital, IO-Link) and mechanical adapters. Confirm pinout diagrams, communication protocols (Modbus, CANopen), and enclosure IP ratings match your system requirements prior to integration.

Do manufacturers provide free samples?

Sample policies vary. Established suppliers may offer one free unit for qualified buyers placing future volume orders. Otherwise, expect to pay 50–100% of list price, refundable upon order confirmation.

What materials are commonly used in sensor construction?

Housings are typically made from stainless steel (304/316), brass with nickel plating, or engineered plastics (PPS, PBT) for chemical resistance. Sensing elements use silicon-based MEMS, sapphire diaphragms, or platinum RTD coils depending on application demands.